You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe chucks

- Thread starter Acsr

- Start date

jackieschmidt

Gold $$ Contributor

I can chuck something up in a four jaw independent as easily as anything, but for barrel work, I use a 3 jaw Set True strictly for convenience.

Thanks everyone for the help!! Much appreciated. Maybe this HV Barrel is just a pain in the back side! I’ll keep on keeping on with the ol 4 jaw.

Thanks again ACSR

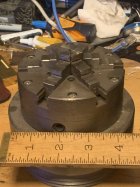

The only way to conquer it is to keep at it until you know it like the back of your hand. A lot of folks use a 6-jaw, or even a 3 jaw as it centers the work, but a 4-jaw is more accurate. I use a 4-jaw Buck mostly. This is an 8" with 2 piece jaws. Come to think of it, I have an old Skinner 6" combination chuck, it will allow for independence jaws, or will open/close all at the same time. No pics of that one.

I also have a few Skinner 4-1/4" 4-jaw chucks. I've long been attracted to these little cuties. It has fairly wide jaws for a small 4-jaw.

Another Skinner 904, I don't want to say I collect these, but if you know of any for sale, contact me.

This one is kinda cool, it's a 4" Buck 6-jaw chuck with an L0 backplate. Yes, it's an odd backplate, but I got it from Tom Lipton of oxtools, he just happened to have an adjust true for an L0 spindle nose to fit a 4" Buck.

There's lots of great choices out there, good luck on making the right choice for you!

I found yet another Skinner 904-52. I guess I have a chuck problem...

Last edited:

LVLAaron

Gold $$ Contributor

"Come to think of it, I have an old Skinner 6" combination chuck, it will allow for independence jaws, or will open/close all at the same time. No pics of that one."

That's intriguing. How does it go from independent to in unisen?

They don't go from one to the other... they are both.

They have a scroll like a 3 jaw, and independent jaws on top of that. They're thick boys, and seem like a real pain in the ass to use on a regular basis, unless you're constantly chucking random sized stuff

Bison

Alex Wheeler

Site $$ Sponsor

Sacrificial metal shims or rings and independent jaws create an issue most dont consider. You may dial the barrel in statically. But the force each jaw applies is not the same and those forces will want to settle out once a load is applied to the work piece.

Acsr

Silver $$ Contributor

I like the sound of this, convenience, specially working a full time job.I can chuck something up in a four jaw independent as easily as anything, but for barrel work, I use a 3 jaw Set True strictly for convenience.

They don't go from one to the other... they are both.

Yes, you either use them independent or with the scroll, it will operate both at the same time. The Skinner is not as big as the Bisons, but mine is only a 6". The independent work as a 4-jaw, with a key and worm screw for each jaw. But the scroll key turns the scroll which moves all of the jaws together. There are 5 chuck keys in total. Didn't mean to mislead anyone. This technology has been around for ages, I think my chuck is from the 40s or 50s. More useful than a chuck is to make a Cat's Eye out of a section of DOM. It functions as a chuck for barrels.

Here's the one that Bob Pastor sells. Bob does sell those set screws with brass tips that McMaster-Carr has. Those are not that expensive, if you make your own it's worth buying those, IMO. @Acsr, this would be a good project for you.

Viper 3 in 1 Bolt, Action Truing and Chambering Fixture — Viper Bench Rest

Bolt Truing Fixture, Chambering Fixture and Action Truing Fixture. "Truly a 3 in 1 Fixture" This is the one originally designed by “The Viper, Bob Pastor”. If it is from Viper, it will have our name on it! Used by the U.S. Marine Corp Shooting Team gunsmiths. Don’t be fooled by imitations

Replacement Parts — Viper Bench Rest

Replacement screws for Viper Chambering fixture. We do ship outside the US please contact us through the Contact Us page we will be happy to get the best shipping rates for you!! For product questions, cancellations or returns please contact us through the “Contact” page. All of our pr

Last edited:

A piece of DOM that could work for a fixture, and not break the bank, search for item 335541310094 on Ebay. You really only need about 1/3rd that much. 12" would be overkill, IMO. (I don't know if I'm allowed to link to Ebay here...)

EDIT:

Here's a link to some .5" wall DOM on the Online Metal site. Keep in mind, these are carbon steel, not aluminum as Pastor's. This leaves you open for creativity.

EDIT:

Here's a link to some .5" wall DOM on the Online Metal site. Keep in mind, these are carbon steel, not aluminum as Pastor's. This leaves you open for creativity.

