powderbrake

Gold $$ Contributor

I have been shooting off the bench and prairie dog shooting off a rotating bench for many years. I have been using a McMillan A3 stock with an adjustable cheekpiece, and have had difficulties keeping the scope hairs level when shooting prairie dogs. I decided I needed a 3" wide fore end like my benchrest gun.

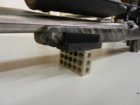

I purchased a SEB Mini rest and added the FClass products Mini Mod Top. Then I had an aluminum plate machined to fit the stock, 3" wide with 1/2 square corners to ride the bag. This worked pretty well but I think I lost a little accuracy.

I saw the underside was rubbing an the bag, the 1/2 ends were too heavily loaded by the rifle weight to keep the middle off the bag. Tried the very full bag, but got some vertical with the really hard bag.

So I needed a full width part. Having given myself a 3D plastic printer for Christmas.

I struggled learning the 3D cad program, but finally managed to print a 3" bag rider. It took 5 1/2 hours to print it.

I had previously added 3 #8-32 threaded inserts to the fore end.

I purchased a SEB Mini rest and added the FClass products Mini Mod Top. Then I had an aluminum plate machined to fit the stock, 3" wide with 1/2 square corners to ride the bag. This worked pretty well but I think I lost a little accuracy.

I saw the underside was rubbing an the bag, the 1/2 ends were too heavily loaded by the rifle weight to keep the middle off the bag. Tried the very full bag, but got some vertical with the really hard bag.

So I needed a full width part. Having given myself a 3D plastic printer for Christmas.

I struggled learning the 3D cad program, but finally managed to print a 3" bag rider. It took 5 1/2 hours to print it.

I had previously added 3 #8-32 threaded inserts to the fore end.