Actually i do have a hardness tester but have never tested cartridge brass. I do know if you size 100 at the same time, seat some recording the pressure required then seat the rest after some time it is different. As an engineer i do know that testing yields different results than on paper sometimes

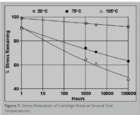

https://www.copper.org/applications/industrial/DesignGuide/performance/timestress03.html

This article was referring to electrical connectors stamped out of cartridge brass. Don't know the relationship of stress to actual hardness. I worked with many types of hardness tester instruments over the years. Hardness testers use ASTM STANDARD certified test blocks made from steel or brass depending on the hardness range. Test instruments are required to be verified with test blocks every day before use. Most test blocks are certified +/- .5 or 1.5 hardness units variation from there intended test value. The high hardness blocks have a tighter range than the softer blocks. A typical brass 80 HRB +/- 1.5 certified test block never exceeds it's stated hardness range over the life of the test block.