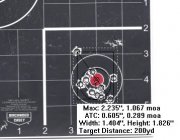

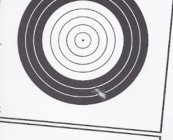

These groups are shot at 200 and 300 yrds prone from a Harris bipod and a sand sack, no wind flags. The 200 yrds is at a range and the 300 is shot on a farm across a gully. The grids on the targets are 1 inch.

Details;

105 A-max sorted base to Ogive

Lapua brass neck turned

Cases trimmed to length and chamfered

ADI2208 powder

CCI450 primer

Loaded = .267

Bushing = .266

Chamber = .271

SD = 7

ES = 20

All rounds are checked base to ogive at the time of seating and are within .002” spread. Runout is less than .002”

What would you work on to pull in the flyers (vertical). the 300yrd group has 3 at the very top and the 200yrd groups has 1 at the very top of the group – or am I asking too much from a Harris bipod, sand sack setup and no flags?

The vertical looks to me as though there is something that can be tweaked in the load as the groups look very consistent apart from the odd round going high.

These groups are the third firing on the brass and the neck tension is starting to vary.

I was thinking I would

1./ Anneal brass

2./ ?

-

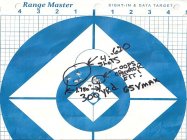

300_yrds.jpg

30.9 KB

· Views: 214

-

200_yrds.jpg

21.5 KB

· Views: 195

I would start with my neck tension. You only have a thousandth, and you need more like about 3 thousandths.

Run 'em across a chronograph & find out what the ED and SD numbers are. I would also agree, tighten up your neck tension. Another factor can be wind conditions as they relate to "shot on a farm across a gully".

Sorry I should have included SD and ES 7 and 20 - I have put them in the original post. Wind - yes that is accepted. To my eye there looks like some sort of load issue - i.e. I can easily see the horizontal scatter due to wind, but the vertical seems less random. Maybe its just my rookie eyes?

It looks a lot like Ronaka thread on flyers a while back. I was going to wait for him to post his results but impatience got the better of me

As others have said try a little more neck tension. Your ES is probably the issue. Just from looking at your targets. The shots that went high is what caught my attention. With a ES of 20 Thats what I would work on. (IMO)

Not bad shooting tho!

I'm also finding that as my brass age's with the number of loadings they require more neck tension. New Lapua seems fine with only .001" or .002". Down the road I seem able to maintain results with .003" or even as much as .004" (but that is maximum).

fivering said:

I would start with my neck tension. You only have a thousandth, and you need more like about 3 thousandths.

Not necessarily. Many records have been set with BRs or BR improveds with a thou (or less) of neck tension. That said, you might try a tighter bushing. But I don't think thats the issue. I think the much greater likelihood is that those couple of high shots are just the driver. Get to a bench with a good bag set-up and see if your vertical shrinks before messing with the load too much. Also next time MARK the CASES that give the flyer and leave them out of your next load up.

In all honesty, if you're just squeezin' a sand sock, I think most of your vertical is coming from that and inconsistencies of head contact on the gun. Off a bipod your targets aren't that bad at all. You just let a couple get away. What kind of barrel. If its a factory tube -- that could be an explanation. They're just erratic as they heat.

6BRinNZ said:

These groups are shot at 200 and 300 yards prone from a Harris bipod and a sand sack, no wind flags. What would you work on to pull in the flyers (vertical).

Not bad groups for 200 and 300 Yards. The first thing I would do is to eliminate every little bit of mechanical movement in that Bipod down to the last .001"[.001" movement at the rifle, moves point of impact by about 1/4" on the target at 100 yards]. I'd want it as solid as if it was one piece of metal.

To eliminate vertical I'd work on the load. Somewhere within a

.6 of a grain range, you're going to find a load where vertical should disappear. However, there are a bunch of things that can induce vertical, including any of these, which need to be eliminated one by one: http://www.accurateshooter.com/shooting-skills/cures-for-vertical-stringing/

How about milder primers? Have you tried BR4s, PMCs?

