rwj

Gold $$ Contributor

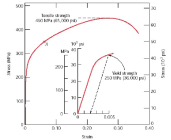

What is the modulus of elasticity of cartridge brass?You guys “think” you’re all that and a bag a chips . There is in fact stages of annealing and VERY good reasons for it . It’s not an all or nothing proposition as some might believe . It appears some here can’t see the forest through the trees . Any of you expersts anneal your AR10 cases to 1200 degrees ? No - Didn’t think so cus you’d have to little bullet hold and jam the bullet into the case as it’s chamberd . Grain structure starts to change somewhere around 500* and 750* to 800* is perfect to relieve stress of very thin sheets of brass like cartridge case walls while still leaving some work hardening in the necks for more bullet hold . This reduces the possibility of bullet set back on aggressive auto loaders while also allowing for more reloads per case before necks start splitting/cracking . In these types of rifles you are not looking for “perfectly” prepped cases because they are so hard on cases in the first place . Generally when annealing auto loading cases you are looking to stress relieve to get a few more reloads out of the cases rather then bench rest quality case prep .

Just because you know one thing and know it well doesn’t mean you know everything!

Is the elastic modulus constant or does it vary with material hardness?

Is material hardness related to the yield strength of cartridge brass?

How does ductility effect bullet holding force?

Last edited: