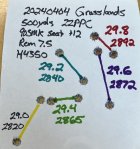

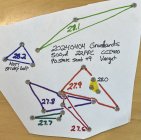

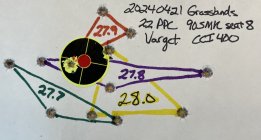

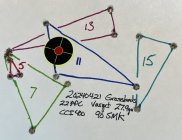

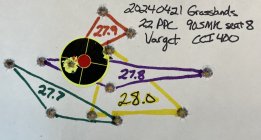

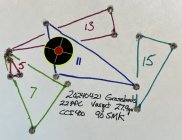

Evan, Interesting project. I've been dinking around with a couple of 22 Grinch rifles, with bullets up to the Berger 85.5 hybrid, at velocities a bit above 2900 out of 23" & 24" bbls. The Grinch has a slight increase in case capacity over the 22 PPC, as you can see in the attached photo. My reamer print shows a neck dia. of .254", and with the Starline brass I'm using, not neck turned, I get a loaded neck dia of .252". I turned a batch of this brass down to the point where loaded necks are at .248", so will set the turner to take just a clean-up cut for the next batch of brass. Would like to wind up with loaded neck dia of .251". Not very far along with testing for accuracy, and not sure that the Berger 85.5 Hybrid is the bullet to use. So far, I've only used Alliant PP2000MR & N540 powders with the heavier bullets in the Grinch rifles.

I've got some JLK 90VLDs from years ago when Jimmy still had the bullet making business, and they shot very well out of a couple of 223AI bolt rifles - as have some older Berger 90VLDs - but have yet to try any of them in either of the Grinch rifles. Looking forward to seeing more of your results as you have time to shoot more...

I've got some JLK 90VLDs from years ago when Jimmy still had the bullet making business, and they shot very well out of a couple of 223AI bolt rifles - as have some older Berger 90VLDs - but have yet to try any of them in either of the Grinch rifles. Looking forward to seeing more of your results as you have time to shoot more...