You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crap components to good loads

- Thread starter Wolfdog91

- Start date

Bottom Fodder

Silver $$ Contributor

If it feels good do it, no I would not use use range pick up brass at a world championship but I might use Sierra bullets along with some other crap

This is a plinking discussion, varmint shooting requires a significant dedication to maintaining component quality control..So, I have a weird question that I've been mulling over for a while now. And I'm not a competition shooter or super advanced reloader by any means lol , I'm just a guy who likes to experiment and tinker and reloading a a good medium for that for me .

Anyhow in watching and listing to guys like Eric Cortina , Jack Neary , FClass John , Bryan Litz and the like , the whole deal of making reloading " easy" by buying quality components is just common sense. Berger+ laupa+ Vitavoirri powder = easy reloading. Everything is made to such high quality and standards they just plain work.Makes perfect sense .

Currently trying to do that myself instead of buy the cheapest whatever I can like I used to. Time and cost has just made it cheaper for me to buy stuff that works instead of experiment (which I enjoy a bit more if I can do it cheaply)

But I'm just curious though have any of y'all ,just for the sake of doing it , ever went and got the cheapest brass ,bullets powder ect and said " I'm going to make a decent load out of this"? And if so what did you learn ? Other then it's easier to just get better stuff lol. Like was their anything you learned from messing with junk and making it work that helped you with better quality stuff ? Like idk did you have to be more careful with brass prep or did you find with crap powder one type of prime worked better then another and so on ?

I ask because with a lot of stuff I've done like welding I started out or just had to make do with junk for a long time and doing that made me learn a lot of stuff, then when I got a hold of good quality gear it was like I was running circles around people ( welding with a little 110 flux core machine for two years making it work then going to collage for weling and getting my hands on an actual nice machine being an example). Figured someone may have had the same experience with reloading.

Anyway sorry if this is kinda a dumb thing to ask ,just (as usual) curious as hell

Poor bullet quality will cause you the most problems.

Shooting mixed lots of brass the next.

Mixing primer brands the next. Just my opinion.

Gargoyle

Finder Outer

People have tried to give me mixed headstamp brass. I don't take it unless it's my headstamp. Composition of the brass between brass sizes up different in the dies, different case capacities, etc. Lot's of folks don't get that.This is a plinking discussion, varmint shooting requires a significant dedication to maintaining component quality control..

Poor bullet quality will cause you the most problems.

Shooting mixed lots of brass the next.

Mixing primer brands the next. Just my opinion.

Depends on application... crap or inexpensive components can shoot well...not for serious competition, but field shooting, hunting, or plinking fun.

I agree. For many users and applications, ES and SD values are unimportant and all they care about is whether they can hit reasonably close to the aiming mark at short distances.

Years ago, I got interested in this when shooting pistol cartridge leverguns in a series of quarry ranges, and a police armed team was practicing next door with SIG 223 semi-auto military type rifles. My companion on the 50 metre range disappeared after the racket in the adjacent 100 yard facility ended and reappeared with a large bag full of fired 223 cases. He knew the officer in charge and this was a regular occurrence it seemed.

I had a look at them and was appalled. I wouldn't have put these through any rifle I owned. They were battered and some had really deep ejector peg impressions on the case-heads and rims, I wondered if the hammering they'd taken would have knocked case-heads out of true with the bore axis. Anyway, the guy says to me that his brother is a gamekeeper on a large sporting estate in the north of Scotland and he's always short of 223 brass for carrying out his endless task of fox and other predator control, ejected cases usually lost in the heather or grass. "He rejects the worst cases, but the rest shoot just fine - 150 yards is a long shot up there." he says.

Years on and the Marketing Director of a major UK distributor presents me with a couple of bubble packs of American 'Top Brass' cleaned, sized and primer pocket decrimped military brass for review, one each of 50-ct '223 Rem' and '308 Win' cases (5.56 and 7.62mm of course). They sat on my shelf for years until I started on a major exercise using a 223 F-Class rifle for testing H. VarGet and H4895 alternatives, these powders no longer available to us thanks to health & safety regulations. These used Lapua cases, all starting out new and most batched.

