Krogen

Gold $$ Contributor

Great post, 222Jim! Thank you. I appreciate your contributions in this thread. Much food for thought.Ah yes, case capacity.

How much water is enough? I agree that QuickLOAD's information is seemingly contradictory:

(i) The data input sheet specifies "Maximum Case Capacity. overflow" and the information box that opens up supports this by specifying "at case mouth overflow", but

(ii) On page 62 of the User Manual it is stated the capacity is based on "water even to end of case neck".

I tried to get to the bottom of this a while ago and, like Alice and the rabbit hole, ended up falling down into a deep dark rabbit hole into a strange and nonsensical world. In the end I took a pragmatic "split the difference" approach. My approach?

(i) First off, how much overflow? That last drop of water, depending on how much water was already in the case, could just fill the case so any overflow was microscopic, or that last drop could end up giving me a nice round convex water drop on top of the case. So,

(ii) I cut the water's surface tension, and hence it's ability to form a drop on top of the case, by adding a very small drop of dishwashing detergent to a cup of water. The with my eye dropper, just touch the water in the case with tiny drops of water at the case mouth until the water is just barely over the top.

As an added bonus, a little to much of this water/soap concoction will quickly result in the water easily running down the outside of the case if you try to add just a little too much water. Hence, it's a convenient check on my technique.

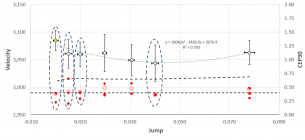

I do this twenty times and average the results:

View attachment 1621144

By the way, I tried using rubbing alcohol instead of water because several people suggested that (it's got less air dissolved in it and a much lower surface tension). Sadly, the standard deviations for the same cases got a lot larger, so I went back to my water & drop of soap method.

I also tried using primer plugs in clean cases instead of fired cases with fired primers in them. Just like my rubbing alcohol experiment, I ended up with worse results for the same cases.