Fast14riot

Gold $$ Contributor

Simple me thinks using a drill motor and trigger controls would be simpler. But, programmer I am not. I leave that for the missus, lol!

It would be simpler but it would not have the resolution I want or things like go home or the atmospheric sensors and display. I'm going to try and have the display show level, temp, pressure and humidity.Simple me thinks using a drill motor and trigger controls would be simpler. But, programmer I am not. I leave that for the missus, lol!

No problem. Be glad to pass along anything I have learned. I would use a stepper motor to move your project. They are inexpensive, readily available and code is available to use for the project. They also have a holding torque. The size would probably be determined by how much holding torque you need. What thread are you using to drive the movement?I have not started that part yet, I figured I would get the form down first. If I have any questions would you mind me asking?

Kris

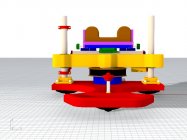

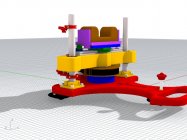

Look at nema and 17 or 23 steppers. You could mount them recessed into the base plate and really shorten the overall height if needed. It sounds funny but you might look at the lower powered motors for a frame size as they are shorter in length. At the same holding torque a nema 23 may be shorter than a nema 17. I rally don’t think you will need much motor.I have not started that part yet, I figured I would get the form down first. If I have any questions would you mind me asking?

Kris

The motors I have now are worm gear. They are a smaller version of what is being used on brass and bullet collators. The windage is run on a rack and pinion.Look at nema and 17 or 23 steppers. You could mount them recessed into the base plate and really shorten the overall height if needed. It sounds funny but you might look at the lower powered motors for a frame size as they are shorter in length. At the same holding torque a nema 23 may be shorter than a nema 17. I rally don’t think you will need much motor.

Are you going to run one screw or two on the windage?

Chip

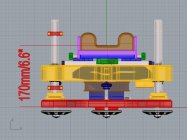

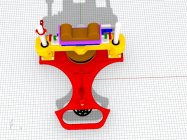

I did this yesterday in the cad model. I'm waiting on some more filament. Once it arrives I will print the new version.Can you lower the rest about 3 inches ?