I decided to use the 'Top Brass' cases with a load from the powder tests in a standalone minor secondary test using the bullet, primer, and a powder and charge weight from the main (Lapua case) series. The 223 Top Brass examples were overwhelmingly LCs with a variety of headstamp years, but included 5 x TAA (Taiwan - a new one to me); 1 x WCC; 1 x IVI (Canadian). I should say that although I know LC 5.56 brass is widely used in the US even by some match shooters, it is a rarity in the UK and we have no experience of using it. There was a near 10gn weight difference between typical LC and the heaviest of the 'minority' group and 0.8gn water capacity variation once fireformed.

The brass was used out of the pack apart from a slight shoulder-bump to suit my very short 223 chamber and a case-mouth rechamfer with a carbide 'VLD' profile tool. 30 odd were loaded up with my test load - Russian PMC SRM primers and batched 77gn SMKs loaded to a non-SAAMI COAL to suit my long-throat chamber as used in the powder tests, the powder charge 24.6gn Lovex S0-62 (Shooters World 'Precision' in the US), largely because that powder had been the subject of my most recent previous VarGet-alternative test and also because I had just enough left in the tin to do a couple of small exercises only.

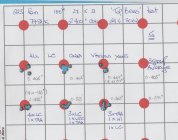

Of the 30 fired as groups, half were all-LC; the other half as big a mix as the supply allowed. I forgot the chronograph on the day, but no matter as it was 100-yard groups I was interested in. Using Lapua brass, the same combination had averaged a shade over 0.3-inches over the final four S0-62 groups with the highest charges including that used in the 'Top Brass' brass test (24.0-24.9gn). These were 4-round groups and the 'Top Brass' groups were now three each of five shots, plus some same-load 'foulers' having been fired beforehand to condition the bore.

Shot in a full F / BR set-up off the bench using a heavy front-rest and three-inch width forend, the three by LC groups were remarkably consistent at 0.401-0.403" C-to-C. The mixed brass trio more variable with 0.325-0.425". On the three-group averages, the mixed brass group 'won' out at 0.371" v the all-LCs' 0.403".

Yes, I know - redo the tests and results would most likely be reversed and it would take a 10 (or more) -series run to meet Bryan Litz's findings on group size variabilities as shown in Modern Advancements in Long Range Shooting Vol 3. Nevertheless, I felt this collection would have worked just fine mixed up as they came for the aforementioned Scottish gamekeeper's 50-150 yard predator shots.

Naturally, I wouldn't use this brass, segregated or not, in an F-Class match, but it's back to distance, application, and for many shooters cost - horses for courses as the old folk-saying has it.

Last edited:

Pick up as many 223 cases as you can find at the ranges around where you live. Sort the head stamps and get a bunch of lake city. Size and trim to length. weigh and find 50 that are close to the same weight. trim flash holes. Or just buy Peterson, ADG or Lapua. a lot of work and time but you will learn along the way. Look at every thing that it takes to make aa hole in the target, brass, powder, bullet, primer, dies, rifle, rest, shooter, scope, ect, ect pick out the one thing that is causing the most spread in the group. Ask a respected shooter to tell you what he/she thinks is the weakest link in your process. Post the list here and ask others to offer an opinion. Fix the biggest problem first. i have found that i always pick the wrong thing to fix first. changing the seating depth is not going to help when the scope is moving 3 moa with every shot.

DShortt

Gold $$ Contributor

I don't understand your last sentence. What do you mean by 'the scope is moving 3 MOA with every shot.'? Is this an exaggeration?Pick up as many 223 cases as you can find at the ranges around where you live. Sort the head stamps and get a bunch of lake city. Size and trim to length. weigh and find 50 that are close to the same weight. trim flash holes. Or just buy Peterson, ADG or Lapua. a lot of work and time but you will learn along the way. Look at every thing that it takes to make aa hole in the target, brass, powder, bullet, primer, dies, rifle, rest, shooter, scope, ect, ect pick out the one thing that is causing the most spread in the group. Ask a respected shooter to tell you what he/she thinks is the weakest link in your process. Post the list here and ask others to offer an opinion. Fix the biggest problem first. i have found that i always pick the wrong thing to fix first. changing the seating depth is not going to help when the scope is moving 3 moa with every shot.

meaning have a good mount that is torqued properly so that the scope is a nonissue. Could also mean having a quality scope that will track and maintain zero.I don't understand your last sentence. What do you mean by 'the scope is moving 3 MOA with every shot.'? Is this an exaggeration?

DShortt

Gold $$ Contributor

I don't think torque on screws will amount to 3 MOA of disparity nor would scope tracking. If the mounting screws are loose/no torque or the scope won't hold a setting then yes, I can see that. However both of these conditions seem to be out of the context of this thread which is why I asked for clarification from the member who made the statement.meaning have a good mount that is torqued properly so that the scope is a nonissue. Could also mean having a quality scope that will track and maintain zero.

