I just find it harder to determine how much time it take to get the right amount of anneal. With flame annealing, how the neck glows tells me a lot about timing regardless of brass thickness.I would like to understand why salt bath annealing wouldn't provide a more consistent temperature than flame annealing?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with lower SD

- Thread starter Eferg

- Start date

I think you're overstating that by a lot. Going from an SD of 20 to 5 will improve groups by a lot, even at 100 yds, assuming the shooter if proficient. Going from a 15 to 12 or an 8 to a 5, one isn't likely to see much difference. And as I mention, it true that the lowest SD isn't going to say which load works best. But one isn't going to have consistent tight groups with high SD's.Some might be inclined to think that going from a SD of 20 to 5 will improve their group dramatically. It usually doesn't work that way.

The only problem with SS pins is getting the inside to the necks too clean. . . if one considers that a problem. The problem in wet tumbling is the cases themselves banging against each other on the narrow case mouths, especially those that have been chamfered and deburred. And especially bad if they're banging together over a long period of time. Whenever I wet tumble (not part of my normal procedure), it's only for 20-30 minutes using very hot water with Dawn and some Lemi-Shine and they come out nice and clean with no big issue on peening the mouths. Of course, chamfering afterwards always takes care of any peening anyway.I'd stop using the stainless pins. They can do more harm than good in worse case - but if you want to tumble,

old_heli_logger

Gold $$ Contributor

Those magnum primers are your problem. Try any non-magnum primer.... don't ask me how I know

CF Junkie

Gold $$ Contributor

First things first.

15 fps SD usually indicates a max deviation of between 45 to 50 fps. That is what factory ammo generally measures for me.

My best reloads have gotten me an SD of 5 to 7 fps, about 15 to 21 fps max deviations, and my reloads are kept to Bullet Base to Ogive of =/- 0.0005 difference across 25 reloads with a powder charge measured to 0.1 grains.

The variations in velocity, even using the most accurate reloading techniques are due to the variations that occur in the primer/powder ignition process. Primers fire, not always the same way, into a powder load that may or may not be touching the powder charge with the same amount of powder since powder density in the cartridge is impacted by the cartridge lying flat in the chamber. The powder burn rate generates pressure and it can vary based upon temperature. It is that pressure that pushes the bullet out of the neck and propels it down the barrel. Consider the variations that can occur in that process and you can see why there can be differences in bullet velocity when it exits the muzzle. That results in the measured velocities that are represented in the SD calculation.

Powder load for your .308

A load of 45 grains of Varget with a 165 TGK creates pressure that is 98% of Pmax. I have never had any rifle shoot accurately when the pressure gets that close to Pmax. I would suggest a load around 42.9 to 43.0 grs of Varget that would get you to about 85 to 86% of Pmax with bullets seated at the recommended OAL. I would suspect that the reduced recoil and the lower pressure will help with the group sizes and also improve the life of your primer pockets and the brass in general.

Some recommendations:

My data gathered from over 74,000 reloads over the last 18 years, shows that SD is not the big factor in accuracy. Neither is using pins in tumbling, and such, but I have found that my inability to consistently set up in the exact same position after each shot makes the difference in accuracy.

If you want to see the impact that you, as the shooter, make to your accuracy, measure the SD of 20 of your 5-round group sizes with the same load with your rifle. If it isn't 0.040 or less, you have a lot of accuracy improvement possible just by eliminating your 'shooter induced variations'. That will give you more improvement in accuracy than improving your SD from 15 to 7 fps.

About 5 years ago, I took about a year to improve my shooting technique, primarily by ensuring that I was in the same position each time I pulled that trigger. My group sizes are now 2/3rds of what they were.

All of the following data was gathered using the exact same front rest, a Sinclair F-class bipod, and a Protektor rear rest. All were shot at 100 yards at the same range.

My $320 bargain Savage 12 FV .223 1:9 twist, out of the box, averaged 0.341 for 86 groups with a group size SD of 0.090.

I changed to an Oryx chassis because the factory bargain stock didn't have any stiffening and would twist under recoil. With the new chassis, and with working on my technique, the average dropped to 0.273 for 1446 groups with a group size SD of 0.052.

I continually worked on getting set up consistent, and even with my occasional trigger jerk or loss of concentration. The last 4 months of shooting averaged 0.257 for 108 groups with a group size SD of 0.035.

I didn't change any reloading techniques, I tumbled my brass with pins, used 5 different powders, and 18 different bullets. With the new Oryx Chassis, and over 1446 groups there were some differences in accuracy with different bullets and powders, but they were actually not all that great, within 0.020 group size differences. Over several years, the changes in SD of my group sizes were mostly due to eliminating my 'shooter induced variations'.

