You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brass neck turning question

- Thread starter kaden688

- Start date

I always turn prior to firing. All mine are tight necks so firing unturned brass not possible. I use regular turners not a machine like you are going to use, don't really know if it makes a difference.Is it best to neck turn brand new brass or fired brass? Im purchasing an autodod and need to know so I can get the correct case holder. Thanks guys!

The answer is.....it depends. If you have a tight neck chamber, you will need to turn necks prior to firing. For a standard chamber, I only turned the necks when the thickness varied .002 or more around the circumference. This was usually after about 5 firings.

PopCharlie

PopCharlie

RegionRat

Gold $$ Contributor

They will give you the best advice for the fit of their holder since they make them.

I don't find it makes a difference, but I have only run two different cartridges and those were both virgin Lapua and cycled brass didn't run any different.

I mandrel those virgin or used necks to be exactly the same no matter what, but the holder is grabbing the body and that fit is up to the dies and being pretty close to nominal shape and length. They felt the same in terms of grip going in and out of the holder.

BTW: the AutoDOD is a thing of beauty...

I don't find it makes a difference, but I have only run two different cartridges and those were both virgin Lapua and cycled brass didn't run any different.

I mandrel those virgin or used necks to be exactly the same no matter what, but the holder is grabbing the body and that fit is up to the dies and being pretty close to nominal shape and length. They felt the same in terms of grip going in and out of the holder.

BTW: the AutoDOD is a thing of beauty...

As mentioned, if you have a tight necked chamber, you'll want/need to turn them when they're virgin. . . . . and probably a second time after they're fire formed. Otherwise, I feel it's best to turn them only after they're fire formed to be sure that the cut into the shoulders are consistent.Is it best to neck turn brand new brass or fired brass? Im purchasing an autodod and need to know so I can get the correct case holder. Thanks guys!

Other than special cartridges, it makes sense is to turn new necks, prior to any firing of them.

With this, you touch the neck-shoulder junction so that area, once becoming a part of necks, is not an immediate donut. Once you've fired necks, before turning, you've missed that opportunity and would then have to inside ream donuts away.

Another thing better about turning new cases is that it's easier to get a correct fit on the turning mandrel when all you need to do is up-size with a mandrel. Otherwise, you would need to FL size necks, with an actual FL die, the right amount, for turning expansion and turning to follow. If you don't plan to FL size necks, I never would, that would take another die to do it (a non-bushing die).

Then you might wonder when to turn necks you plan to up-size or down-size.

Same deal. It's easier to trial & error turn virgin necks.

When you do a bunch of neck sizing, you'll migrate away from correct fit on the turning mandrel, as you're working the brass to different thickness.

With this, you touch the neck-shoulder junction so that area, once becoming a part of necks, is not an immediate donut. Once you've fired necks, before turning, you've missed that opportunity and would then have to inside ream donuts away.

Another thing better about turning new cases is that it's easier to get a correct fit on the turning mandrel when all you need to do is up-size with a mandrel. Otherwise, you would need to FL size necks, with an actual FL die, the right amount, for turning expansion and turning to follow. If you don't plan to FL size necks, I never would, that would take another die to do it (a non-bushing die).

Then you might wonder when to turn necks you plan to up-size or down-size.

Same deal. It's easier to trial & error turn virgin necks.

When you do a bunch of neck sizing, you'll migrate away from correct fit on the turning mandrel, as you're working the brass to different thickness.

Last edited:

RegionRat

Gold $$ Contributor

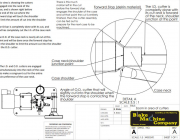

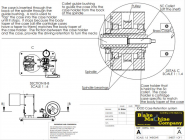

The IDOD/AutoDOD cuts the ID and OD simultaneously. So, the issue with the neck size is not pilotage, it is for balanced material removal.

I try for a very light but 100% clean up on the ID and remove the rest from the OD. The better my neck size workmanship is before hand, the less I find myself adjusting the process.

The issue of virgin versus fired with respect to piloting on the case holder, has to do with grip on the case body when you tap the case in and out of the machine. The machine picks up the body taper and that determines the position of the work piece. This system is different in that respect.

The drawings explain it better than my words, but because the shoulder is referenced by the Delrin shoulder stop or by the sensor, the ID is always cut clean and the OD and OD-Shoulder Junction is also controlled no matter how far in or out the case sticks based on the difference between virgin and fired.

That top right probe is what controls the feed of the cutters along the case body before the carriage stops.

To see it in action, you can check out his videos and web site.

https://www.fclassproducts.com/autodod

I try for a very light but 100% clean up on the ID and remove the rest from the OD. The better my neck size workmanship is before hand, the less I find myself adjusting the process.

The issue of virgin versus fired with respect to piloting on the case holder, has to do with grip on the case body when you tap the case in and out of the machine. The machine picks up the body taper and that determines the position of the work piece. This system is different in that respect.

The drawings explain it better than my words, but because the shoulder is referenced by the Delrin shoulder stop or by the sensor, the ID is always cut clean and the OD and OD-Shoulder Junction is also controlled no matter how far in or out the case sticks based on the difference between virgin and fired.

That top right probe is what controls the feed of the cutters along the case body before the carriage stops.

To see it in action, you can check out his videos and web site.

https://www.fclassproducts.com/autodod

RegionRat

Gold $$ Contributor

One thing is for sure.So it's not too complicated to turn new necks, right?

When faced with 500 or 2000 new ones, the AutoDOD is a godsend.

I try to run no-turn on most rigs. Sharing one of these with a few friends, makes life better. YMMV

Similar threads

- Replies

- 6

- Views

- 544

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.