I have some beautiful Peterson 6mm Creedmoor brass, should I FL size it?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FL Size new Peterson brass

- Thread starter Ironworker

- Start date

RegionRat

Gold $$ Contributor

You can, but since you asked...

If they chamber in your guns, then I would just make sure the necks are where you like them and go.

They are likely already at or below what your FL size die would do with the shoulder and body if they fit in the chamber as they arrived. You still need to put the neck tension where you want it and may find your chamfer isn't what you like either.

ETA: If this is a brand of brass you have never run before, now is the time to make a close inspection of all the virgin dimensions and stats to compare to your baseline. This is how you know what if anything your die would be doing to virgin or cycled brass.

If they chamber in your guns, then I would just make sure the necks are where you like them and go.

They are likely already at or below what your FL size die would do with the shoulder and body if they fit in the chamber as they arrived. You still need to put the neck tension where you want it and may find your chamfer isn't what you like either.

ETA: If this is a brand of brass you have never run before, now is the time to make a close inspection of all the virgin dimensions and stats to compare to your baseline. This is how you know what if anything your die would be doing to virgin or cycled brass.

No.I have some beautiful Peterson 6mm Creedmoor brass, should I FL size it?

NO.

NO

There's really no need to FL size it as it's best to fire form them before any of you're expectations might be realized. The one thing you might want to do is to simply run a mandrel through them to be sure the necks are round, though Peterson brass usually doesn't have the problem of the neck mouths being dented due to the way they're packaged.I have some beautiful Peterson 6mm Creedmoor brass, should I FL size it?

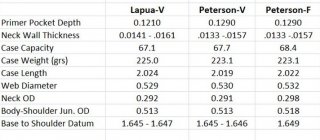

As RegionRat mentioned, if this is new brass to you, it'd be a good idea to take a bunch of measurements to compare them to what you're familiar with. I did this with some Peterson 6.5 PRC brass I acquired last year comparing not only virgin brass but also what they were after being fired):

Ned Ludd

Silver $$ Contributor

In most instances, the reason to full-length size virgin brass isn't because you want to size the case bodies, but because you want to size the case necks, and not everyone has a neck sizing setup. It is pretty easy to take some measurements to determine how consistent virgin brass neck diameter is straight out of the box, and whether it will provide the desired neck tension/interference fit. If it is not consistent, it is not too difficult to improve it and potentially markedly improve how well load will shoot in virgin brass. If the main goal is simply to fire-form the brass and it doesn't matter whether or not it shoots well, then it's probably not worth the effort. However, virgin brass can often be made to shoot very well indeed if doing so is of any interest to the reloader.

In my hands, the neck diameter of virgin brass can be all over the map, and that includes every brand of "quality" brass I've ever used. It's simply not very consistent straight out of the box. For that reason, I size virgin cases down first with a bushing die, then open the necks with a mandrel to achieve more consistent neck tension. Using a bushing die with the appropriate diameter bushing for the first step in this process will typically not move the case shoulder at all if it is properly set up. I generally try to select a bushing diameter that is approximately .001" smaller than I would use if it were to be the sole neck sizing step. That way, all of the necks will be sized down to some specified minimum diameter that is slightly smaller than the subsequent mandrel step will leave them. I then open the necks back up with a mandrel that is .0015" under bullet diameter, which typically yields very close to .002" neck tension.

The diameter of the bushing and mandrel selected can be adjusted for to generate pretty much any neck tension desired. The key to consistency is that the bushing needs to size the necks to a slightly smaller outside diameter than the mandrel will leave them so that the mandrel step actually does some work to open up all of the necks uniformly.

In my hands, the neck diameter of virgin brass can be all over the map, and that includes every brand of "quality" brass I've ever used. It's simply not very consistent straight out of the box. For that reason, I size virgin cases down first with a bushing die, then open the necks with a mandrel to achieve more consistent neck tension. Using a bushing die with the appropriate diameter bushing for the first step in this process will typically not move the case shoulder at all if it is properly set up. I generally try to select a bushing diameter that is approximately .001" smaller than I would use if it were to be the sole neck sizing step. That way, all of the necks will be sized down to some specified minimum diameter that is slightly smaller than the subsequent mandrel step will leave them. I then open the necks back up with a mandrel that is .0015" under bullet diameter, which typically yields very close to .002" neck tension.

The diameter of the bushing and mandrel selected can be adjusted for to generate pretty much any neck tension desired. The key to consistency is that the bushing needs to size the necks to a slightly smaller outside diameter than the mandrel will leave them so that the mandrel step actually does some work to open up all of the necks uniformly.

Last edited:

Nope, toss a handful in your gun and and see if the bolt closes which it will. Then use a expander mandrel to set the neck tension and load them up.I have some beautiful Peterson 6mm Creedmoor brass, should I FL size it?

Last edited:

Liven The Dream

Gold $$ Contributor

I do a complete Prep on my Brass . Why maybe Nuts ?

I like things in order . Then I just think I have done my job.

I like things in order . Then I just think I have done my job.

I do but with zero bump.

The reason is I like to uniform the necks and align them with the body of the case. The latter is probably not necessary if you have high quality cases. But I've had some virgin Remington and Winchester case that a few required this procedure, so I just do them all.

Also, I had one lot of Hornady cases that were over size. I had to FL size them to chamber in my rifle. Admittingly this is very rare and only happened once with me. This is not a knock on Hornady cases, I like them but in mass manufacturing, s*** happens.

However, this is the one effective purpose in which a neck sizing die can be put to use. Just neck size them to uniform the necks if you have high quality cases.

Whatever you do, you do not want to push the shoulder back on virgin cases unless the cases won't fit in your chamber.

The reason is I like to uniform the necks and align them with the body of the case. The latter is probably not necessary if you have high quality cases. But I've had some virgin Remington and Winchester case that a few required this procedure, so I just do them all.

Also, I had one lot of Hornady cases that were over size. I had to FL size them to chamber in my rifle. Admittingly this is very rare and only happened once with me. This is not a knock on Hornady cases, I like them but in mass manufacturing, s*** happens.

However, this is the one effective purpose in which a neck sizing die can be put to use. Just neck size them to uniform the necks if you have high quality cases.

Whatever you do, you do not want to push the shoulder back on virgin cases unless the cases won't fit in your chamber.

I run an expander .002 under bullet diameter in the necks, chamfer & deburr, and load on any new brass.

After you run through cases and cases of different calibers you will find the one box that might not chamber cleanly, but the necks are almost ways too tight and need a mandrel.

Similar threads

- Replies

- 11

- Views

- 677

- Replies

- 40

- Views

- 1,998

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.