I know we often try to resolve problems by blaming bullets, powder, reloading techniques, brass cleaning and equipment used. I believe that the biggest improvement I found was primarily getting the technique of 'the nut pulling the trigger' tightened up to eliminate variations.

15 fps SD usually indicates a max deviation of between 45 to 50 fps. That is what factory ammo generally measures for me.

My best reloads have gotten me an SD of 5 to 7 fps, about 15 to 21 fps max deviations, and my reloads are kept to Bullet Base to Ogive of =/- 0.0005 difference across 25 reloads with a powder charge measured to 0.1 grains.

The variations in velocity, even using the most accurate reloading techniques are due to the variations that occur in the primer/powder ignition process. Primers fire, not always the same way, into a powder load that may or may not be touching the powder charge with the same amount of powder since powder density in the cartridge is impacted by the cartridge lying flat in the chamber. The powder burn rate generates pressure and it can vary based upon temperature. It is that pressure that pushes the bullet out of the neck and propels it down the barrel. Consider the variations that can occur in that process and you can see why there can be differences in bullet velocity when it exits the muzzle. That results in the measured velocities that are represented in the SD calculation.

Powder load for your .308

A load of 45 grains of Varget with a 165 TGK creates pressure that is 98% of Pmax. I have never had any rifle shoot accurately when the pressure gets that close to Pmax. I would suggest a load around 42.9 to 43.0 grs of Varget that would get you to about 85 to 86% of Pmax with bullets seated at the recommended OAL. I would suspect that the reduced recoil and the lower pressure will help with the group sizes and also improve the life of your primer pockets and the brass in general.

Some recommendations:

My data gathered from over 74,000 reloads over the last 18 years, shows that SD is not the big factor in accuracy. Neither is using pins in tumbling, and such, but I have found that my inability to consistently set up in the exact same position after each shot makes the difference in accuracy.

If you want to see the impact that you, as the shooter, make to your accuracy, measure the SD of 20 of your 5-round group sizes with the same load with your rifle. If it isn't 0.040 or less, you have a lot of accuracy improvement possible just by eliminating your 'shooter induced variations'. That will give you more improvement in accuracy than improving your SD from 15 to 7 fps.

About 5 years ago, I took about a year to improve my shooting technique, primarily by ensuring that I was in the same position each time I pulled that trigger. My group sizes are now 2/3rds of what they were.

All of the following data was gathered using the exact same front rest, a Sinclair F-class bipod, and a Protektor rear rest. All were shot at 100 yards at the same range.

My $320 bargain Savage 12 FV .223 1:9 twist, out of the box, averaged 0.341 for 86 groups with a group size SD of 0.090.

I changed to an Oryx chassis because the factory bargain stock didn't have any stiffening and would twist under recoil. With the new chassis, and with working on my technique, the average dropped to 0.273 for 1446 groups with a group size SD of 0.052.

I continually worked on getting set up consistent, and even with my occasional trigger jerk or loss of concentration. The last 4 months of shooting averaged 0.257 for 108 groups with a group size SD of 0.035.

I didn't change any reloading techniques, I tumbled my brass with pins, used 5 different powders, and 18 different bullets. With the new Oryx Chassis, and over 1446 groups there were some differences in accuracy with different bullets and powders, but they were actually not all that great, within 0.020 group size differences. Over several years, the changes in SD of my group sizes were mostly due to eliminating my 'shooter induced variations'.

I know we often try to resolve problems by blaming bullets, powder, reloading techniques, brass cleaning and equipment used. I believe that the biggest improvement I found was primarily getting the technique of 'the nut pulling the trigger' tightened up to eliminate variations.

Last edited:

searcher

Gold $$ Contributor

I can only go by what I have learned over 30+ years shooting over a chronograph and seeing the results on target. For a number of years, I spent three full days a week at the range shooting different loads all day, around 1,000 rounds per week on average- and literally hundreds of thousands of rounds. I have thousands of targets in boxes with recorded info written on them to draw my own conclusions. I can't tell you how many fantastic groups were shot with SD in the mid 20's and how terrible the same load was when shot in the low single-digits. I do agree that most groups were better, as you say, with huge SD improvements. Going from 20 to 5 will not always produce a better group. if you don't believe that, that is your prerogative. I trust what I have learned over those years due to the huge volume of recordkeeping. But I am only one person. Your results may differ....I think you're overstating that by a lot. Going from an SD of 20 to 5 will improve groups by a lot, even at 100 yds, assuming the shooter if proficient. Going from a 15 to 12 or an 8 to a 5, one isn't likely to see much difference. And as I mention, it true that the lowest SD isn't going to say which load works best. But one isn't going to have consistent tight groups with high SD's.

