..okay, I did a simple google search on Sinclair's comparator = good or bad!

Bullet Prep — Giving You the Long Range Edge

Editors Note: This is the 1st part in a series of articles by Pete Petros in the methodology he uses to prepare his bullets for long-range shooting.

When it comes to precision reloading and shooting, the main goal is to ensure everything from start to finish in the reloading process is close to the same as possible. Most shooters think of this as choosing the best brass for the cartridge, sorting it by weight, and prepping it properly to attain replication in brass properties. Then by carefully weighing each powder charge and seating the bullet to the same depth each time, the finished products will act the same as they are fired through the barrel.

This is very true, and these steps along with many sub-steps in case preparation are critical to attaining the most consistent results out of a load, but let us back up a step.

What is the most important component in a loaded round? Many would argue it is the type of powder and charge being used. Others may say the brass choice or even the primer make the load. The most important component in the mix is definitely what will give the final results, and that is the bullet.

These days there are so many choices in bullet types and style in every caliber to get the job done. Some are known to perform better than others, and certain rifles will shoot certain choices better. In fact, most of the bullets available to the reloader today are all good quality and will get the job done. It is no secret that a high Ballistic Coefficient VLD (Very Low Drag) type bullet will shoot better at long ranges and cut through the wind better. But what can you as the shooter do to make your bullet choice even better?

In the same essence as modifying a stock engine in a car to enhance or increase performance, you can do the same to your choice projectile to squeeze a tad more performance out of it. There are a few steps that can be taken to do this quite simply. Flash back to the beginning of the article. We talked about brass sorting and prep prior to loading. The same goes for your bullet. Through sorting your bullets in the same lot and prepping them, you can tighten your groups dramatically, and make your “close to the same†loads even closer to being identical.

The absolute first step in bullet sorting by some reloaders is to sort the lot by weight. Even in the highest quality bullets you will find a few tenths of a grain spread or more in weights. Through sorting by weight you can split the entire lot up by variation.

The next step taken in bullet sorting is to take the lot of bullets planned on being loaded, and measure them by base to bullet ogive. You will notice that even in the highest quality bullets available there is a variance of a few thousands of an inch or more. Take your lot, and sort them by base to ogive length and group them together.

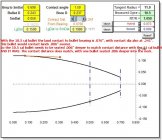

The secret to consistency in both of these tools is the most important rule to remember. Basically the softest material in the process is the copper jacket of the bullet being measured. It will give a few thousandths with the more pressure you put onto the base while inserting it into the comparator. What is important and critical to this is to make sure you use the same light but steady pressure on the bullet base while measuring. This is where the bullet Sinclair Bullet Sorting Stand excels. After you lift the indicator stem up, lower it (slowly and steadily) onto the bullet while in the comparator, it will give the same amount of pressure each time. Prior to measuring the bullet, lightly “seat†the bullet ogive into the comparator with your finger to “seat†the ogive, then proceed to measure. Repeat this the same way each time to attain similar results. A good tip from reloaders that have been using the stand is to use the pointed indicator end versus the included flat end. While measuring be sure that the point is centered on the bullet base. The flat end tends to be more inconsistent in measurements.

Once you are set up and ready to sort bullets, take a batch of ten of the bullets randomly out of the un-measured lot. Measure each one as described earlier. Write each measurement down on a piece of masking tape and lay out on a flat surface with the measured bullets on your workbench in order of what you found. When all are measured, repeat the process with the same ten until you see consistency in your recorded test lot. When you achieve the same results during the repeating process, you have a consistent technique, and are ready to sort the entire batch.

With the measurements taken from the ten test bullets find the average of the batch. This is most likely the same or close to the average of the entire box or lot you will be sorting. The average measurement will be your “0†batch. Take one of the average bullets, place it in the stand and zero out the indicator face so it shows “0†when it is being measured. Test it a few times again to make sure that the zero is true and consistent.

The next step is setting up a system of separating the measured bullets. A great way to do this is by using empty bullet boxes, or glad ware containers. Take your chosen containers and mark them with masking tape labeled “0 (average), -.001, -.002….+.001, +.002…and so forth depending on how wide the spread of measurements are. These numbers are the difference in thousandths of an inch, found from the average you found in the test sequence.

Now it is time to measure. Place each bullet in the appropriate container for what you find. Keep these measured batches together, and label them so you remember which batches are which for the next steps in the bullet prep process. (see picture above). Many will leave it here and go ahead with the reloading process. In the next installment of this article, I will outline the next steps that can be taken to maximize these sorted bullets even more for performance. These next steps are meplat trimming and bullet pointing. The final steps in tweaking the ultimate long range bullet, Keep your eyes peeled for the next part of this series in future Reloading Press newsletters!