Smaller cases often like milder primers.

fdshuster said:

I'm also finding that as my brass age's with the number of loadings they require more neck tension. New Lapua seems fine with only .001" or .002". Down the road I seem able to maintain results with .003" or even as much as .004" (but that is maximum).

Yeah I have noticed the same thing - I am going to try annealing after every shot, just from a consistency point of view.

Forum Boss said:

fivering said:

I would start with my neck tension. You only have a thousandth, and you need more like about 3 thousandths.

Not necessarily. Many records have been set with BRs or BR improveds with a thou (or less) of neck tension. That said, you might try a tighter bushing. But I don't think thats the issue. I think the much greater likelihood is that those couple of high shots are just the driver. Get to a bench with a good bag set-up and see if your vertical shrinks before messing with the load too much. Also next time MARK the CASES that give the flyer and leave them out of your next load up.

In all honesty, if you're just squeezin' a sand sock, I think most of your vertical is coming from that and inconsistencies of head contact on the gun. Off a bipod your targets aren't that bad at all. You just let a couple get away. What kind of barrel. If its a factory tube -- that could be an explanation. They're just erratic as they heat.

Driver - could be, all of the shots felt good to me and when they pop out I am always suprised. Actually I was suprised when the first 5 were so close together. I did my load development of bags but I only ever used 3 or 5 shot strings. RCW mentioned on another thread that he found hot loads don't always stand up under long strings...I am wondering if I have an issue here as my load is hot.

I am working hard on my technique and slowly but surely it is starting to pay dividends. Its definitely a full custom rig...I couldn't spend better money.

Marking cases - yep got that under way. FJIM has given me some good tips on preparing a base set of cases to work with in other PMs.

Neck tension - This ones a dilemma as I hear what everyone is saying. Here is the thing though. With my freebore the bullet is well seated into the neck. The boat tail keeps the bullet out of the neck shoulder junction so no problems there. I think that so much of the bullet is held by the neck that tension ends up being tight. e.g. I have had to pull some of the rounds that I didn't end up shooting - using an RCBS bullet puller in a RCBS rock chucker I am really leaning on it to pull them up. The rounds had been seated less than 8 hrs so no weld issues.

By comparison a buddies 6BR throated to seat sierra 107s out is easy to pull out.

I think the article on neck tension on this site sums up this situation (http://www.accurateshooter.com/technical-articles/reloading/neck-tension-not-just-bushing-size/). Maybe I need to look at a better freebore to make things more "normal"?

Outdoorsman - thanks I have read the article previously and one thing I have learnt - lock in that pod lock real tight.

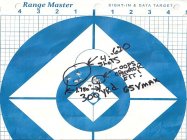

Primers - yeah I did comparisons between CCI400s and CCI450s in my ladder tests, I thought the 450s were better but I have gone back through my loads and I think I need to do more work to prove this. The 450s definitely gave me some amazing groups off the bags at 200 which I used as a basis for my loads. I have uploaded one of the 3 shot groups.

Thanks to all for the responses - I think the message is keep working the basics.

Any other tips or thoughts are appreciated.

-

200-bags.jpg

13.5 KB

· Views: 92

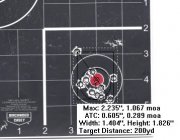

well i went this morning to practice 200 yrd group. oh it went bad, i said hey this aint a shotgun. then i got setteled down,changed my rear bag and my hold on the gun and 4 shots in the high.100's and lost one out to a .370 something. totally operator error. I was out of ammo. im going to get killed at 200 unless i get it figgured out soon. I had some varmit rounds loaded with a 65 v max so i put a target out at 300 yrds, and let 5 go. now it has been a few years since i have shot any 300 yrd groups. I lost a shot that i could see no condition for it, i cant say there wasent, but i dont think there was, its just a poor old flinch... and its gone.. its very hard to shoot 200 and 300 yrds, you have to be allmost perfect, you cant get away with gun handling mistakes like you can at 100 yrds.