The only problem with SS pins is getting the inside to the necks too clean. . . if one considers that a problem. The problem in wet tumbling is the cases themselves banging against each other on the narrow case mouths, especially those that have been chamfered and deburred. And especially bad if they're banging together over a long period of time. Whenever I wet tumble (not part of my normal procedure), it's only for 20-30 minutes using very hot water with Dawn and some Lemi-Shine and they come out nice and clean with no big issue on peening the mouths. Of course, chamfering afterwards always takes care of any peening anyway.

Ccrider

Gold $$ Contributor

I have annealed both ways. They both work. You have to figure out how to do either consistently. Salt bath is easier to get consistent because you can regulate the temperature and are only adjusting the amount of time in the salt bath.I would like to understand why salt bath annealing wouldn't provide a more consistent temperature than flame annealing?

I think It helps if we can put some quantification on what a reduction might mean. A 165 SGK with a SD of 20 will have a ES (5xSD) of about 100fps at 2600fps. On a 100yd target that will equate to about 0.2" deviation in point of impact due to velocity ignoring any "node" effects so if the rifle and shooter is capable of 0.5 MOA then the improvement if the SD/ES became 0.0 would be about 0.45 MOA. So it may be hard to detect on a factory rifle AT THAT RANGE. Even a 0.25 MOA shooter and rifle will only an improvement to 0.15 MOA on a large number of groups. Obviously those number change with flight time/distance.I think you're overstating that by a lot. Going from an SD of 20 to 5 will improve groups by a lot, even at 100 yds, assuming the shooter if proficient. Going from a 15 to 12 or an 8 to a 5, one isn't likely to see much difference. And as I mention, it true that the lowest SD isn't going to say which load works best. But one isn't going to have consistent tight groups with high SD's.

Hmmm??? Actually, I think we agree more that we disagree.I can only go by what I have learned over 30+ years shooting over a chronograph and seeing the results on target. For a number of years, I spent three full days a week at the range shooting different loads all day, around 1,000 rounds per week on average- and literally hundreds of thousands of rounds. I have thousands of targets in boxes with recorded info written on them to draw my own conclusions. I can't tell you how many fantastic groups were shot with SD in the mid 20's and how terrible the same load was when shot in the low single-digits. I do agree that most groups were better, as you say, with huge SD improvements. Going from 20 to 5 will not always produce a better group. if you don't believe that, that is your prerogative. I trust what I have learned over those years due to the huge volume of recordkeeping. But I am only one person. Your results may differ....

Yeah, I do feel the math helps. Besides my own anecdotal evidence, I do consider that math in support for my view on SD's.I think It helps if we can put some quantification on what a reduction might mean. A 165 SGK with a SD of 20 will have a ES (5xSD) of about 100fps at 2600fps. On a 100yd target that will equate to about 0.2" deviation in point of impact due to velocity ignoring any "node" effects so if the rifle and shooter is capable of 0.5 MOA then the improvement if the SD/ES became 0.0 would be about 0.45 MOA. So it may be hard to detect on a factory rifle AT THAT RANGE. Even a 0.25 MOA shooter and rifle will only an improvement to 0.15 MOA on a large number of groups. Obviously those number change with flight time/distance.

Last edited:

I work as an RSO on a private range so we often interface with shooters more than on some public ranges so reloading is a frequent discussion. Invariably we will encounter shooters burning up up rounds chasing SD because someone says lower is better. It's one thing when they are working on a custom barreled bolt action rifles and a totally different issue when it's a factory Savage or Rugar American. Not that they are bad rifles but definitely different. And then there are the AR's! It hurt's when you see someone with a rifle shooting 1"-2" groups at 100yds and trying to blame it on a 25 SD....

Yeah, I do feel the math helps. Besides my own anecdotal evidence, I do consider that math in support for my view on SD's.

just my opinion, but i just don't like the idea of dealing with molten salt just to anneal. sounds like too much f'ing around. my EP 2.0 annealer that can adjust from 17hornet to 50bmg in seconds & is up an running / annealing within no time is just so easy to use. Once you've done it a few times with the glow method you'll realize just how quick and easy it is & most people over think it.I just find it harder to determine how much time it take to get the right amount of anneal. With flame annealing, how the neck glows tells me a lot about timing regardless of brass thickness.

64Rambler

Gold $$ Contributor

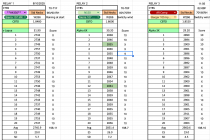

Gonna have to disagree that the CCI 450s are the issue. Here's the results of my last club match under less than ideal conditions. Raining and wind from every direction at the start and having to wipe the water off each case before firing. Relay 1 was virgin Lapua 6BR brass with a FF load using a messed up lot of H4350 with 2.8% N555. Relay 2 was my "usual" 6BRA load with N150 and 107 SMK - the low and high velocity shots (3 and 12) have identical elevation on target so getting some positive compensation there. Relay 3 was a test load with AR-Comp and 105 Hybrids. All 3 relays had an SD under 8 and all 3 shot with sorted CCI450s, 3 different powders, 2 different bullets and 3 different velocity ranges.