Having loose scope caps allowing the scope to move would more than certainly allow for 3 moa of disparity, as would a scope that has internals that are messed up or not made well enough to maintain zero. A scope only has to move a few thousandths of an inch for the downrange result to be substantially different.I don't think torque on screws will amount to 3 MOA of disparity nor would scope tracking. If the mounting screws are loose/no torque or the scope won't hold a setting then yes, I can see that. However both of these conditions seem to be out of the context of this thread which is why I asked for clarification from the member who made the statement.

DShortt

Gold $$ Contributor

I'm not trying to argue either of those points. Loose hardware in multiple places can cause such a problem but loose and improperly torqued mean two different things to me. Perhaps we are simply differing over semantics and if so then I apologize for the confusion. I would still like to hear what the member who made the statement meant and I thank you for your input.Having loose scope caps allowing the scope to move would more than certainly allow for 3 moa of disparity, as would a scope that has internals that are messed up or not made well enough to maintain zero. A scope only has to move a few thousandths of an inch for the downrange result to be substantially different.

I worked on a rifle for a year trying to get it to shoot. It was a 223 Remington on a 700 short action Billy Stevens threaded and chambered. It would shoot 2 or 3 shots in a bug hole them 2 all over the palce A member here that passed away maned Octopus was an engineer a Perry Oceanographics, he keep telling me it isn't your load, no load shoots that bad and that good in the same 5 shot sequence. I tried everything. one day at the range he pulls out a Hood scope checker. I took the night force i knew to be good and the scope on the 223 and put them side by side on the hood scope checker and on the third shot they were no longer pointing at the same spot. now you are right they were not three MOA different, but they were over one MOA apart. when i started shooting this gun, i pulled a brand new scope out of the box, and it was trash from day one. What i learned was even the cheapest crap ammo shoots better out of a custom barrel than i was getting. So think about it what makes a gun shoot that bad ? A scope, a barrel, for sure but maybe other things, but not seating depth or a different primer. Fix the biggest problem first!

Gargoyle

Finder Outer

This is me:

I've been loading on a Lee 4 hole turret press for 22yrs. I use RCBS and Redding dies. Usual dies, no competition anything. I mainly use Prvi Partizan brass because it's really good brass, and everyone on the internet thinks it sucks and won't lower themselves to use it, so more for me always. I use Lapua brass I bought 15yrs ago and I can't tell any accuracy difference between Lapua and Prvi. RCBS 1500 chargemaster dispenser. I pluck out any overages with my fingers.

I sold off a concentricity gauge 15yrs ago after I ran a blind test of runout batches measuring .001" vs .008" and couldn't tell a difference in accuracy between the runout batches. Neck turning? Never heard of her. I find my bullet jump/distance to lands by gravity method. I've found .001" to .120" jump to print 1/8-1/4 MOA depending on the bullet. I anneal my own brass via cordless drill, socket extension, butane torch method. I trim my brass via cordless drill and Lee trimmer method.

I FL size everything and bump the shoulder .002" like Erik Cortina recommends.

I clean my barrels using Hoppes foaming bore cleaner, Hoppes Black copper remover, Flitz, and bronze brushes. I check the progress with a bore scope.

I shoot Sierra and Hornady bullets for the range guns, and Hammer bullets for the hunting guns. I don't own a gun that doesn't print 1/2 MOA at 100yds. I have evidence of 1 mile 1/4-1/2 MOA groups at the mile. MOA is my avatar group.

When I can't print bullets like I do I will change things up. Till then, I am doing a lot of things right, my targets tell the tale, and I read past a ton of subjects on here that so many get wrapped around the axle about and spend my time fretting over other stuff in life.

Yup.

I've been loading on a Lee 4 hole turret press for 22yrs. I use RCBS and Redding dies. Usual dies, no competition anything. I mainly use Prvi Partizan brass because it's really good brass, and everyone on the internet thinks it sucks and won't lower themselves to use it, so more for me always. I use Lapua brass I bought 15yrs ago and I can't tell any accuracy difference between Lapua and Prvi. RCBS 1500 chargemaster dispenser. I pluck out any overages with my fingers.

I sold off a concentricity gauge 15yrs ago after I ran a blind test of runout batches measuring .001" vs .008" and couldn't tell a difference in accuracy between the runout batches. Neck turning? Never heard of her. I find my bullet jump/distance to lands by gravity method. I've found .001" to .120" jump to print 1/8-1/4 MOA depending on the bullet. I anneal my own brass via cordless drill, socket extension, butane torch method. I trim my brass via cordless drill and Lee trimmer method.

I FL size everything and bump the shoulder .002" like Erik Cortina recommends.

I clean my barrels using Hoppes foaming bore cleaner, Hoppes Black copper remover, Flitz, and bronze brushes. I check the progress with a bore scope.

I shoot Sierra and Hornady bullets for the range guns, and Hammer bullets for the hunting guns. I don't own a gun that doesn't print 1/2 MOA at 100yds. I have evidence of 1 mile 1/4-1/2 MOA groups at the mile. MOA is my avatar group.

When I can't print bullets like I do I will change things up. Till then, I am doing a lot of things right, my targets tell the tale, and I read past a ton of subjects on here that so many get wrapped around the axle about and spend my time fretting over other stuff in life.

Yup.

I learned how to neck turn on Winchester brass, as well as all of the other case prep methods, pillar and epoxy bedded cheap rifles, used inexpensive scopes, and managed to get all but 2 of those guns to shoot. I learned a lot from them about how to test and verify a load and components, and I also learned that junk barrels, scopes, and bullets cost too much even if they're free. You can't make chicken soup outta chicken sh*t.

DShortt

Gold $$ Contributor

Thanks for clarifying.I worked on a rifle for a year trying to get it to shoot. It was a 223 Remington on a 700 short action Billy Stevens threaded and chambered. It would shoot 2 or 3 shots in a bug hole them 2 all over the palce A member here that passed away maned Octopus was an engineer a Perry Oceanographics, he keep telling me it isn't your load, no load shoots that bad and that good in the same 5 shot sequence. I tried everything. one day at the range he pulls out a Hood scope checker. I took the night force i knew to be good and the scope on the 223 and put them side by side on the hood scope checker and on the third shot they were no longer pointing at the same spot. now you are right they were not three MOA different, but they were over one MOA apart. when i started shooting this gun, i pulled a brand new scope out of the box, and it was trash from day one. What i learned was even the cheapest crap ammo shoots better out of a custom barrel than i was getting. So think about it what makes a gun shoot that bad ? A scope, a barrel, for sure but maybe other things, but not seating depth or a different primer. Fix the biggest problem first!

Ran Into a group of old timers at a range decades ago. They were having a summer long contest to see who could shoot the cheapest 5 shot group at 100 yards under 1 moa. They tried piles of cheap bullets and cheap powder. They also drank gallons of coffee as I remember. They definitely learned a few things. Were they nationally ranked F class shooters...... no. They didn't even have a podcast!

Mixing brass can produce interesting results not all good. I did however find 1 lot of once fired Malaysian military 5.56, (I know because I was there when the guy fired them) they allowed me to get 1 1/2 grain of powder in my 223 load which made a difference. I bought 1,000 for $5, those days are gone. I neck size and after 25 years I still have 925 of them. The load print 1 1/16" at 300 a great little chuck load.People have tried to give me mixed headstamp brass. I don't take it unless it's my headstamp. Composition of the brass between brass sizes up different in the dies, different case capacities, etc. Lot's of folks don't get that.

Pick up brass can be useful, (I doubt for competition) I sat beside a guy who ruined a brand new 300 Winchester magnum buy shooting 80 rounds through it at one sitting too fast. All one lot of the same ammo, I made 358 Norma out of them.

In the past ARs were not known to be even close as accurate as most bolt action rifles. So when a friend and i loaded for them we took a bucket of range brass, and full length sized trimmed to min and loaded 69 grain SMK with Winchester 748. i had long ago bought a 24 inch heavy barreled AR varmint rifle from him and he had a Colt Hbar they both shot pretty good with our mixed head stamped mismatched ammo. So, we are having a shoot of for Loxahatchee bragging rights and I see him going through his bag of brass looking for 10 rounds for the shoot off. Not sure of whats going on, I finally asked him what was up. Well is was digging around to find 10 with the same headstamp just to kick your but. Even with crap components he found a way to get the edge. Long story short there are lots of tricks that can help but the good stuff is a sure shot.

Similar threads

- Replies

- 4

- Views

- 403

- Replies

- 24

- Views

- 868

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.