I use a Micro100 boring bar but I’ll look into those.I’ve been loving these bars. They’re relatively inexpensive and easy to hone using a diamond knife sharpener.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

For the guys that pre-bore as much of the chamber as possible....

- Thread starter LVLAaron

- Start date

Dan-Schenk

Gold $$ Contributor

The one I use is about $30 and I just touch it up between uses with a cheap 1k grit diamond knife sharpening block. I’m a hobbiest for now but I’ve done 4 barrels using it for the crown and prebore.I use a Micro100 boring bar but I’ll look into those.

STS

Silver $$ Contributor

You can put the reamer in the bore if it's already dialed in. A center in the tailstock quill and you are all set. That's the way this simple minded hillbilly does it.Using a chuck makes sense... it's gonna be hard to get the reamer between centers if a barrel is in the chuck

Last edited:

LVLAaron

Gold $$ Contributor

I’ve been loving these bars. They’re relatively inexpensive and easy to hone using a diamond knife sharpener.

I spent maybe 60 or 80 dollars on a 6mm boring bar from Maritool. Good tool, but I broke it. Ended up with the bars I linked before from china/ebay. Half the price and they're my goto- especially for the larger bars.

I can do the trig, simple right triangle, but the graduations on the compound would only get close. You can set a dial indicator on the compound and run it against the TS quill for a set distance.Astonishing nobody can do the Trig.

Sorry, somebody already posted similar.I can do the trig, simple right triangle, but the graduations on the compound would only get close. You can set a dial indicator on the compound and run it against the TS quill for a set distance.

DaveTooley

Gold $$ Contributor

ARCTAN(0.06526/20) = 0.186955°

I didn't bother since my compound only has notches at 1° increments.

Even faster is do it the other way around. Magnetic base with the indicator on the side of the compound. Roll saddle 1" . Adjust angle till it matches the body taper. Example; 308 Win has a body taper of .00524" TPI per sideI can do the trig, simple right triangle, but the graduations on the compound would only get close. You can set a dial indicator on the compound and run it against the TS quill for a set distance.

ELR LVR

Silver $$ Contributor

"Common core math" killed itAstonishing nobody can do the Trig.

Last edited:

This.Common core math killed it

We had a new kid in the shop and he was flummoxed by fractions.

I remember learning fractions in the 3rd grade!

I have done that as well. The reason I dial on the chuck or quill, while moving the compound, is that it gives me a true and precise measurement. Not that moving the saddle introduces a lot of error, but it is a potential variable. Since I am cutting the taper with the compound, that is all I want to measure. Also, without a digital readout, I can still easily move the compound precisely 1 inch. I know I can use a dial gauge to measure carriage travel precisely, but gauging on the quill, or the chuck, from the compound, is just easier for me. Neither way is wrong and I don't think either of us is likely wrong either. WHEven faster is do it the other way around. Magnetic base with the indicator on the side of the compound. Roll saddle 1" . Adjust angle till it matches the body taper. Example; 308 Win has a body taper of .00524" TPI per side

Speak for yourself.Astonishing nobody can do the Trig.

I do step bore but if I need a taper, I use the Sine bar i built for the compound on two of the latest in my shop.

Lathes --- gd auto spell.Speak for yourself.

I do step bore but if I need a taper, I use the Sine bar i built for the compound on two of the latest in my shop.

Astonishing nobody can do the Trig.

ATAN(tpi/2) = angle per side

My 2 cents- Just cut a cylindrical pre-bore and put a little chamfer at the opening, then feed a little faster in the pre-bore section.

LVLAaron

Gold $$ Contributor

ATAN(tpi/2) = angle per side

My 2 cents- Just cut a cylindrical pre-bore and put a little chamfer at the opening, then feed a little faster in the pre-bore section.

That's more or less what I do. I pre-bore just past the neck diameter, then turn a "false" shoulder that matches the shoulder angle. I find this gets the reamer started with the least drama.

Do you use the same bar for crowning?

I have several of these. I use polished inserts. Excellent on stainless barrels for pre-bore work, crowns, etc.

I'm currently using solid carbide no insert bars and am looking for something that I can just swap an insert.

Guess I'm a bit puzzled by all the "saves time" responses.I just prebore to save time.

I just drill and pre-bore about an inch then run the reamer. Guessing you guys "saving time" are using a flush system, which means it literally takes just a few minutes to get to the depth where you need to start taking measurements.

I just don't see how with all the added time involved in the setup to taper-bore, it saves any time at all.

Probably why my wife calls me "contrary Mary"

LVLAaron

Gold $$ Contributor

Yep. Get cheap ass polished inserts in bulk from ebay as well. Even cheap polished inserts cut beautifully. Just take small bites and use a light oil.Do you use the same bar for crowning?

I'm currently using solid carbide no insert bars and am looking for something that I can just swap an insert.

LVLAaron

Gold $$ Contributor

Guess I'm a bit puzzled by all the "saves time" responses.

I just drill and pre-bore about an inch then run the reamer. Guessing you guys "saving time" are using a flush system, which means it literally takes just a few minutes to get to the depth where you need to start taking measurements.

I just don't see how with all the added time involved in the setup to taper-bore, it saves any time at all.

Probably why my wife calls me "contrary Mary"

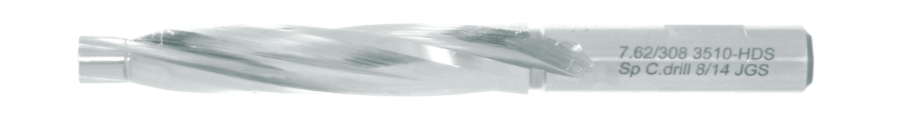

I'd say most people aren't using a flush system. But if you really want to talk about saving time... look at the JGS core drills (roughing reamer)

You can bore a chamber in about 1 minute.

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.