Raythemanroe

Bullet Whisperer

Probably a troll, don't feed it!

Well, for a multitude of reasons, including wrong twist, length, weight, caliber. I want my next Howa to be 6mmBR, but they don't offer that, so the barrel has to be replaced.

Please don't automatically associate the TYPE of manufacture with the QUALITY of the product. It is entirely possible to make crappy (or excellent) button or cut-rifled barrels, just as much as it is to have variable quality in a hammer forged barrel, or any other product for that matter. Is HF technology so primitive that even at its best, it is simply not possible to produce a barrel that is superior to the "crude" barrel on stock guns? We will never know, since there is no one that I know of that has tried making a "high end" HF barrel. It could be said that no has tried to make the high end HF barrel because of some perceived acknowledment that HF barrels can never measure up to other technologies. But is it that, or possibly that HF barrels manufacture is suited to large deep-pocket companies who have little interest in niche markets, such as BR barrels? Not saying what is correct, just asking the question.

Sako makes the TRG-XX series of rifles, all of which use hammer forged barrels. These are not BR rifles, but few would say the barrel is "crude".

Actually, I am seeing more and more questioning of expensive custom actions vs tuned up factory actions. The custom actions sure look and feel nice though.

Phil

Well I guess I am screwed I shoot nothing but button rifle barrels.

Dug up some ol' Phil 3 posts.. I have been wondering if his hammer forged perfection has lit the world on fire..Well I guess I am screwed I shoot nothing but button rifle barrels.

That is what I read in this post if I am not running cut rifled barrel it pretty much says I won't be competitive.The heck you say! Why might THAT be?

That is what I read in this post if I am not running cut rifled barrel it pretty much says I won't be competitive.

I think if I remember correctly, been a few years since this was active but the OP thought hammer forged barrels could be superiorThat is what I read in this post if I am not running cut rifled barrel it pretty much says I won't be competitive.

That's funny I don't care who you are I am an old guy to.LOLUnderstood, Sir!

I know who you are. It seems I am having trouble with well-respected folks on the forum being un-aware that I'm just fooling around this evening.

Sorry, Stan. 'My bad.'

That's funny I don't care who you are I am an old guy to.LOL

Well I have a 1000yd match tommorow I will see how I fair with one of them old pushed button barrels I will keep you posted good or bad Thanks.An 'old guy' he says.

My backside, I says.

Well I have a 1000yd match tommorow I will see how I fair with one of them old pushed button barrels I will keep you posted good or bad Thanks.

Thats because a hammer forging machine is very expensive. The small custom barrelsmith have much cheaper cut rifling machines - most of them are Prat+Whitney and many many decades old or much cheaper button rifling machines.

Here in europe we use more hammer forged barrels because there are enough companys who offer them.

Well made there is no difference if a barrel blank is hammer forged, cut or buttoned but a hammer forged barrel blank can be made within much lower tolerances and so the custom gunsmith safe a lot of lapping and calibrating time.

The only big dissadvantage at hammer forging is the twist. It can`t be changed - it`s fixed by the hammer mandrel and this mandrel is very expensive. Thats a big benefit for cut and buttoned.

Well there's someone obviously affiliated with a company that uses hammer forged barrels

Hammer forged barrels will never be up to par with high quality button or cut rifled custom barrels...EVER. There's just no way that beating a piece of metal around a stick can make a barrel with benchrest accuracy.

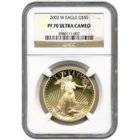

I appreciate our custom barrel industry more than anyone save their actual owners, but we should not forget that an item like this Cameo Gold Eagle, below, - far more intricate than a barrel’s rifling, is struck in a manner that most closely would mimic cold hammer forging. You could theoretically roll on the image like newspapers are printed or barrels are labeled, and that would resemble button rifling. Likewise you could scrape away everythg that is surplusage, like chiseling a sculpture, or a using a stock duplicator, and that method would resemble cut rifling. Which method would you suppose results in most perfect metallic impression/image?

I’m glad that hammer forging hasn’t overrun a cottage industry, but product inferiority is not the reason in my opinion. Endlessly differing barrel requests are the reason, along with high equipment costs, and the fact that they would shoot no better.

View attachment 1057031