First question. You gunna shoot factory loaded ammo or roll your own?

Factory loaded ammo? Get a gauge. Home rolled, set the head space to YOUR ammo.

You will probably NOT be changing barrels that often so maybe think about passing on an action wrench?

Got a Wheeler Action wrench. It clamped the action to the barrel so tight that I had to take it off to turn the barrel out of the action. Used it once then stuck it under the bench, never to be used again.

Have changed a BUNCH of barrels with no action wrench needed.

A good WRAP with a steel hammer on the nut wrench will break it loose. You can pull and cuss all you want and it may never break loose!!

Same going back on. Set the head space, SMACK the nut wrench with a STEEL hammer, double check the head space and go shooting.

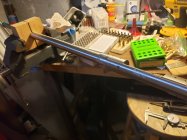

Barrel clamped in the vice in a thick rag will hold it enough to break the nut loose. Once loose, reverse the process.

First time? Might consider a smith to break the nut loose. From then on, nothing to it.

Again, "steel hammer" to SMACK the nut wrench to loosen and re tighten. The SHOCK of the SMACK (steel on steel) will loosen and tighten the nut. NEVER had any of mine come loose!!

Nut torque? Think snug than the steel on steel SMACK!!