Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

20 Practical Reloading Issue

- Thread starter lgwatson

- Start date

lgwatson

Silver $$ Contributor

These two groups prove that a 9 twist works.You dont need a 8 twist.

Theres 20VT out there that shoot 55's with a 9. This 8 vrs 9 thing has been beat to death.

Numbers are just that real world experience is what counts and thers several people on here that shoot 9's with great success including me.

Loaded round neck O.D is .230. These once fired were full sized with Redding 20 Practical die and expanded with a .203 Sinclair expander mandrel.Ok what size bushing are you using?

Lapua is thicker than most brass, most brass

.225 or .226 is what you want but maybe not Lapua. My guess is your .230 or more on a loaded round neck with Lapua

L.Sherm

Silver $$ Contributor

K. Well the reason I'm asking about a print most all 20 prac reamers have a .232 nk chamber so you probably have very little wiggle room for a carbon ring, I would measure a fired case neck too if its .2315-.232 well then there's your answer on that.

Theres also .374 reamers at the base out there also that will also be a problem unless you use a small base die especially with Lapua brass on the small base reamer.

It may not show up on the first firing if you have that .374 reamer or use mild loads.

Looking at a reamer print would be very helpful to diagnose any potential problems that could arise.

My 20 Prac reamer is .3769 at the base and my Redding 223 FL die sizes the base to .375 give or take .0001 thats with LC 223 brass.

Most new 223 brass is about .3735 at the bass but Lapua could be bigger it typically is on most Lapua brass but ive never measured new 223 Lapua brass.

Theres also .374 reamers at the base out there also that will also be a problem unless you use a small base die especially with Lapua brass on the small base reamer.

It may not show up on the first firing if you have that .374 reamer or use mild loads.

Looking at a reamer print would be very helpful to diagnose any potential problems that could arise.

My 20 Prac reamer is .3769 at the base and my Redding 223 FL die sizes the base to .375 give or take .0001 thats with LC 223 brass.

Most new 223 brass is about .3735 at the bass but Lapua could be bigger it typically is on most Lapua brass but ive never measured new 223 Lapua brass.

Last edited:

lgwatson

Silver $$ Contributor

LG is it possible to get a print of your reamer that was used? Your smith should have one unless it was your reamer in that case the reamer manufacturer should have provided one.

Attachments

I'm not trying to offend anyone here, but I'm seeing members asking for numbers to try and figure out what's going on, and the information being provided is spotty and mismatched (IMHO). I have NO CLUE what the problem is, but maybe it would be worth taking ALL of the measurements so that everyone here had the all the information. Off the top of my head, these are the numbers I'd be looking at.

1. Virgin empty brass Neck OD (after sizing, ready to load)

2. Virgin loaded neck OD

3. Once fired neck OD (dirty, not sized)

4. Once fired sized neck OD (no expander)

5. Once fired sized neck OD (with .203 expander)

6. Once fired loaded neck OD

In my mind, the measurements from 1 and 5 should be identical since both went through the sizing die, and both had the .203 expander pulled back through them afterwards.

You might also want to measure the case head diameter on a piece of new virgin brass, sized virgin brass, once fired (dirty) brass, and once fired sized brass. That would give you an idea of how much you sized the body of the original brass vs how much you're sizing the once fired brass.

FWIW, I went away from the Hdy One Shot a few years ago. I just wasn't getting consistent coverage on my brass. I'd lube in 50 pc batches until I had 200-300 pcs ready to size, but I'd end up having problems with 5 or 6 of them going through my sizing die. I have some old RCBS lube that I've been using but I'm now switching over to Imperial. Takes longer, but I'm going through less than 1k/yr so I don't need to be in a rush so long as I plan ahead.

1. Virgin empty brass Neck OD (after sizing, ready to load)

2. Virgin loaded neck OD

3. Once fired neck OD (dirty, not sized)

4. Once fired sized neck OD (no expander)

5. Once fired sized neck OD (with .203 expander)

6. Once fired loaded neck OD

In my mind, the measurements from 1 and 5 should be identical since both went through the sizing die, and both had the .203 expander pulled back through them afterwards.

