You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Indicating Barrels to chamber

- Thread starter rickhirsch

- Start date

Lucky Shooter

Gold $$ Contributor

You guys have shown me that taper boring isn't the only way to go. I'm

very comfortable with it but its time I tried straight boring.

I have a slightly modified 220 Beggs reamer.

Shoulder diameter .404"

Web diameter at .125" .441"

Shoulder depth 1.072"

Any recommendations on how to drill and bore ? It appears the worst case

would only require having to part off a bit over 1" on the breech end.

Thanks.

A. Weldy

very comfortable with it but its time I tried straight boring.

I have a slightly modified 220 Beggs reamer.

Shoulder diameter .404"

Web diameter at .125" .441"

Shoulder depth 1.072"

Any recommendations on how to drill and bore ? It appears the worst case

would only require having to part off a bit over 1" on the breech end.

Thanks.

A. Weldy

urbanrifleman

Site $$ Sponsor

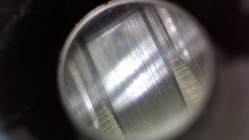

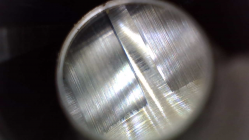

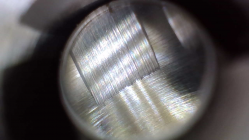

There is an expression that is used when gathering data, it is called "IN THE NOISE". The point where data is essentially indiscernible because the measuring devices are not capable of measuring any smaller or the material is not capable of any smaller tolerance.

These chambers are "in the noise" from the appearance. Which is pretty darn impressive.

These chambers are "in the noise" from the appearance. Which is pretty darn impressive.

There is an expression that is used when gathering data, it is called "IN THE NOISE". The point where data is essentially indiscernible because the measuring devices are not capable of measuring any smaller or the material is not capable of any smaller tolerance.

These chambers are "in the noise" from the appearance. Which is pretty darn impressive.

I had been shopping for many months for a "good lathe" based on what you read and hear from guys. When this lathe came up only 15 minutes from me I figured I'd take a chance and re-sell it if it was a totally piece of crap. Aside from some minor inconveniences I noted in another thread, I'm pretty darn happy for a used $3200 Grizzly!

DR_2297

Silver $$ Contributor

What is a number but a value given by a measuring instrument. MSA is a real thing and often times the noise is deafening.There is an expression that is used when gathering data, it is called "IN THE NOISE". The point where data is essentially indiscernible because the measuring devices are not capable of measuring any smaller or the material is not capable of any smaller tolerance.

These chambers are "in the noise" from the appearance. Which is pretty darn impressive.

urbanrifleman

Site $$ Sponsor

What is a number but a value given by a measuring instrument. MSA is a real thing and often times the noise is deafening.

There are entire systems in Six Sigma to test the tests. Most "measurements" are not repeatable to the tolerances people claim. Every operator will measure differently and claim they held this tolerance or that. In most small operations, no one really knows the capability of their measuring instruments. Few are going to have their gauges certified regularly.

Interestingly enough, I think the best test I see for aligned chambers is just looking at the throat with a scope. You can clearly see "straight".

Even then, appearances can be deceiving if you really nit pick. The assumption being the barrel is perfect.

Dusty Stevens

Shiner

DR_2297

Silver $$ Contributor

There are entire systems in Six Sigma to test the tests. Most "measurements" are not repeatable to the tolerances people claim. Every operator will measure differently and claim they held this tolerance or that. In most small operations, no one really knows the capability of their measuring instruments. Few are going to have their gauges certified regularly.

Interestingly enough, I think the best test I see for aligned chambers is just looking at the throat with a scope. You can clearly see "straight".

Even then, appearances can be deceiving if you really nit pick. The assumption being the barrel is perfect.

I am a DMAIC SS Black Belt so yeah...

urbanrifleman

Site $$ Sponsor

sometimes you gotta put a long freebore bore rider in a 5r barrel. The most fun you can have with a barrel

View attachment 1235368View attachment 1235370View attachment 1235371

Is a long freebore harder?

sometimes you gotta put a long freebore bore rider in a 5r barrel. The most fun you can have with a barrel

Now that looks friggen slick!

Dusty Stevens

Shiner

Thats right off the reamer before my break inNow that looks friggen slick!

Ok ! Alex I have a few questions.You made the statement about not owning a lathe with .0001 runout on the bearings.now are you determining this by an indicator on the spindle bore ?

Alex Wheeler

Site $$ Sponsor

I do not care about spindle bore. Just the bearings,

I have only chambered nine barrels. I made a rookie mistake on barrel #3 and had to put it back in and dial in again. The reamer holder "hung up" and I wound up with a chamber .002" oversized in the back, though the throat looked good. My first match with it I was first for six target agg (3 LG and 3 HG). At a later match I shot three consecutive sub 2" three-shot groups at 1000 yds on tuning day. Over the next two days my six target agg was 5.37", good for third place.

I chambered a 33-28 Nosler that gave me a 1/2" group at 100 yds with hunting bullets. Subsequent tall target testing validated that.

My current LG barrel has won me a couple of 600 yd matches.

In short, my own chambered barrels have shot as well for me as the barrels I had chambered by real gunsmiths. When I look at my throats they look even.

That said, I do not pretend to be close to the level of @Alex Wheeler, @DaveTooley, @butchlambert, @Dusty Stevens, and the rest of the real gunsmiths that post here. However, I seem to be on the right path, and maybe my experience can help fellow newbies like @urbanrifleman and others.

I dial in through the headstock (PM 1340GT Lathe) with plain old 4-Jaw and an outboard spider I made. I first get the barrel reasonably straight though the headstock. I do that by indicating the outside of the barrel to within a half thousandth.

I then get it as close as I can using a Grizzly rod, checking at the breech and a little past the throat. I use a Mitituyo .0001" test indicator on the rod. When I have it as good as I can get it, usually about .0002", I check the throat with the long reach Interapid. If it's not exact I go back to the Grizzly rod and work some more. When the Interapid says it's good I start machining. I am not good enough yet to adjust directly off the Interapid.

I cut the tenon, and recheck dial in. I thread and recheck the dial in. I then chamber with a snug but free bushing. My first pre-drilling and boring attempt was not successful.

I chamber .050 to .100 at a time at first, then take lesser cuts as I get deeper in. I pull the reamer completely out each pass, clean all the chips off the reamer and out of the bore. This is a slow process. When I get close I go even slower and check fit.

This is working so far, but I am not through improving and developing my technique.

And yes, the Noga indicator stands rock.

I chambered a 33-28 Nosler that gave me a 1/2" group at 100 yds with hunting bullets. Subsequent tall target testing validated that.

My current LG barrel has won me a couple of 600 yd matches.

In short, my own chambered barrels have shot as well for me as the barrels I had chambered by real gunsmiths. When I look at my throats they look even.

That said, I do not pretend to be close to the level of @Alex Wheeler, @DaveTooley, @butchlambert, @Dusty Stevens, and the rest of the real gunsmiths that post here. However, I seem to be on the right path, and maybe my experience can help fellow newbies like @urbanrifleman and others.

I dial in through the headstock (PM 1340GT Lathe) with plain old 4-Jaw and an outboard spider I made. I first get the barrel reasonably straight though the headstock. I do that by indicating the outside of the barrel to within a half thousandth.

I then get it as close as I can using a Grizzly rod, checking at the breech and a little past the throat. I use a Mitituyo .0001" test indicator on the rod. When I have it as good as I can get it, usually about .0002", I check the throat with the long reach Interapid. If it's not exact I go back to the Grizzly rod and work some more. When the Interapid says it's good I start machining. I am not good enough yet to adjust directly off the Interapid.

I cut the tenon, and recheck dial in. I thread and recheck the dial in. I then chamber with a snug but free bushing. My first pre-drilling and boring attempt was not successful.

I chamber .050 to .100 at a time at first, then take lesser cuts as I get deeper in. I pull the reamer completely out each pass, clean all the chips off the reamer and out of the bore. This is a slow process. When I get close I go even slower and check fit.

This is working so far, but I am not through improving and developing my technique.

