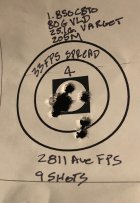

Ned:

Thank you for your response. Quite interesting. I'm not the best group shooter, at 66 years old i'm glad to be shooting. That black square is .750". I've shot tighter groups , Some below 1/2" center to center, 5 shot when i'm doing well. Maybe i'm being too anal about the extreme spread. At 100 yards it matters little right, at 600 to 1000 it matters more. My thought was to ge the lowest extreme spread load and then tweak for group size instead of other way around. When i talked to some very good shooters about the velocity spread first thing they asked was how i'm measuring my powder, told them on a beam scale, told me to get a better scale, I did and guess i was expecting better results than what i'm getting.

With the small .223 Rem case, pretty much everything matters when it cones to ES/SD. Precise charge weights, consistent neck tension, having the right powder for the bullet you're pushing, and the right primer to go with that powder; all these things can have an effect on velocity. Everything seems to matter just a little more with .223 Rem loads as compared to a larger case like the .308 Win.

I agree with your thought about looking for the low ES/SD window first, then using seating depth to shrink the groups. That's the approach many use, and it certainly can work. On occasion however, particularly with a new bullet I haven't used before, I'll start out with what I know to be a safe [slightly reduced] charge weight and do a seating depth test to get some idea of where the new bullet might want to be seated. Then I go back and do the usual charge weight testing, followed by seating depth optimization. Regardless of the order in which you carry out the steps, it is possible to end up at the same place.

Another thing to consider about all the different sources of variance you will encounter during the loading and testing process, it is usually not too difficult to get some idea of how much effect each one has using various computer programs. Although these exercises are predictions only and not written in stone, they can give one a better feel for what might be the limiting source of error. For example, the reloading program Quickload can provide estimates for how much increase in velocity can be expected from a 0.1 gr increase in charge weight, or a small change in case volume. Again, these values are not written in stone, but they can provide a basis for better focusing on things likely to help, rather than going down the rabbit hole of chasing variables that are unlikely to be the primary [largest] sources of error. In .223 Rem loads, an increase in charge weight of 0.1 gr is usually good for somewhere in the neighborhood of 5-10 fps increase in velocity. My point is that your beam scale was likely more than capable of weighing powder to 0.1 gr precision, so it's unlikely given that +/- 0.1 gr charge weight variance should only produce about +/- 5-10 fps velocity variance that the beam scale was the

primary source of your 33-36 fps ES. Likewise, you can use many of the available ballistic programs to make similar estimates regarding the effect of velocity variance in terms of vertical dispersion on the target at some specified distance. Again, these are useful tools to facilitate and expedite the reloading process and our understanding of exactly what is going on when we do certain things, but they will never take the place of actual test results. I view their use largely as sort of a sign post to help point me in the right direction.

The reason I mention all this is that the various sources of error we encounter during the reloading process are usually additive. It is generally easiest and the most beneficial to find the

largest, or limiting source of error, first. Just as a completely hypothetical example, if you have a couple small sources of error that might be contributing 5 fps here and there to your extreme spread, and one large source that is responsible for 20-25 fps ES, then finding and solving the larger source or error will have the greatest and most noticeable impact on bringing down your ES. Until you identify and solve the larger source of error, trying to fix the very small sources one by one that collectively might still noticeably impact your ES is likely to be an exercise in frustration. Always go for the biggest source of error first, which as I noted above was probably not your beam balance.

So what are likely to be the largest potential sources of error?

1) As several people mentioned, consistent and proper neck tension is a big deal with the .223 Rem. I have also found that sizing cases first with a bushing die (I use Redding Type S Match Dies] and the appropriate bushing, followed by a mandrel to open up the necks to the desired neck tension (interference fit) gives me the best results. In my hands, neck tension of .0015" to .0020" has given the best results for .223 Rem loads with heavy bullets over H4895. With Lapua .223 Rem brass, a 0.248" bushing would give me very close to .002" neck tension. So I might use a a 0.247" or 0.246" bushing first to make sure all the necks were tightened up a little bit

beyond what the selected mandrel would open them up to, then come back and run the mandrel through each case as the final sizing step.

When opening necks up from a smaller size to a larger, spring-back of the brass works in the opposite direction than when sizing necks down from the outside with a bushing. That is, the necks will close up about half a thousandth after the mandrel is removed. I use bullet diameter, which in this case is 0.224", as a guide to decide which mandrel(s) to try. So in my hands, a mandrel of 0.2225" diameter, which is only .0015" below bullet diameter will give very close to .002" neck tension when used as following slightly over-sizing the necks down with a bushing die as described above. This is because the spring-back of the brass will add about another .0005" of neck tension. Likewise, a .2230" mandrel should give very close to .0015" neck tension, and a 0.2220" mandrel should give close to .0025" neck tension. I use the mandrels from 21st Century, in the Gen II Expander die from Sinclair:

Brownells has 236 SINCLAIR INTERNATIONAL products for Sale Up To 91% Off including Reloading, Tools & Cleaning, and Gear.

www.sinclairintl.com

There are certainly other choices that would also do the job.

2) Another thing I'd consider testing is a couple different primers. Changing primers can sometimes have a huge effect on ES/SD. Even different Lots of the same primer can sometimes make a noticeable difference. Unfortunately, if you don;t already have a few different types of primers, now is not a particularly good time to try and find them with the current shortage. Maybe a friend has a few of a different type you could test until such time as they become readily available again.

3) I weight-sort all my brass prior to loading for F-TR matches. In my hands, there is a strong correlation between case weight and case volume. Although the relationship is not perfectly linear, heavier cases generally have less internal volume than lighter cases. So it is possible to sort your brass into 3 or 4 distinct weight groups, which may have a small beneficial effect on your ES by improving the consistency of the internal case volume within a given weight group. Again, this is not perfect; it is not uncommon to find an outlier here and there, even in weight-sorted brass, but it is generally possible to end up with more consistent internal case volume by weight-sorting brass than by doing nothing at all. Determining case water volume is also a possibility, but it is a pretty painful process to do with the requisite accuracy and I personally wouldn't attempt it with large numbers of cases. You didn't mention what your scale upgrade was from the balance beam, but if you have an electronic balance, weight-sorting brass is very fast and easy, so why not give it a try?

In summary, these are three suggestions as to things you might consider testing in your quest to lower ES/SD (i.e. size neck with a mandrel, test different primers, sort cases by weight). There are certainly other things you could try, but those three approaches are not too painful or expensive should you decide to pursue any or all of them. One thing not to lose sight of as I mentioned in the previous post is that you may have already reached the point of limiting return with regard to you rifle setup. A production rifle with 20" barrel may not necessarily be amenable to producing sub-30 fps ES values for a variety of reasons. So I wouldn't suggest going too far down the rabbit hole chasing ES values under 20 fps if the rifle setup itself may be the limiting source of error. That is one reason why I previously suggested tightening up the groups as best as you can first, then worrying about ES later when you have the time and inclination. Never lose sight of the real reason we do this stuff, and that is to have fun. Best of luck with it!