You might also want to measure the case head diameter on a piece of new virgin brass, sized virgin brass, once fired (dirty) brass, and once fired sized brass. That would give you an idea of how much you sized the body of the original brass vs how much you're sizing the once fired brass.

FWIW, I went away from the Hdy One Shot a few years ago. I just wasn't getting consistent coverage on my brass. I'd lube in 50 pc batches until I had 200-300 pcs ready to size, but I'd end up having problems with 5 or 6 of them going through my sizing die. I have some old RCBS lube that I've been using but I'm now switching over to Imperial. Takes longer, but I'm going through less than 1k/yr so I don't need to be in a rush so long as I plan ahead.

lgwatson

Silver $$ Contributor

I will fire a few to get measurements 3-6. I will send them.I'm not trying to offend anyone here, but I'm seeing members asking for numbers to try and figure out what's going on, and the information being provided is spotty and mismatched (IMHO). I have NO CLUE what the problem is, but maybe it would be worth taking ALL of the measurements so that everyone here had the all the information. Off the top of my head, these are the numbers I'd be looking at.

1. Virgin empty brass Neck OD (after sizing, ready to load)

2. Virgin loaded neck OD

3. Once fired neck OD (dirty, not sized)

4. Once fired sized neck OD (no expander)

5. Once fired sized neck OD (with .203 expander)

6. Once fired loaded neck OD

In my mind, the measurements from 1 and 5 should be identical since both went through the sizing die, and both had the .203 expander pulled back through them afterwards.

You might also want to measure the case head diameter on a piece of new virgin brass, sized virgin brass, once fired (dirty) brass, and once fired sized brass. That would give you an idea of how much you sized the body of the original brass vs how much you're sizing the once fired brass.

FWIW, I went away from the Hdy One Shot a few years ago. I just wasn't getting consistent coverage on my brass. I'd lube in 50 pc batches until I had 200-300 pcs ready to size, but I'd end up having problems with 5 or 6 of them going through my sizing die. I have some old RCBS lube that I've been using but I'm now switching over to Imperial. Takes longer, but I'm going through less than 1k/yr so I don't need to be in a rush so long as I plan ahead.

lgwatson

Silver $$ Contributor

I will.The difference between the neck diameter OD before and after bullet seating.

RegionRat

Gold $$ Contributor

The 9 twist works fine.These two groups prove that a 9 twist works.

My friends and I run the Berger 55 in 9 twist with wildcats that push it well over 3650 fps, and that extra speed gets the SG in the 1.4+ territory. I can also tell it is happy because the trajectory out past 600 yards matches the predictions, so the BC is happy.

Note that the altitudes I hunt are not near sea level, and that DA makes a big difference. This is why they recommend the 1:8 in short, but when the answer is expanded to include altitude the story improves so the 1:9 works out.

If an SG starts to get closer to 1, then things like winds and little bullet defects will cause some of them to fly with a little axis wobble that degrades the BC performance.

The 20 Practical may not be as fast as my wildcats, but say your SG might only be in the range of 1.3. With an SG in that class, it takes a lot of wind or bullet defect to create an issue.

The only reason to watch it at all, is when we are going out in winds where shooting to distance may show signs of the BC being a little worse and giving you a vertical spread.

I doubt a 20 Practical user is shooting the cartridge out that far, so the short range groups will likely extrapolate far enough to make you happy with an SG in the 1.3 range.

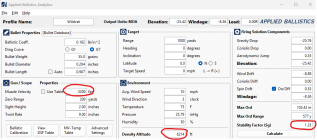

To show the model of why it works, I'll use the AB software that calculates the SG and exterior ballistics and happens to have a very good model of the Berger 55 in the library.

