You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BULLET SORTING

- Thread starter 4xforfun

- Start date

jds holler

Gold $$ Contributor

I just came across a batch of 500 cheap 2nds that I had sorted into three different weight batches.

Life must have seemed longer back then. jd

jd

Life must have seemed longer back then.

Can you or your rifle shoot the difference? I tried it for a while and just like primers it wasn't worth the time.

4xforfun

Gold $$ Contributor

It might not make much of a difference. Uniforming primer pockets dosn't help much. Deburing flash holes doesn't help much. Weighing each powder charge to the kernal doesn't help much. Trimming the brass to exact same length doesn't matter much. Properly champhering the case mouths doesn't help much. Turning necks doesn't help much. Sorting cases by volume doesn't help much. Sorting brass by weight doesn't help much.Can you or your rifle shoot the difference? I tried it for a while and just like primers it wasn't worth the time.

But.....ADD UP THE TOTAL. Stack the results.

See where I am going with this?

Hmmm??? I think the answer depends on the particular shooting discipline one is involved in. For example: if you're shooting ELR there can be significant BC difference between lots due to differences in OAL's. Also, there can be significant differences in BTO's from lot to lot, especially where the seating stem makes contact resulting in different seating depths.I'm going to start bullet sorting. I haven't done it in a bunch of years, but what I did do was sort by bearing surface length. I segragate by every .001 of an inch.

When sorting by bearing surface length, would you have any problem with mixing different bullet lots?

6 years ago I ran a little test on some 168 SMK's that had a difference in BSL (Bearing Surface Length) of .067". There was a clear difference in velocities of ~35.5 fps as well as a shift in POI's of something like ~1/4 MOA as best as I could measure at the time (shot at 100 yds). Simply based on what I saw in my test, .001 doesn't seem likely to make any measurable difference, even at distance. Though, like with seating depths, I feel .003" might make a very small difference given how BSL can have an effect with the timing of blow-by as the bullet is being released. ¯\_(ツ)_/¯

4xforfun

Gold $$ Contributor

600/1000 BR . For now sorting 204 Vapor trails and 215 Berger Hybrid.Hmmm??? I think the answer depends on the particular shooting discipline one is involved in. For example: if you're shooting ELR there can be significant BC difference between lots due to differences in OAL's. Also, there can be significant differences in BTO's from lot to lot, especially where the seating stem makes contact resulting in different seating depths.

6 years ago I ran a little test on some 168 SMK's that had a difference in BSL (Bearing Surface Length) of .067". There was a clear difference in velocities of ~35.5 fps as well as a shift in POI's of something like ~1/4 MOA as best as I could measure at the time (shot at 100 yds). Simply based on what I saw in my test, .001 doesn't seem likely to make any measurable difference, even at distance. Though, like with seating depths, I feel .003" might make a very small difference given how BSL can have an effect with the timing of blow-by as the bullet is being released. ¯\_(ツ)_/¯

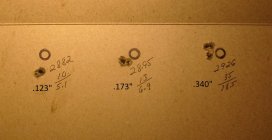

View attachment 1540332 View attachment 1540333

butchlambert

Site $$ Sponsor

No.It might not make much of a difference. Uniforming primer pockets dosn't help much. Deburing flash holes doesn't help much. Weighing each powder charge to the kernal doesn't help much. Trimming the brass to exact same length doesn't matter much. Properly champhering the case mouths doesn't help much. Turning necks doesn't help much. Sorting cases by volume doesn't help much. Sorting brass by weight doesn't help much.

But.....ADD UP THE TOTAL. Stack the results.

See where I am going with this?

Sorted these for a simple powder work up and no tuner involved.You guys....... OY!

I'll start thinking about this when I'm in the high .2s.

Meanwhile I'm taking pictures when I'm in the high. 3s.

It really don't take me that long. Ohhhhh.....The primers were sorted

also, as were the cases, and I took a pic !! Sad part about all this is,

The crowd i shoot with will still clean my clock.....LOL

Attachments

600/1000 BR . For now sorting 204 Vapor trails and 215 Berger Hybrid.

are you shooting 300WSM HG ?....I'm just getting one build and I'm planning on sorting 215's by OAL before trimming and pointing, I do sort my Roy's/Wheeler 103's by OAL into .002" batches then trim and point, I talked to few top custom bullet makers and they basically agreed that if you are gonna sort OAL seems to be the standard.

