Hello

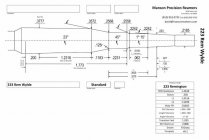

Im looking to have my trusty 223 Tikka barrel replaced and I'm wanting to get my own reamer. I currently use a LE Wilson FLS bush die and would like to have the reamer work with it.

I have taken some measurements of fired brass an FLS brass that chambers nicely in my current Tikka chamber (which I guess would be SAAMI?)

Is it as simple as sending these measurements to someone like Manson and have them input those measurements into a 223 reamer? Or am I way off on this?

Any info appreciated, cheers

Im looking to have my trusty 223 Tikka barrel replaced and I'm wanting to get my own reamer. I currently use a LE Wilson FLS bush die and would like to have the reamer work with it.

I have taken some measurements of fired brass an FLS brass that chambers nicely in my current Tikka chamber (which I guess would be SAAMI?)

Is it as simple as sending these measurements to someone like Manson and have them input those measurements into a 223 reamer? Or am I way off on this?

Any info appreciated, cheers