Admins, if this is in the wrong section please move to the correct section. I am just looking to help out Neil as I own a set of his dies and as a young shooter, would like to get future dies from him.

Gents,

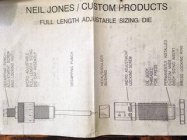

I just got done talking to Neil Jones on the phone. I'll be frank: He's 78 and looking for someone to take up the mantle of continuing his business. He makes a really unique die that I use for my 260 rem (and I love it). Unfortunately he isn't tech savvy and doesn't have a way to put out that he's looking for help and someone to pass his business along to.

He's looking for someone who has a passion for the business of making his custom dies. If anyone is interested give him a call. So far he's just been asking people that he knows but hasn't gotten much back.

So here is his information:

website: http://www.neiljones.com/

phone #: 814-763-2769

He lives in Saegertown, PA

Gents,

I just got done talking to Neil Jones on the phone. I'll be frank: He's 78 and looking for someone to take up the mantle of continuing his business. He makes a really unique die that I use for my 260 rem (and I love it). Unfortunately he isn't tech savvy and doesn't have a way to put out that he's looking for help and someone to pass his business along to.

He's looking for someone who has a passion for the business of making his custom dies. If anyone is interested give him a call. So far he's just been asking people that he knows but hasn't gotten much back.

So here is his information:

website: http://www.neiljones.com/

phone #: 814-763-2769

He lives in Saegertown, PA