My wife and I are in the process of moving. The plan was to take this upcoming week to leisurely start packing. I had reserved a truck with a lift gate (for the mill and lathe) for the first week of Feb.

Since my lathe and mill are going to be down for a while I chambered three barrels for my new BAT M heavy gun about three weeks ago. I had also ordered two stocks about a month before we decided to move. One was an @Alex Wheeler LRB, the other was a Richards Microfit. Both were flat tops.

The Richards Microfit came a couple days ago while we were in N. Idaho. I had a job interview, and we nailed down an apartment and storage unit until we can get into a house.

I thought great, I have time to get the Richards inletted and bedded and then I'll be able to compete with my heavy gun. While we were on the trip the appraisal come through and the buyers want to move up closing. So I rescheduled the moving truck to next week.

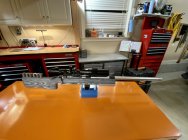

I had still hoped to get the Richards Microfit inletted and bedded. I gave myself Friday evening and Saturday to get it done. I got the rudder installed Friday, and was making steady progress on the inletting today, then the Z-Axis feed of my mill broke. I suspect it's an easy fix but I cannot even use the manual crank right now. I can directly spin the screw in the column so I think I can still get the inlet compete.

I am taking a little break, then I hope to finish. I still need to mill out the trigger area and the trigger guard. The rest (bolt handle, feed and ejection ports) I can do with a Dremel later.

The apartment does have a garage but no 220. It may well be a year before we get into a house and I am able to run my mill and lathe again. With the original closing I could have finished the Richards and even the LRB--Alex called me today and told me it had come in.

As it is I hope to have my heavy gun ready for matches in March and I would like to make the NBRSA Nationals in April. Right

now it's looking iffy, and the LRB will sit for a while. That said, It was good to practice on the $200 stock since it was my first time doing a full inlet on a flat top.

The big task of packing and moving starts tomorrow.....

Since my lathe and mill are going to be down for a while I chambered three barrels for my new BAT M heavy gun about three weeks ago. I had also ordered two stocks about a month before we decided to move. One was an @Alex Wheeler LRB, the other was a Richards Microfit. Both were flat tops.

The Richards Microfit came a couple days ago while we were in N. Idaho. I had a job interview, and we nailed down an apartment and storage unit until we can get into a house.

I thought great, I have time to get the Richards inletted and bedded and then I'll be able to compete with my heavy gun. While we were on the trip the appraisal come through and the buyers want to move up closing. So I rescheduled the moving truck to next week.

I had still hoped to get the Richards Microfit inletted and bedded. I gave myself Friday evening and Saturday to get it done. I got the rudder installed Friday, and was making steady progress on the inletting today, then the Z-Axis feed of my mill broke. I suspect it's an easy fix but I cannot even use the manual crank right now. I can directly spin the screw in the column so I think I can still get the inlet compete.

I am taking a little break, then I hope to finish. I still need to mill out the trigger area and the trigger guard. The rest (bolt handle, feed and ejection ports) I can do with a Dremel later.

The apartment does have a garage but no 220. It may well be a year before we get into a house and I am able to run my mill and lathe again. With the original closing I could have finished the Richards and even the LRB--Alex called me today and told me it had come in.

As it is I hope to have my heavy gun ready for matches in March and I would like to make the NBRSA Nationals in April. Right

now it's looking iffy, and the LRB will sit for a while. That said, It was good to practice on the $200 stock since it was my first time doing a full inlet on a flat top.

The big task of packing and moving starts tomorrow.....