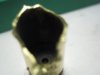

I've got around 10 reloads per case and I'm having to start culling cases (~20%) due to incipient case head separation. Attached is a not so good photo of a case I ripped apart to show what I was feeling with my paper clip tool.

Most of the loads on this brass were with what I consider a moderate 260 load (140gr hornady bthp, 41.5gr of IMR4451 @ 2800 fps). Recently I settled on a warmer load but only have a couple loads of this newer load (140gr hornady eld-m, 42.8gr of IMR4451@2930 fps). These velocities are from a 30 inch barrel.

I'm curious to see how everyone else is doing.

PS. I'm full length resizing every reload with a standard rcbs die. Do you think neck sizing would help?

Most of the loads on this brass were with what I consider a moderate 260 load (140gr hornady bthp, 41.5gr of IMR4451 @ 2800 fps). Recently I settled on a warmer load but only have a couple loads of this newer load (140gr hornady eld-m, 42.8gr of IMR4451@2930 fps). These velocities are from a 30 inch barrel.

I'm curious to see how everyone else is doing.

PS. I'm full length resizing every reload with a standard rcbs die. Do you think neck sizing would help?