I've been shooting a 6mm Comp Match for several years. I've loaded approximately 3000 rounds in that amount of time.

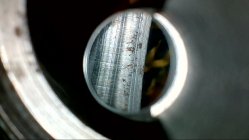

This past spring when I was loading up some practice rounds I noticed that my sized brass was coming out of the die scratched. The scratches are parallel to the axis of the case, and at several points around the circumference of the case. It had been a while since I cleaned the dies so I tore them down and took a look. There where huge brass streaks in the die. I cleaned the die, which ended up being a hassle. I had to use wipe out to get rid of all the brass in the dies. Then I hit them with break cleaner followed by One Shot cleaner/lube. I inspected the dies again. Brass streaks are gone, but I can see pits/burrs in the die body. Using a cotton swab you can easily feel these areas. I'm going to call Redding this week and see if they can hone that out and return the die.

My reloading procedure for this brass (after being fired) has been:

Was the brass not clean enough? Lube issue? Die not cleaned often enough.

I want to avoid this mistake in the future.

Thanks,

Ross

This past spring when I was loading up some practice rounds I noticed that my sized brass was coming out of the die scratched. The scratches are parallel to the axis of the case, and at several points around the circumference of the case. It had been a while since I cleaned the dies so I tore them down and took a look. There where huge brass streaks in the die. I cleaned the die, which ended up being a hassle. I had to use wipe out to get rid of all the brass in the dies. Then I hit them with break cleaner followed by One Shot cleaner/lube. I inspected the dies again. Brass streaks are gone, but I can see pits/burrs in the die body. Using a cotton swab you can easily feel these areas. I'm going to call Redding this week and see if they can hone that out and return the die.

My reloading procedure for this brass (after being fired) has been:

- Tumble ( I think the latest bucket of media is walnut)

- Anneal

- Lube (Dillon or Frankford Arsenal lanolin type)

- Size

- Prime

- Charge

- Seat

Was the brass not clean enough? Lube issue? Die not cleaned often enough.

I want to avoid this mistake in the future.

Thanks,

Ross