It appears like I might have to have to make an adjustment to my annealing process??? ¯\_(ツ)_/¯

I recently bought a Webster Hardness Tester to test my various brass for the harness of their necks and to see how the results of my annealing compares to the likes of Lapua virgin brass. It's not a tool that's going to give you any kind of true Vickers harness result, but it can be used somewhat like a comparator.

First, upon getting the tool, I took a reading on the test strips to see if the tool gave me the reading I was supposed to get, and it did. Next, I tested some different virgin Lapua and Peterson brass that I've been hanging onto. The readings for my virgin Lapua brass were consistently at ~14.5 and the Petersons were just a hair over 15 (the higher the number, the harder the brass). Now I wanted to see what numbers I get with the cases I've annealed. I took readings from various various Lapua brass that has been fired a number of times and annealed after every firing and consistently got a reading @17; not as soft as I thought I was going to see. Then measuring my fired and annealed Peterson brass and my Federal brass and they too measured @17 (was expecting Federal brass to be different). Apparently, my use of the "glow method" was not getting my necks as "annealed" as I thought.

When I use the "glow method", in a darkened room I look for the necks to begin to glow and have the cases drop out of the flame at that moment. This has been working just fine in getting a good and consistent seating. But apparently, I'm going to have to let the necks stay in the flame a little longer after they start to glow if I want to get the hardness to the same level as Lapua virgin brass.

This is something I'll have to be testing for a while to see what the results might indicate.

Reaching back in my stash, I pulled a box of Lapua that I had just fired and annealed twice, before I really started using the "glow method". The method I used with them when annealing was to simply wait for that orangish-yellow flame to appear and then let the case drop when that happened. In testing the hardness of these, the reading was @ 18; not a surprise given my glow method was giving me something a little softer as expected.

I've got a small tub of test brass (mostly Federal range brass that I've picked up) that I use when setting up the timing for annealing and I know some of those were well over heated. Sure enough, I was getting some readings from 11 to 12 and a few at 14. I didn't expect any consistency since adjustments were being made with them to get the timing where I wanted it.

I'll report back after making some adjustments to the timing of my annealing process about what I've observed in terms of the harness test as well as what I might see when seating and the shooting results.

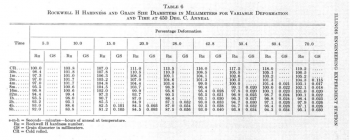

BTW: According to the manual that came with the tool, a reading of 15 is ~99 on the Vickers HV scale and a reading of 18 is ~ 131.

View attachment 1605761