I guessed a MV of 3200 for this model, and you can see the 1:9 twist does fine at a DA of 6200 ft. At sea level, it may drop to an SG of closer to 1.1 where you would be sensitive to wind and the slightest defects.

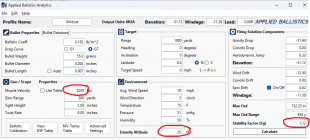

Now put the altitude near sea level and we see the SG drop significantly.

lgwatson

Silver $$ Contributor

I have used the Hornady One Shot Lube in multiple calibers and several thousand rounds and not had this problem.I'm not trying to offend anyone here, but I'm seeing members asking for numbers to try and figure out what's going on, and the information being provided is spotty and mismatched (IMHO). I have NO CLUE what the problem is, but maybe it would be worth taking ALL of the measurements so that everyone here had the all the information. Off the top of my head, these are the numbers I'd be looking at.

1. Virgin empty brass Neck OD (after sizing, ready to load)

2. Virgin loaded neck OD

3. Once fired neck OD (dirty, not sized)

4. Once fired sized neck OD (no expander)

5. Once fired sized neck OD (with .203 expander)

6. Once fired loaded neck OD

In my mind, the measurements from 1 and 5 should be identical since both went through the sizing die, and both had the .203 expander pulled back through them afterwards.

You might also want to measure the case head diameter on a piece of new virgin brass, sized virgin brass, once fired (dirty) brass, and once fired sized brass. That would give you an idea of how much you sized the body of the original brass vs how much you're sizing the once fired brass.

FWIW, I went away from the Hdy One Shot a few years ago. I just wasn't getting consistent coverage on my brass. I'd lube in 50 pc batches until I had 200-300 pcs ready to size, but I'd end up having problems with 5 or 6 of them going through my sizing die. I have some old RCBS lube that I've been using but I'm now switching over to Imperial. Takes longer, but I'm going through less than 1k/yr so I don't need to be in a rush so long as I plan ahead.

lgwatson

Silver $$ Contributor

Most of my shooting is at 3400-3600 altitude. Once in awhile higher. I will try this one at about 900-1000 feet and see what happens.The 9 twist works fine.

My friends and I run the Berger 55 in 9 twist with wildcats that push it well over 3650 fps, and that extra speed gets the SG in the 1.4+ territory. I can also tell it is happy because the trajectory out past 600 yards matches the predictions, so the BC is happy.

Note that the altitudes I hunt are not near sea level, and that DA makes a big difference. This is why they recommend the 1:8 in short, but when the answer is expanded to include altitude the story improves so the 1:9 works out.

If an SG starts to get closer to 1, then things like winds and little bullet defects will cause some of them to fly with a little axis wobble that degrades the BC performance.

The 20 Practical may not be as fast as my wildcats, but say your SG might only be in the range of 1.3. With an SG in that class, it takes a lot of wind or bullet defect to create an issue.

The only reason to watch it at all, is when we are going out in winds where shooting to distance may show signs of the BC being a little worse and giving you a vertical spread.

I doubt a 20 Practical user is shooting the cartridge out that far, so the short range groups will likely extrapolate far enough to make you happy with an SG in the 1.3 range.

To show the model of why it works, I'll use the AB software that calculates the SG and exterior ballistics and happens to have a very good model of the Berger 55 in the library.

I guessed a MV of 3200 for this model, and you can see the 1:9 twist does fine at a DA of 6200 ft. At sea level, it may drop to an SG of closer to 1.1 where you would be sensitive to wind and the slightest defects.

View attachment 1646938

Now put the altitude near sea level and we see the SG drop significantly.

View attachment 1646941

L.Sherm

Silver $$ Contributor

From what I see on the reamer numbers you should be fine, I would want the .200 line bigger with Lapua brass.

One concern I have is the .2039 freebore dia I've never seen or have anything that small normally its .2045.

Tread lightly it very well could pressure up quick if those numbers are correct.

