When it comes to up/down cal changes, it seems pretty much trial & error to find resultant neck thickness.

I turn NEW necks trial & error before up or downsizing to a different cal. This, because it is far easier to turn new/unsized necks.

But it just dawned on me that this thickness problem should be easy to calculate.

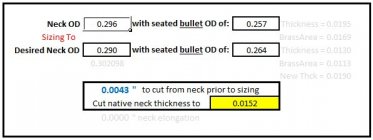

So I just put a spreadsheet together to do it.

Basically, I'm determining brass area for an entered cal & measured .xxx thickness. Given that brass area will not change with up/down sizing, a new neck diameter with the same brass area must be at .yyy thickness.

I turn NEW necks trial & error before up or downsizing to a different cal. This, because it is far easier to turn new/unsized necks.

But it just dawned on me that this thickness problem should be easy to calculate.

So I just put a spreadsheet together to do it.

Basically, I'm determining brass area for an entered cal & measured .xxx thickness. Given that brass area will not change with up/down sizing, a new neck diameter with the same brass area must be at .yyy thickness.