- Home

- Forums

- Q&A: Gear, Gun Projects, and Gunsmithing

- Gun Project Questions & Gunsmithing

- Advanced Gunsmithing & Engineering

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

chambering and polishing

- Thread starter robbor

- Start date

LVLAaron

Gold $$ Contributor

There's a short book to be written about the couple of "famous" people who have been banned or left the forum.CS was excommunicated long ago.

Shucks.There's a short book to be written about the couple of "famous" people who have been banned or left the forum.

They're usually the most entertaining (as long as they're not aimed your direction), until they go and cross "THE LINE".

necro post lol!I think so

luckyshot52

Silver $$ Contributor

Polishing with 240 does not equate to polished!Cat Shooter, It is pretty simple. A polished surface has more surface area to grip with. Also the 50,000-60,000PSI explosion will fill the chamber from the shoulder to the bolt face. After the case is formed it will fill the chamber fully and a polished case will lessen the load on the bolt lugs. I think we are arguing about different things. I don't believe that I stated that the case would not touch the boltface. I did not state that you don't have pretty cases.

I stated that a polished case would grip the chamber walls. Have you heard of Dave Tooley? He has forgotton more about shooting and smithing than most of us on the forum have known. If you like, I will do a search and show you he "polishes" his chambers with 240 sandpaper.

Butch

Lucky Shooter

Gold $$ Contributor

I was told by a very good rifle guy that he polished chambers

only for appearance and customer demand.

His opinion was that the finish from a good reamer was good enough

and that further polishing never improved accuracy.

Just another opinion from a fine machinist.

A. Weldy

only for appearance and customer demand.

His opinion was that the finish from a good reamer was good enough

and that further polishing never improved accuracy.

Just another opinion from a fine machinist.

A. Weldy

luckyshot52

Silver $$ Contributor

I like to do it with scotch brite (@300 or so) to give it some smoothing and cross hatching . It is not polishing as such.

Pertaining to the oversize question. I would like to know how people are measuring the I.D. of a taper accurately and who on this site actually has the ability to do that? Especially with the small amount that polishing is going to change that.

Last edited:

Actually, the way I chamber (everything floats and the hole guides the reamer)When chambering any of you guys actually measure how much over reamer size a chamber really comes out? I hear talk of runout and only seems logical that if there is runout then chamber is a tad over reamer size. Second question is should polishing with flitz open up the chamber at all,.0001-2)? I bought a few pin gauges to check but am not ready to chamber yet.

I bought a tight 22lr reamer,.2242 at largest diam) and would like it to end up atleast .2245. I still need to to get an inside threading tool and build my spider. I can understand it would be difficult to tell exactly being as though reamers are tapered.

When talking to other machinists they said that with normal reamers and thicker oil that you get a tad larger hole over thinner water based fluid flooding. I will using pressurized coolant through the barrel.

I once spec'd out one of my reamers to Manson to be .001" oversize at the head dia.

(Wanted to save brass in case I loaded hot and wanted to prevent head expansion.)

When I finished chambering the barrel, the case went in but was not allowed to expand.

and I got Bolt Clicking (hard to extract) on majority of rounds even with starting loads.

------------

I had to enlarge the chamber in the head area .001" more to allow for brass expansion

--- No more bolt clicks

------------

Long story short, there should be no "Oversize chamber" over reamer dimensions if its done right.

------------

To measure you can measure

total OD

- the wall thickness x 2

Result is = Chamber dia.

----------------------------------------------------------

Same as if you want to measure brass neck

OD - bullet dia ( then divide by 2 ) = brass neck thickness

resolution will be determined by the resolution of your measurer

From eveything I've researched, this is the most agreed upon methodI like to do it with scotch brite (@300 or so) to give it some smoothing and cross hatching . It is not polishing as such.

Smooth polished chamber may extract easier but many believe it can create more bolt thrust

Or show pressure signs when there really isn't any (2 smooth surfaces do not grip well )

Cross hatch with scotch brite (I use brown after chambering)

Takes about 30 seconds

Spin lathe - spin Scotchbrite in drill = Done

--------------

So called "Polishing" does not remove material so much as it burnishes the surface

if anything it might remove 1/10ths, not thousandths

--------------

If you dont believe me take some 320 or 400 grit sandpaper to a Krieger and try to enlarge the chamber by any measureable amount ....even .001"

Pack a lunch because you'll be there for a good while

about an hour just to get that much.

Last edited:

I can. I have two CMM’s capable of doing do. However, I never have. That machine is better checking the parts that keep the lights on.Pertaining to the oversize question. I would like to know how people are measuring the I.D. of a taper accurately and who on this site actually has the ability to do that? Especially with the small amount that polishing is going to change that.

Easy......I measure my chamber cast at various points. Generally I'll usePertaining to the oversize question. I would like to know how people are measuring the I.D. of a taper accurately and who on this site actually has the ability to do that? Especially with the small amount that polishing is going to change that.

crocus cloth after reaming. This helps to make it easier to push out the

casting. If satisfied, I just do a cross hatch with 400 for straight wall cases,

and 300 with a more tapered case like the 300 Savage......My process.

Note......Brass wall hardness, and pressures being generated will skew

most arguments.

Yep, don't know where that got started, Butch and Dave are spot on.A highly polished chamber will grip the brass!

Butch

DaveTooley

Gold $$ Contributor

When I'm polishing a target barrel to a high polish, I can tell which areas have a higher polish while the lathe is still running. The smoother, more polished areas have a higher degree of friction with either the abrasive cloth or a Scotchbrite pad. I'm not sure why it matters one way or the other. Pull the trigger and the brass will fill the chamber.

mike mccormick

Silver $$ Contributor

Yep. The finer the finish, the more contact it makes.A highly polished chamber will grip the brass!

Butch

Correct, the softer brass will FILL, / FIT to the chamberWhen I'm polishing a target barrel to a high polish, I can tell which areas have a higher polish while the lathe is still running. The smoother, more polished areas have a higher degree of friction with either the abrasive cloth or a Scotchbrite pad. I'm not sure why it matters one way or the other. Pull the trigger and the brass will fill the chamber.

so with micro scratches, the brass will ballon into the voids between the scratches

= more Gription

What grips a barrel in a barrel vise more, Polished aluminum or sandpaper wrapped around the barrel?

------------

If you consider, that this dynamic is not the same thing as Tire Slicks having more friction

due to more contact area vs treaded tires.

Which is true in that dynamic. Simple surface contact

However if treaded tires bit into the pavement, then treaded tires would have more grip than slicks

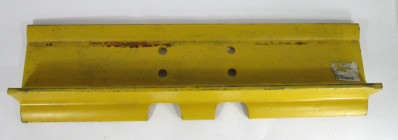

Just like the reason a Bulldozer has cleats on the tracks instead of being perfectly smooth

Attachments

Last edited:

There are different schools of thought on the subject: is one right and one wrong? I believe there have been several award winning highly accurate barrels done both ways. Personally i was taught to do a cross hatch, so thats the way I've done it for years and will continue to do it. I have yet to see a bolt with the lugs sheared off because of the finish on a chamber. Unless one method has been proven to be unsafe, id say continue on with what you think is best.

Similar threads

- Replies

- 6

- Views

- 4,262

- Replies

- 4

- Views

- 1,510

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.