Follow up post!! First let me say thanks to everyone that chimed in, I appreciate your input. Now the good news, I think my hypothesis of not having enough powder was correct. As per the suggestion of a few in this thread I conducted an experiment with higher powder charges.

I pulled the bullets from the remaining rounds I had loaded with 38.5gr and then reloaded 15 with 40gr and 13 with 41.5 gr. One of my theories was that I was somehow losing powder between the drop and filling the case. So while pulling bullets I took the time to measure the powder in those cases. I found I was within ±0.02gr of 38.5 just as expected.

I fired the rounds over the weekend and found my ES and SD had seemingly not really improved. Then I started to look at the data a little closer and found it was really only one or two rounds that threw the data off. I suspect this could be due to reseating the bullets or just variability due to the condition of the brass from previous firings. If I excluded those few rounds the ES and SD improved dramatically. I then starter looking at the fired cases. I noticed that were was no soot on the cases as before. I also measured case base to shoulder length (using a comparator) and the neck OD of every case. This is where things got really interesting.

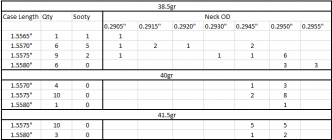

I found that the 22 rounds I had fired previously with 38.5gr varied in length from 1.5565" to 1.5580". I also noted that fewer of the longer cases had soot on them. When I measured the neck ODs I found they varied from 0.2905" all the way to 0.2955". The cases with larger neck ODs did not have soot. This clearly proved that my cases weren't expanding enough to seal when fired.

Next I measured the 15 rounds I had reloaded with 40gr. They varied in length from 1.5575" to 1.5580" with the majority being 1.5575". The case ODs were the really telling part as they only varied from 0.2945" to 0.2950". That's 0.004" larger than the smallest rounds fired with 38.5gr. The 13 rounds reloaded with 41.5gr showed the same pattern of longer lengths and larger neck ODs.

This all seems to suggest that 38.5gr of H4350 does not expand my cases enough to properly form a seal with the chamber. One could argue that simply pulling and reseating the bullets was what made the difference and not the low powder charge. I think however, the more logical answer is that the powder charge is not enough.

The reason it's not enough is also debatable. Is 38.5gr simply just not enough to expand brass in any condition? Is my chamber too big? Is my sizing die undersizing my brass in dimensions that aren't seen by my comparator? Is my brass too hard? Is it too hard because I'm over working it when sizing? Is it too hard because my annealing isn't working as intended? I intend to at least try to answer these questions before making any final conclusions. Most of them seem measurable without too much hassle. I'm trying my best to not let confirmation bias takeover but, it does certainly seem like it's just not enough powder.

View attachment 1603571