Your closer to .233 on nk dia thats better than .232 with Lapua brass.

All this being said I dont think your problem you came here with has anything to do with things I described just things to pay attention too

One concern I have is the .2039 freebore dia I've never seen or have anything that small normally its .2045.

Tread lightly it very well could pressure up quick if those numbers are correct.

Your closer to .233 on nk dia thats better than .232 with Lapua brass.

All this being said I dont think your problem you came here with has anything to do with things I described just things to pay attention too

L.Sherm

Silver $$ Contributor

I'd shoot the thing and just forget about itMost of my shooting is at 3400-3600 altitude. Once in awhile higher. I will try this one at about 900-1000 feet and see what happens.

lgwatson

Silver $$ Contributor

Thank you.Lg

I think Berger makes a run of the .20 55 gr. Once a year for one of the big gun stores.

One of these guys should know.

Keep up the good work.

Hal

lgwatson

Silver $$ Contributor

The base of new and sized are both .375. The loaded rounds fit in the gun. The new brass full sized with the same sizer did not have the real tight neck tension that the one fired had.K. Well the reason I'm asking about a print most all 20 prac reamers have a .232 nk chamber so you probably have very little wiggle room for a carbon ring, I would measure a fired case neck too if its .2315-.232 well then there's your answer on that.

Theres also .374 reamers at the base out there also that will also be a problem unless you use a small base die especially with Lapua brass on the small base reamer.

It may not show up on the first firing if you have that .374 reamer or use mild loads.

Looking at a reamer print would be very helpful to diagnose any potential problems that could arise.

My 20 Prac reamer is .3769 at the base and my Redding 223 FL die sizes the base to .375 give or take .0001 thats with LC 223 brass.

Most new 223 brass is about .3735 at the bass but Lapua could be bigger it typically is on most Lapua brass but ive never measured new 223 Lapua brass.

lgwatson

Silver $$ Contributor

I'd shoot the thing and just forget about it

lgwatson

Silver $$ Contributor

The gun shoots like a dream. Too much neck tension and running it through the sizer is so tight even with Imperial lube, I'm concerned about a case sticking in the die. Next firing I am going to neck size only. The main frustration is the inconsistent BTOs when seated. I didn't have that issue with the new full sized brass after using the .203 expander mandrel.

L.Sherm

Silver $$ Contributor

K, then that means you have only .0004 diff between chamber and sized brass which isn't very much, at some point clickers may happen and your gonna have to get a small base die, the .3769 would have been perfect for you but it is what it isThe base of new and sized are both .375. The loaded rounds fit in the gun. The new brass full sized with the same sizer did not have the real tight neck tension that the one fired had.

lgwatson

Silver $$ Contributor

Thank you for all your help. I'll try that also.K, then that means you have only .0004 diff between chamber and sized brass which isn't very much, at some point clickers may happen and your gonna have to get a small base die, the .3769 would have been perfect for you but it is what it is

L.Sherm

Silver $$ Contributor

Sound and looks like it likes some " grip " on the bullet but if your .230 loaded nk dia i would start with a .228.The gun shoots like a dream. Too much neck tension and running it through the sizer is so tight even with Imperial lube, I'm concerned about a case sticking in the die. Next firing I am going to neck size only. The main frustration is the inconsistent BTOs when seated. I didn't have that issue with the new full sized brass after using the .203 expander mandrel.

You can always test .001 smaller at a time after you have your powder, primer seating depth established.

lgwatson

Silver $$ Contributor

I neck sized a couple of cases with a .228 bushing (dummy rds) and they fit in the gun and were pretty snug and worked OK. I may turn .001 off of the neck and use the .228. I hope that solves the problem.Sound and looks like it likes some " grip " on the bullet but if your .230 loaded nk dia i would start with a .228.

You can always test .001 smaller at a time after you have your powder, primer seating depth established.

Similar threads

- Replies

- 7

- Views

- 2,138

- Replies

- 22

- Views

- 1,463

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.