Cheap chinese lathe everyone loves to talk crap about. Prior owner didn't have it on leveling feet, just the stands right on a shop floor. When I moved it to my shop and tried to level it (with feet), it had so much twist in it that the tailstock front feet could be unsupported and the front way woulds still measure high by many thousandths - was so far beyond my machinists level i had to use a wood level just to measure it. The first 6 inches were ok for use, but beyond that it would cut a monster taper.

A bunch of months of letting it settle, adjust, cut test bar and its come back to its happy place.

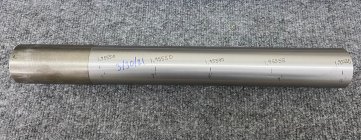

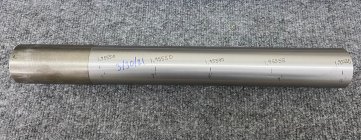

2 inch mild steel test bar sticking out far enough to make me nervous unsupported.

Once I got that cutting without a repeatable taper on <5 thou finish cuts. I borrowed Bamban's blake (which is an awesome tool) to get the tailstock dialed in near the chuck. Then I slid that sucker out 24 inches and cut another test bar totally unsupported in the middle aside from chuck and tail stock. Just took super light cuts .003 at the end to minimize deflection.

I didn't just do the ends/collars like a lot of guys do because I wanted to see how much deflection/push off a 1.25 inch rod would have in the middle and its defnitely measurable. The ends are 3 tenths off from eachother at 24 inches and being that long, I couldn't get a repeatable cut that measured inside that to even try and tweak it further.

Just for this thread, I broke out the level again to see where it stands now that the test bars are showing the truth. I always push the level up againt the carriage so its repeatably in the same orientation.

Close the headstock.

.

Down at the tailstock.

Its certainly not level, but its pretty close. There is almost no twist in the beds left at this point and its cutting straight. I'll check it again in another couple months to make sure its stopped moving on me now that the feet are all snugged up and should be fully supported.

A bunch of months of letting it settle, adjust, cut test bar and its come back to its happy place.

2 inch mild steel test bar sticking out far enough to make me nervous unsupported.

Once I got that cutting without a repeatable taper on <5 thou finish cuts. I borrowed Bamban's blake (which is an awesome tool) to get the tailstock dialed in near the chuck. Then I slid that sucker out 24 inches and cut another test bar totally unsupported in the middle aside from chuck and tail stock. Just took super light cuts .003 at the end to minimize deflection.

I didn't just do the ends/collars like a lot of guys do because I wanted to see how much deflection/push off a 1.25 inch rod would have in the middle and its defnitely measurable. The ends are 3 tenths off from eachother at 24 inches and being that long, I couldn't get a repeatable cut that measured inside that to even try and tweak it further.

Just for this thread, I broke out the level again to see where it stands now that the test bars are showing the truth. I always push the level up againt the carriage so its repeatably in the same orientation.

Close the headstock.

.

Down at the tailstock.

Its certainly not level, but its pretty close. There is almost no twist in the beds left at this point and its cutting straight. I'll check it again in another couple months to make sure its stopped moving on me now that the feet are all snugged up and should be fully supported.

Last edited: