You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY FOAM CUTTER

- Thread starter rdb8847

- Start date

I was told to freeze the foam first before using the eknife.

coldboreshot

Silver $$ Contributor

You can buy hot wire foam cutters or find plans for making one online. I've not tried one yet but have considered it for some time. May have to give it a try.

I think he's talking about polyethylene foam, not polystyrene foam. All I've ever seen used is like an electric carving knife with the reciprocating blades. It's a specialized tool.

I've made my own for cutting styrofoam wings for R/C airplanes with nichrome wire using a battery charger for power.

I've made my own for cutting styrofoam wings for R/C airplanes with nichrome wire using a battery charger for power.

The reciprocating blades of an electric carving knife have always been my “go to” as I get a smooth cut even for curves or into corners. Just go carefully and keep knife vertical and not force the blades through the foam.I think he's talking about polyethylene foam, not polystyrene foam. All I've ever seen used is like an electric carving knife with the reciprocating blades. It's a specialized tool.

I've made my own for cutting styrofoam wings for R/C airplanes with nichrome wire using a battery charger for power.

I use a white art pen to mark out the shape I plan to cut and if you are cutting the “Pluck” type foam {I hate it and have replaced it in several cases but it took a long time to find a specialist “Rubber” store that had “Gun Case” rated foam = $$} Not all foam is the same and some of the lesser stuff breaks down over time into crumbly bits…

Half cut small blocks can be glued in with contact adhesive to keep then in place and not fold down when putting your gun into and out of the case.

For those advocating or thinking about using a Hot Wire I would advise that you wear breathing protection as the fumes are toxic.. A hot wire is really only good for exterior cuts and would be a pain to dissemble and put back through for an interior cut.

The reciprocating knife will easily make a plunge cut and away you go and can be had from Wally Mart or Amazon for $20-40 depending on quality… Mine cost me about $28 for WM.. No shipping cost.

Fast14riot

Gold $$ Contributor

An electric fillet knife works better than an electric carving knife. Fillet knives have plain edges instead of serrated. Keep it very sharp.

I agree, just did not see any for sale at the time I bought the carving knife or I would have gone for one of those… Perhaps next time as they are cheap enough…An electric fillet knife works better than an electric carving knife. Fillet knives have plain edges instead of serrated. Keep it very sharp.

They will make cutting curves and corners even easier.

BuffaloBill

Silver $$ Contributor

Here’s one I made maybe 10yrs ago. Used 28ga nichrome wire, an old laptop power supply, and a FET- based PWM controller (eBay). The rubber hose was an easy way to extend the PWM controller’s potentiometer shaft through the frame. I adjust this pot for a moderate glow in the wire.

The templates made from paneling work well as a guide to cut reasonably straight pockets. I just lay them on the foam, passing the wire through the opening, etc. If you load that case full of pistols it get’s plenty heavy to carry around…..

The piece of thin-walled tubing laying on the foam was used in a drill press to make the magazine cutouts. I sharpened one end of the tube and used another piece of paneling with three overlapping holes as a template (that didn’t get in the picture).

The templates made from paneling work well as a guide to cut reasonably straight pockets. I just lay them on the foam, passing the wire through the opening, etc. If you load that case full of pistols it get’s plenty heavy to carry around…..

The piece of thin-walled tubing laying on the foam was used in a drill press to make the magazine cutouts. I sharpened one end of the tube and used another piece of paneling with three overlapping holes as a template (that didn’t get in the picture).

rdb8847

Gold $$ Contributor

I like this set up. Not sure I know what a FET based PWM is but Im going to look it upHere’s one I made maybe 10yrs ago. Used 28ga nichrome wire, an old laptop power supply, and a FET- based PWM controller (eBay). The rubber hose was an easy way to extend the PWM controller’s potentiometer shaft through the frame. I adjust this pot for a moderate glow in the wire.

The templates made from paneling work well as a guide to cut reasonably straight pockets. I just lay them on the foam, passing the wire through the opening, etc. If you load that case full of pistols it get’s plenty heavy to carry around…..

The piece of thin-walled tubing laying on the foam was used in a drill press to make the magazine cutouts. I sharpened one end of the tube and used another piece of paneling with three overlapping holes as a template (that didn’t get in the picture).

View attachment 1687479View attachment 1687480View attachment 1687481View attachment 1687482

BuffaloBill

Silver $$ Contributor

It’s a simple circuit that switches a load on&off at a given rate, having an adjustable duty cycle to effectively adjust the average current through the wire. Here’ a link to one similar to the one I used:I like this set up. Not sure I know what a FET based PWM is but Im going to look it up

10-50V 40A DC Motor Speed Control PWM HHO RC Controller 12V 24V 48V 2000W MAX | eBay

Rated current: 40A Maximum output current. - PWM Regulation range:5-100%. - All kinds of dc lamp was dimming, all kinds of dc heater adjust the temperature. - Great for all kinds of general-purpose and have a DC motor speed with brush.

www.ebay.com

Fast14riot

Gold $$ Contributor

Here’s one I made maybe 10yrs ago. Used 28ga nichrome wire, an old laptop power supply, and a FET- based PWM controller (eBay). The rubber hose was an easy way to extend the PWM controller’s potentiometer shaft through the frame. I adjust this pot for a moderate glow in the wire.

The templates made from paneling work well as a guide to cut reasonably straight pockets. I just lay them on the foam, passing the wire through the opening, etc. If you load that case full of pistols it get’s plenty heavy to carry around…..

The piece of thin-walled tubing laying on the foam was used in a drill press to make the magazine cutouts. I sharpened one end of the tube and used another piece of paneling with three overlapping holes as a template (that didn’t get in the picture).

View attachment 1687479View attachment 1687480View attachment 1687481View attachment 1687482

Did you go for a Jfet or Mosfet on your controller?

BuffaloBill

Silver $$ Contributor

I’m not sure Jfets are really a thing anymore. I purchased the controller. It uses mosfets.Did you go for a Jfet or Mosfet on your controller?

Fast14riot

Gold $$ Contributor

I'm an audio guy, I like Jfets, lol! Mosfets are a bit easier to plug into circuits than Jfets, but Jfets are more stable. Though I suppose a PWM controller for a hot wire doesn't really matter in the grand scheme of things, lol!I’m not sure Jfets are really a thing anymore. I purchased the controller. It uses mosfets.

Bottom Fodder

Silver $$ Contributor

I was a SCR guy backing in my working days but they’re A little over kill for this project lol. Carry on with this. It’s nap time for meI'm an audio guy, I like Jfets, lol! Mosfets are a bit easier to plug into circuits than Jfets, but Jfets are more stable. Though I suppose a PWM controller for a hot wire doesn't really matter in the grand scheme of things, lol!

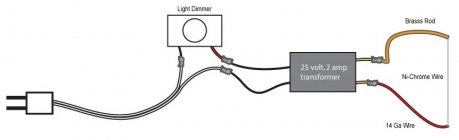

Don't over do it. A rotary dimmer light switch (push on-off) and a down converter is all you need. Plus some nichrome wire. Build a table (bigger is better so the foam sheets can slide easily) and arm like Buffalobill and you're done. There's a bit of technique involved in the actual cutting to avoid flex of the wire by the foam but that's about it. I highly recommend making a stencil (as Buffalobill did) in stiff cardboard for each part (rather than marking the foam directly). Pin these in place and use the stencil as a guide for the hot wire.

Last edited:

There were some good threads going through the set up and process on AR15.com

www.ar15.com

www.ar15.com

Cutting Gun Case Foam (lots of photos) > Build It Yourself > AR15.COM

Firearm Discussion and Resources from AR-15, AK-47, Handguns and more! Buy, Sell, and Trade your Firearms and Gear.

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.