The Savage nut was developed to allow quick and precise head spacing on the assembly line. It saves labor costs and reduces rework. It does not save material or machining costs since additional parts always increase those costs. Remington and Ruger also recognized the advantages for their new lines of rifles.RWO

Tell me if I get this wrong;

Remington or Savage, a machine runs the reamer in xx.xxx far, and then a machine finishes the barrel including threading. That Remington or Savage threading better take the breech to correct clearance from boltface, and headspacing will work only if the reamer had run in right.

In either case these things would have to be checked, and it would be a bit of extra attention to fix issues.

Right?

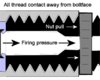

As far as the threading itself, Savage is finer, and the nut seats ALL of the savage threading in tension, rather than just the first few with a Remington. The Savage threading is biased

away from the boltface by the nut(same direction as challenged on firing). Otherwise the first few threads pull threading

toward the boltface, and the remaining are further relaxed opposite on firing.

Savage's system provides a better connection, just as any stud/nut system does.

The floating bolt head is brilliant provided it's machined square, and of course this is critical regardless of approach.

If you've priced a BAT bolt lately, you might recognize the potential value (resale) in such a system -if there were BAT boltheads offered. But they aren't..

I like the spirit behind someone putting a barrel nut on BAT.

Though I wouldn't do it without having BAT thread an action matching that of Savage (fine and same diameter for cartridge).

If I did anything otherwise unique to Savage, I would do it exactly as their Engineering had.