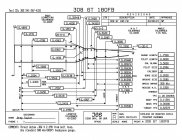

Next, you need to start taking and recording some critical measurements, if you haven't done so already. The taking and recording of accurate measurements is sometimes the only way one can readily troubleshoot problems such as this, and it's generally just a good practice. For example, measure the case diameter at the datum line just above the extractor groove (circled in red on the following .308 Win Cartridge/Chamber diagram from SAAMI). Doing this before/after firing can provide some idea of how much case expansion is taking place in your chamber.

View attachment 1451925

In addition, taking and recording base-to-shoulder (BTS) measurements can also be critical. It is sometimes possible for the case shoulder is bumped back excessively during the re-sizing process (i.e. > .002" or so). When the firing pin hits the primer cup, it drives the case forward until the case shoulder "bottoms out" in the chamber. If the case BTS dimension is too small (i.e. the shoulder has been bumped back too far), this can create an excessive gap between the base of the case and the bolt face as the firing process proceeds, allowing primers to "pop out", even in cases where the pressure may not be over MAX. It may not seem like a tiny gap of only a few thousandths could cause this to happen, but I can assure you it does. For this reason, it is not uncommon to observe popped primers when fire-forming virgin brass, which is usually much shorter (BTS) straight out of the box than it will be after the first firing/re-sizing cycle. Seating bullets long to prevent this tiny gap from opening up may help with virgin brass, but it's not really where you want to be with fire-formed brass, where optimal bullet seating depth is absolutely necessary for good precision. Make sure you are sizing your case back at the shoulder by no more than .001" to .002" during the re-sizing process.