6BRinNZ i would say yea try and see if you can tune the load or switch to another bullet and see if you still have the problem, and if you do.. look at your scope any parallax or eye position scope type problem, mirrage board ect.. you just cant get away with that stuff at 300 yrds.And if all is good you have to fix you...lol.....

6BR. 14 twist, 65 v-max, 300 yrds

-

42411 300 650001.jpg

68.3 KB

· Views: 132

Forum Boss said:

... Also next time MARK the CASES that give the flyer and leave them out of your next load up....In all honesty, if you're just squeezin' a sand sock, I think most of your vertical is coming from that and inconsistencies of head contact on the gun...If its a factory tube -- that could be an explanation. They're just erratic as they heat.

Learn something new everyday around here.

FJIM said:

6BRinNZ i would say yea try and see if you can tune the load or switch to another bullet and see if you still have the problem, and if you do.. look at your scope any parallax or eye position scope type problem, mirrage board ect.. you just cant get away with that stuff at 300 yrds.And if all is good you have to fix you...lol.....

6BR. 14 twist, 65 v-max, 300 yrds

FJIM - since I have measured base to ogive (105 A-max) I thought I would measure the bearing surface. Well I got a suprise here it is varying from .24325 - .24340, they all seem to have a slight high spot...i.e. slightly out of round. By comparison 80grn Noslers are bang on .24280. Probably no point in doing too much until I change the bullet.

6BRinNZ said:

FJIM - since I have measured base to ogive (105 A-max) I thought I would measure the bearing surface. Well I got a suprise here it is varying from .24325 - .24340, they all seem to have a slight high spot...i.e. slightly out of round. By comparison 80grn Noslers are bang on .24280. Probably no point in doing too much until I change the bullet.

I think you are on to something. I had a batch of 87gr V-Max. It was about the ONLY bullet that wouldn't shoot in my 6BR. I was puzzled... until I started measuring the

diameters of the bearing surface. There was a lot of variance, and some were out of round, as you've described.

Had a 600/1000 yd F Class practise today. Bright sun, 15C (60F), steady 10 click wind coming in from 11 o`clock swinging back and forth with 10 o`clock.

Trying 3 different bullets in my new 6.5AI Shilen Select Match barrel loaded over 48 gr RL22: 139 Scenar, 140 AMax, 142 SMK. Chronos around 2850 fps. Bolt lift sticking a bit now that it has warmed up coming out of the Winter. Will drop down to 47 gr RL22.

Canucks, Brits and Aussies shoot on the 5 ring ICFRA target. At 600 yds I was going back and forth across the one minute 5 ring with its 1/2 minute V-ring. Scoring enough Vs and 5s with the Scenars and SMKs in the switchy wind to be happy. The AMax were giving me drops into the 4 ring at 6 o`clock. The last shot on score with the AMax was a 3 at 9 o`clock. Looked like a good hold with no wind switch.

This is consistent with my experience with 105 AMax in a .243 and 6AI.

After lunch moved back to 1000. Scenars and SMK performing as expected. Have to be honest and say the AMax did not give a flyer. Same scores as the other two bullets. My shooting partner said I used up all the AMax flyers at 600.

I am not trying to be unfair to a particular bullet. Have never measured them for roundness. But I will not use AMax in competition. Only in practise. Just relating my own experience.

Yep - I agree with the sentiment on the A-max, I am sure there are better bullets.

I have some more A-maxs coming that are manufactured to Hornadys AMP...it will be interesting to see if there is an improvement against my previous measurements.

Hopefully I will have them next week.

AMPâ„¢ BULLET JACKET

Now featuring revolutionary new AMP (Advanced Manufacturing Process) bullet jackets! These new bullet jackets are a technological advancement in design, tooling and manufacturing that combine to produce the most consistently concentric bullet jackets available. Hornady AMP jackets are the foundation for exceptional bullet accuracy and have virtually zero tolerance for concentricity and near zero wall thickness variation.