Attachments

Larger ES/SD can be a factor, but, mainly in long range work. As stated above, the differences at 100yd are small. The BR competitors will see the difference, but, I won't. At 600yd it does show up and at 1000yd it can be significant, usually showing up as vertical stringing.

Being on or off a node is much more important. I notice that nodes near max pressure (or a bit over ) are fairly narrow, so ES/SD will have more of an effect than if you are working at a lower/wider node.

) are fairly narrow, so ES/SD will have more of an effect than if you are working at a lower/wider node.

When you get the best of both, node and low ES/SD, you are in business. Some cartridges are 'easier' than others to get the low ES/SD numbers. The 6BR is one of those. Some are not, the .223 comes to mind.

Being on or off a node is much more important. I notice that nodes near max pressure (or a bit over

When you get the best of both, node and low ES/SD, you are in business. Some cartridges are 'easier' than others to get the low ES/SD numbers. The 6BR is one of those. Some are not, the .223 comes to mind.

How true. You actually reminded me of a video Keith Glascock did a few years ago. It discusses his view of "nodes" from his F-Class shooting days. He is an Engineer and puts a lot of experience and physics behind what he puts in his videos. I have found, in my limited experience that what he is saying applies to what most of use call nodes.Larger ES/SD can be a factor, but, mainly in long range work. As stated above, the differences at 100yd are small. The BR competitors will see the difference, but, I won't. At 600yd it does show up and at 1000yd it can be significant, usually showing up as vertical stringing.

Being on or off a node is much more important. I notice that nodes near max pressure (or a bit over) are fairly narrow, so ES/SD will have more of an effect than if you are working at a lower/wider node.

When you get the best of both, node and low ES/SD, you are in business. Some cartridges are 'easier' than others to get the low ES/SD numbers. The 6BR is one of those. Some are not, the .223 comes to mind.

JeTarget

Gold $$ Contributor

After reading the thread there’s something that I’ve noticed that may be missing, have you performed a ladder test yet? You stated that you’ve just started working up a load but I haven’t seen mention of any powder charges other than 45.0 varget. You may try stepping down in .1 increments down to 44.5 in 5 shot groups. It looks like you could be smack in the middle of 2 nodes.

While all of the above brass process can help with consistency powder charge would be my starting point with numbers that high if you are using decent brass.

While all of the above brass process can help with consistency powder charge would be my starting point with numbers that high if you are using decent brass.

ELR LVR

Silver $$ Contributor

Everything this guy saidSD won't make any difference in group sizes until you get beyond 600 yards. To shrink your groups check that your barrel is fully floated and that the action screws are tight (using a torque wrench is useful to find the settings the rifle likes and reproduce them). What are you using for rests? Are you using wind flags? Definitely read up on good benchrest technique. What sort of chronograph are you using? Models that use skyscreens can be finicky and small screen spacing can reduce accuracy; a radar chronograph is a good investment, and you can get get good deals on older used units. How much scope magnification do you have? You'll be able to hold closer with 20x than the typical 9x hunting scope.

You'll probably get smaller SDs with standard primers, and you should try several brands as a given powder will often prefer one over the others. Bullet jump will affect both group size and velocity/SD, so definitely investigate that (from hard jam to 0.050" jump). It's likely that 45 gr of Varget is a compressed load, and that can increase SD due to cracking powder granules. Trying a powder with 90-95% fill could work better. As your SD and group size improve, sorting brass and bullets will have some benefits.

Those are the ideas that I immediately thought of, but I'm sure you'll get additional ideas from others. There are may threads on each of these topics on this site, and doing searches will easily find them; each topic will produce pages of good advice.

Especially trying different powders AND trying different primers

If you're going to stick with SR, then Rem 7-1/2 have always been a Low SD primer for me

(WITH the right powder)

For LR - F-210 or BR-2's

Winchesters are usually the hottest primers

4895 and W-760 have been great powders for the 308 for me

That was narrowed down from about half a dozen other powders tried

-------------------

You may also try uniforming the depth of your primer pockets,

I did not see that mentioned in your post

Last edited:

ELR LVR

Silver $$ Contributor

^^^Those magnum primers are your problem. Try any non-magnum primer.... don't ask me how I know

I believe this is the main culprit too 90% of

all the other aspects may only improve things by 10%

Similar threads

- Replies

- 45

- Views

- 6,762

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.