I was trying real hard to fine-tune my 243. I thot I was going to move up in the league toward "High-End" shooters. :-(

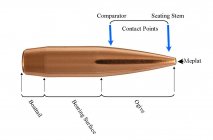

Using a Redding Big Boss ll, and Redding Type S bushing dies. Cases were all trimmed and very close. My focus was OGIVE length to be very consistent. Bla Bla Bla.

When I'm seating the projectile, my first stroke barely starts it. The I sping the case 1/4 turn, I rep[eat 2 more times so I push the projectile 4 times very gently. OCD

I'm shooting a Viper Gen 2, so I wanted to be really OCD. The tests 7-9 I expect to be over pressure so I quit loading 5 rounds.

I'm ready to pull the rounds, and reseat. Very disappointed. How would youz rate the variable lengths? Thanks

Using a Redding Big Boss ll, and Redding Type S bushing dies. Cases were all trimmed and very close. My focus was OGIVE length to be very consistent. Bla Bla Bla.

When I'm seating the projectile, my first stroke barely starts it. The I sping the case 1/4 turn, I rep[eat 2 more times so I push the projectile 4 times very gently. OCD

| ES | STDV | ||||||

| Test 1 | 2.2105 | 2.2075 | 2.2095 | 2.2080 | 2.2105 | 0.0030 | 0.0014 |

| Test 2 | 2.2080 | 2.2105 | 2.2100 | 2.2105 | 2.2060 | 0.0045 | 0.0020 |

| Test 3 | 2.2090 | 2.2095 | 2.2090 | 2.2105 | 2.2085 | 0.0020 | 0.0008 |

| Test 4 | 2.2085 | 2.2105 | 2.2085 | 2.2080 | 2.2070 | 0.0035 | 0.0013 |

| Test 5 | 2.2065 | 2.2080 | 2.2055 | 2.2070 | 2.2085 | 0.0030 | 0.0012 |

| Test 6 | 2.2080 | 2.2085 | 2.2070 | 2.2065 | 2.1955 | 0.0130 | 0.0054 |

| Test 7 | 2.2080 | 2.2030 | 2.2085 | 2.2045 | 0.0055 | 0.0027 | |

| Test 8 | 2.2060 | 2.2065 | 2.2060 | 0.0005 | 0.0003 | ||

| Test 9 | 2.2075 | 2.2085 | 2.2050 | 0.0035 | 0.0018 |

I'm shooting a Viper Gen 2, so I wanted to be really OCD. The tests 7-9 I expect to be over pressure so I quit loading 5 rounds.

I'm ready to pull the rounds, and reseat. Very disappointed. How would youz rate the variable lengths? Thanks