Last edited:

LVLAaron

Gold $$ Contributor

I use 1/8th inch aluminum shims on each jaw. I've shaped them so the barrel can pivot as freely as possible... but I've noticed this in practice. I can get a barrel dialed in perfect pretty quickly... wait 5 minutes and things shift (maybe a tenth or two) .. I assume it's the shims settling, the grease in the scrolls moving, etc. I take a couple minutes and go through my checklists, pet the dog, etcSacrificial metal shims or rings and independent jaws create an issue most dont consider. You may dial the barrel in statically. But the force each jaw applies is not the same and those forces will want to settle out once a load is applied to the work piece.

I want to get a set of jaws setup like Area419 does:

This seems the least worst compared to a true bore. Copper wire rings... dont waste your time.

They don't go from one to the other... they are both.

They have a scroll like a 3 jaw, and independent jaws on top of that. They're thick boys, and seem like a real pain in the ass to use on a regular basis, unless you're constantly chucking random sized stuff

Bison

www.bison-america.com

Yeah very interesting! Never seen one like that before.

I like the idea of a 3 jaw buck chuck more than a 4 jaw. Thinking that a 3 jaw would provide more even pressure.

Either way. A good inboard and outboard spider works well. I made one similar to the picture. Cap head bolts flush with the outside, 1.35" ID hole to reduce entanglement points. Tapped 16x1mm pitch threads (5/8x25-ish so pretty fine) then cut down and screw cut 12.8 grade bolts to be a snug fit to the tapped threads. Made the outboard spider take the same thread pitch so you get the same travel per tweak. Doing it again I wouldn't use a back plate. By the time you stuff around mating the back plate to the spider properly it's not much more work to match it to the spindle nose, if you have a decent mill.

Attachments

DaveTooley

Gold $$ Contributor

For my 10X30 Nardini and 14X40 Clausing Metosa I turned down a backing plate and tapped that to shorten up the distance through the headstock. For my Haas I made it from single piece of aluminum.Yeah very interesting! Never seen one like that before.

I like the idea of a 3 jaw buck chuck more than a 4 jaw. Thinking that a 3 jaw would provide more even pressure.

Either way. A good inboard and outboard spider works well. I made one similar to the picture. Cap head bolts flush with the outside, 1.35" ID hole to reduce entanglement points. Tapped 16x1mm pitch threads (5/8x25-ish so pretty fine) then cut down and screw cut 12.8 grade bolts to be a snug fit to the tapped threads. Made the outboard spider take the same thread pitch so you get the same travel per tweak. Doing it again I wouldn't use a back plate. By the time you stuff around mating the back plate to the spider properly it's not much more work to match it to the spindle nose, if you have a decent mill.

BuffaloBill

Silver $$ Contributor

Doug Beach

Silver $$ Contributor

I bought the Grizzly spider. Threw out the screws it came with, and drilled / tapped it 1/2-40. Made some screws to match, and bronze TIG’d 7/16 ball bearings to the ends. Made bushings, using a 7/16 ball mill for the ball bearings to seat in.

It all works great, and the 40 tpi makes fine adjustments very controllable.

It all works great, and the 40 tpi makes fine adjustments very controllable.

One trick that may help is putting the chamber end on your tailstock center and then rough dial the muzzle in. Then, snug the 4 jaws lightly on the barrel chamber end. Should give you a fairly close starting point. Usually within .002 to .003 in my experience. Just a thought. Good luck.Been using a 4 jaw chuck, takes me a long time to dial in a barrel, is there a better option as far as chucks go? Any tips would be very much appreciated.!

Thanks ACSR

Paul

I do the same as @boltfluter, using a tailstock center to rough center the muzzle.

It also makes it easier to insert the rocking shims onto the ball bearings on the ends of the adjustment bolts in the inboard spider.

I used a back plate when I built the spider. I thought I could just drill and tap the D1-6 backplate for the spider bolts but, IIRC, the D1-6 camlock pattern wouldn't allow 4 bolt spider pattern.

Thinking back on it now, I think I could have just used a three camlock pattern, like @ridgeway, directly on the spider eliminating the backplate.

It also makes it easier to insert the rocking shims onto the ball bearings on the ends of the adjustment bolts in the inboard spider.

I used a back plate when I built the spider. I thought I could just drill and tap the D1-6 backplate for the spider bolts but, IIRC, the D1-6 camlock pattern wouldn't allow 4 bolt spider pattern.

Thinking back on it now, I think I could have just used a three camlock pattern, like @ridgeway, directly on the spider eliminating the backplate.

Last edited:

For the face plate I modified the bolts with ball bearings and made adapters based on barrel diameter. The adapters were flipped over and punched with a ball nose endmill same size as ball bearings and this allows the barrel to pivot when making outboard spider adjustments

Attachments

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.