And yes, the Noga indicator stands rock.

butchlambert

Site $$ Sponsor

I have only chambered nine barrels. I made a rookie mistake on barrel #3 and had to put it back in and dial in again. The reamer holder "hung up" and I wound up with a chamber .002" oversized in the back, though the throat looked good. My first match with it I was first for six target agg (3 LG and 3 HG). At a later match I shot three consecutive sub 2" three-shot groups at 1000 yds on tuning day. Over the next two days my six target agg was 5.37", good for third place.

I chambered a 33-28 Nosler that gave me a 1/2" group at 100 yds with hunting bullets. Subsequent tall target testing validated that.

My current LG barrel has won me a couple of 600 yd matches.

In short, my own chambered barrels have shot as well for me as the barrels I had chambered by real gunsmiths. When I look at my throats they look even.

That said, I do not pretend to be close to the level of @Alex Wheeler, @DaveTooley, @butchlambert, @Dusty Stevens, and the rest of the real gunsmiths that post here. However, I seem to be on the right path, and maybe my experience can help fellow newbies like @urbanrifleman and others.

I dial in through the headstock (PM 1340GT Lathe) with plain old 4-Jaw and an outboard spider I made. I first get the barrel reasonably straight though the headstock. I do that by indicating the outside of the barrel to within a half thousandth.

I then get it as close as I can using a Grizzly rod, checking at the breech and a little past the throat. I use a Mitituyo .0001" test indicator on the rod. When I have it as good as I can get it, usually about .0002", I check the throat with the long reach Interapid. If it's not exact I go back to the Grizzly rod and work some more. When the Interapid says it's good I start machining. I am not good enough yet to adjust directly off the Interapid.

I cut the tenon, and recheck dial in. I thread and recheck the dial in. I then chamber with a snug but free bushing. My first pre-drilling and boring attempt was not successful.

I chamber .050 to .100 at a time at first, then take lesser cuts as I get deeper in. I pull the reamer completely out each pass, clean all the chips off the reamer and out of the bore. This is a slow process. When I get close I go even slower and check fit.

This is working so far, but I am not through improving and developing my technique.

And yes, the Noga indicator stands rock.

Use what ever method makes you warm and fuzzy. Your rifle shoots best when you have confidence in your method.

Alex a couple of questions

The first halve of my working life I was a job shop machinist doing a lot of close tolerance aerospace work with some cylindrical grinding. I know when you come in the morning when the heat was turned down to 50

it might take a couple of hours for machine temps to stabilize and run consistent.

Do you maintain a constant temperature in your shop?

Do you run the lathe to warmup the spindle before you begin doing barrel work.

The first halve of my working life I was a job shop machinist doing a lot of close tolerance aerospace work with some cylindrical grinding. I know when you come in the morning when the heat was turned down to 50

it might take a couple of hours for machine temps to stabilize and run consistent.

Do you maintain a constant temperature in your shop?

Do you run the lathe to warmup the spindle before you begin doing barrel work.

Alex Wheeler

Site $$ Sponsor

Spindles on manual machines do not run anywhere near the speeds of cnc. The bearing housing temp difference from room temp to the time I finish a barrel is minor. And if your checking your work you already know your machine and you will already know if things move from room temp to warm. My bearings are set up with preload because I run low speeds. Neither of my lathes move from cool to warm so far as spindle run out is concerned. I am surprised how often I have to explain the difference between one part, and a production run. All that matters is that the bore is running as close to zero runout as possible right before you prebore and ream. I dont care what temp it is. The difference is we dial in every one every time. Im a bit worn out on this topic for now.

urbanrifleman

Site $$ Sponsor

Use what ever method makes you warm and fuzzy. Your rifle shoots best when you have confidence in your method.

"The Warm and Fuzzy Method"

by

Butch Lambert

Now, that is a book I would buy....

DaveTooley

Gold $$ Contributor

Total spindle run time on my Haas is about 5 minutes for a chamber not including low speeds when I run the finish reamer in. Difficult to get the temperature up on the bearings. Then there's work piece deflection in a spider which isn't there when running a reamer in.

Similar threads

- Replies

- 74

- Views

- 11,382

- Replies

- 11

- Views

- 8,116

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.