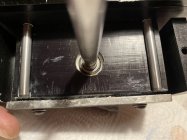

In this photo you posted...is that bearing loose in the plate? Or is the bearing sloppy? It should feel nice and smooth with no play in the bearing. Yours does look dry and dusty.

Your photo is only showing the shooters side of the plate (I think). Do you have a photo of the back side (the side of the plate that faces the target)? The epoxy is only on the back side, you won't see any on the area that faces the shooter.

Can you gently push on the shooters end of the joystick to see if the bearing moves out?

This needs the entire rear main bearing with shaft and inner ('up/down') plate to be removed first. That main bearing should be able to move in and out slightly when in use. Can you tap yours out all the way (towards the shooter) direction and remove the whole assembly from the main frame? Would like to see a photo of what's going on with the bearing and the inner plate.

Once out you don't need to hammer it! A good push will show if the inner bearing is loose in the plate (the 'up/down' plate).

If it is, then yes...push it right out, clean the outer race edges and the machined hole the bearing fits in.

Then a new epoxy or Loctite job. Not too much...just the outer edges where they contact the wall of the hole.

You will see in the 2nd photo where my bearing shaft also shows epoxy around the shaft where it passes through the bearing.

The red arrow points to where you need to place a 'thin' film of epoxy all the way around that surface. Don't go putting on too much and jamming up the inner bearing race.

Your 2nd photo (above) shows the main support bearing that fits in the main frame of the unit. Looks like someone has thumped that out with a metal punch. That may have messed up your main support bearing? Use a socket of correct size to fit the outer race of that bearing if you need to tap it out. It's driven out by knocking it back towards the shooter's side. Then driven in from the shooter's side towards the target area when fitting it back.

That main bearing may be tight from lack of maintenance, but when assembled it should be a nice sliding fit. Mine just pushes together with a wee bit of a push...no hammer needed!