What kind of gun ? I always liked the challenge, getting the most out of it .

Super nice casting job, I only wish mine would come out that nice. Enfield???

What kind of gun ? I always liked the challenge, getting the most out of it .

Super nice casting job, I only wish mine would come out that nice. Enfield???

Hex receiver Mosin wish I bought a Enfield when I had the chance. Was a stint when they where all over the place for $100 then they just vanished

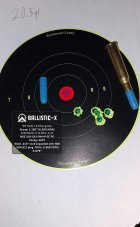

Tried shooting my first loads off my tripod because of the rain but after tryin to get a cow out of the way I could barely see so ended up shooting this wonderful group @50...which for some reason is what you supposed to do load development with cast at. Don't really understand it but it's what everyone the cast community does so

View attachment 1483908View attachment 1483909View attachment 1483910View attachment 1483911

View attachment 1483908View attachment 1483909View attachment 1483910View attachment 1483911

Tired again the next day but after shooting all 20 test loads I found out my scope rings where loose ...was wondering why I couldn't keep on target. Also noticed I had leading for the first time in my little casting career. Confused me because I used basically the same methods to shoot cast out my 5.56 ar at up to 2500 with no leading.

View attachment 1483912

Well after I scrubbed it all out went down the check list and only thing I could think of was my alloy. I got some sheet lead to play around with and had been adding it to my mix. Figured the little I added wouldn't hurt.... Well checked one of my bullets from that mix and instead of the usual 16bhn I start off with I was at 6bhn....way too soft.

View attachment 1483913

So that explained that made a new batch with a harder alloy along with water quenching after dropping out the mold and after powder coating , got it up to 15 today

Sir, that is a look of determination!! Good job!

Very cool and very interesting. I’ll be watching this thread. Thanks! Neil

Keep it up. Its a long winter. Once you find the magic you can really pile up the ammunition

A man on a mission! Good luck.

Those things can have layer after layer of crap. I have cleaned a few in various ways, from the electric side of things to plugging the bore and letting it set full of Kroil.

As far as loads, I have had success with using 10% reduced jacketed data.

I have a Finnish Nagant, well worth what I paid for it. I rank it and the K31 right at the top of the heap for mil surps, even over 1903 and 03A3’s.

You really need to get all of the gilding metal and or carbon out. Hard alloy and coated bullets may help cover underlying issues, yet still not show the real accuracy potential with jacketed and cast.

If you have time, could you explain about the devise you are testing hardness with? I am going to need to get into this soon as I want to cast rifle bullets as well as the handguns i am doing now.

Now I also use a NOE expander plug instead of the lee system. You guys who mess with sizing mandrels can probably get the jist of what these are.

NOE's expander setup is slick, use them for every caliber I cast!

If you have time, could you explain about the devise you are testing hardness with? I am going to need to get into this soon as I want to cast rifle bullets as well as the handguns i am doing now.

For me, the Lee tester is too finicky so I went with the Cabine Tree tester instead.

If you have time, could you explain about the devise you are testing hardness with? I am going to need to get into this soon as I want to cast rifle bullets as well as the handguns i am doing now.

Sure ! All it is is the lee harness tester with this little 3d printed stand . I bought it used and it came with the stand. Makes life easier because all you have to do is really move the bullet instead of trying to be an octopus and hold the light microscope ect. It work but honestly I'd go with a nicer system if you can .

Sure ! All it is is the lee harness tester with this little 3d printed stand . I bought it used and it came with the stand. Makes life easier because all you have to do is really move the bullet instead of trying to be an octopus and hold the light microscope ect. It work but honestly I'd go with a nicer system if you can .

View attachment 1484243View attachment 1484244View attachment 1484245

Interesting thread.

I am curious if you need to cast the chamber. Can you take measurements of the fired brass and get much of the same information?

Although if you do cast the chamber, post a documentary thread. You did a fine job of walking us through this one. Even I understood some of it.

Thanks, I looked up the Lee tester but just saw the metal parts , the stand had me confused. I have mostly soft lead but have some wheel weights that I cast as ingots and are mixed in with the soft stuff. At some time I need to up my game and separate them and learn to make a harder alloy. Soft lead and tin 20 to 1 seems to work for my 38 spc loads and I have a bunch of 9mm loaded but my eyes were stopping me from wasting it. But now i have eyes again.