All,

I am having a frustrating issue reloading and was hoping someone here could give me a little help.

Right now I am doing load development and barrel break in for a new rifle, and have fired my first 100 pieces of Lapua brass once.

After decapping and tumbling them, I'm running into issues resizing.

I'm trying to full length resize and bump my shoulder back ~.002", which seems simple enough.

My resizing die is a Redding S series, full length sizer. It has a neck bushing and the mandrel is removed.

After resizing, cases are consistently measuring .004-.005" LONGER than when they started, which seems impossible.

This is measured on a set of Starrett calipers that I know to be accurate, using a shoulder bump gauge that measures at mid shoulder - not OACL.

My press is a Forster Coax, and the die is as far down as is physically possible while still being able to cam over the press; it takes some noticeable effort. I can't lower it any further.

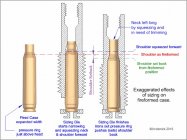

The die is also leaving a weird ring or distortion about mid-shoulder on the resized cases, which is easier to see in person but I did include a photo.

Needless to say this is perplexing. I feel like my dies, press, and method are 'good', and my measuring devices are telling me the truth, I just cannot see how this is occurring.

The resized cases will chamber, which also seems strange.

First photo is 1x fired, untrimmed brass - just decapped and cleaned. 2nd is after resizing, 3rd is the distortion the die is leaving on the shoulder.

**I am not using WD40 as lube, the can is just in the background. Imperial sizing wax, used as directed.

I am having a frustrating issue reloading and was hoping someone here could give me a little help.

Right now I am doing load development and barrel break in for a new rifle, and have fired my first 100 pieces of Lapua brass once.

After decapping and tumbling them, I'm running into issues resizing.

I'm trying to full length resize and bump my shoulder back ~.002", which seems simple enough.

My resizing die is a Redding S series, full length sizer. It has a neck bushing and the mandrel is removed.

After resizing, cases are consistently measuring .004-.005" LONGER than when they started, which seems impossible.

This is measured on a set of Starrett calipers that I know to be accurate, using a shoulder bump gauge that measures at mid shoulder - not OACL.

My press is a Forster Coax, and the die is as far down as is physically possible while still being able to cam over the press; it takes some noticeable effort. I can't lower it any further.

The die is also leaving a weird ring or distortion about mid-shoulder on the resized cases, which is easier to see in person but I did include a photo.

Needless to say this is perplexing. I feel like my dies, press, and method are 'good', and my measuring devices are telling me the truth, I just cannot see how this is occurring.

The resized cases will chamber, which also seems strange.

First photo is 1x fired, untrimmed brass - just decapped and cleaned. 2nd is after resizing, 3rd is the distortion the die is leaving on the shoulder.

**I am not using WD40 as lube, the can is just in the background. Imperial sizing wax, used as directed.