Northridge

Gold $$ Contributor

Them 204g vapors have produced some nice personal bests for a few guys out here at Deep Creek ..600/1000 BR . For now sorting 204 Vapor trails and 215 Berger Hybrid.

Shawn Williams

6BRA

Gold $$ Contributor

Perhaps the naysayers need to watch recently posted Jack Neary videos...and tell him he is wasting his time too. Along with Wayne Campbell who is doing a lot of Jack's work. Yea why bother? Some comments amaze me. 1/3 MOA and 1/4MOA...at 300 and 600, 1000 are not possible if you aren't going the extra mile.

butchlambert

Site $$ Sponsor

OK!Perhaps the naysayers need to watch recently posted Jack Neary videos...and tell him he is wasting his time too. Along with Wayne Campbell who is doing a lot of Jack's work. Yea why bother? Some comments amaze me. 1/3 MOA and 1/4MOA...at 300 and 600, 1000 are not possible if you aren't going the extra mile.

6BRA

Gold $$ Contributor

With this scientific approach, factory loaded LAPUA ammo is as good as it gets? Its more the Indian than the arrow? Just checking...I may sell off all my reloading equipment.

DaveTooley

Gold $$ Contributor

Variances in OAL is as much a function of lube, press stroke and jacket consistency. All of which shape the jacket flow forming the meplat. That's the reason for trimming/uniforming meplats. I measured the BC's of bullets from the same box that the BTO varied .020" . BC's were essentially the same. The meplat shape/uniformity has a much greater influence on BC. When I started selling meplat trimmers there were many times when customers purchased and used them during a 1K match. There was a noticeable improvement in the yaw in the bullet. Meplats would be centered in the bullet hole VS off center for untrimmed bullets.

One concern I would have is that different lots were likely made with different copper and lead. While the type and hardness are specified, you don’t always get exactly what you order. The swaging process should bring it all to about the same place but maybe one lot is slightly harder. If you’re really hunting to isolate differences, I’d keep lots separate.

Related note, I’d sort OAL too. I think OAL is more problematic for BC and consistency than bearing length.

Related note, I’d sort OAL too. I think OAL is more problematic for BC and consistency than bearing length.

jds holler

Gold $$ Contributor

OAL of a bullet is problematic, with a high degree of error occurring from the ogive to the tip. I've kind of decided that what I used to worry about as OAL of the cartridge is useless if I'm measuring from base to bullet tip.

I now use my rifle chamber and my bullet seating die as my comparators and seaters are drilled so as to exclude the tip contact. I'm still working on this, and I think that the validity of my system, will depend upon my bullet seater actually contacting the bullet (ogive) identically the same as the throat of my chamber. jd

I now use my rifle chamber and my bullet seating die as my comparators and seaters are drilled so as to exclude the tip contact. I'm still working on this, and I think that the validity of my system, will depend upon my bullet seater actually contacting the bullet (ogive) identically the same as the throat of my chamber. jd

I agree with what you are saying on bullet seating, but I don’t try to affect seating consistency by sorting bullets. I think neck prep is the big lever for that. I’m trying to limit bullet variances that change the BC and cause dispersion at distance when I sort bullets. Bullet experts have told me that the front half of the bullet changes the BC more than variations in the back half. I sort both, first by ogive to bullet base, then by OAL. OAL sorting appears to tighten vertical some at 1k. Sorting by ogive didn’t seem to do much but I keep trying it for periods of time to see if I can tease out some evidence it helps.OAL of a bullet is problematic, with a high degree of error occurring from the ogive to the tip. I've kind of decided that what I used to worry about as OAL of the cartridge is useless if I'm measuring from base to bullet tip.

I now use my rifle chamber and my bullet seating die as my comparators and seaters are drilled so as to exclude the tip contact. I'm still working on this, and I think that the validity of my system, will depend upon my bullet seater actually contacting the bullet (ogive) identically the same as the throat of my chamber. jd

I would do a sample secondary check.... If the base to Ogive come out the same I would measure the OAL of each. if they are close within .002 i think you would be good to go. I can tell you MY experience based on sorting thousands of 215's the two lots will be different, notiable differences in OAL. (lots purchased years appart).

Keep them separate until you can test on paper.

Trevor

Keep them separate until you can test on paper.

Trevor

Similar threads

- Replies

- 34

- Views

- 4,798

- Replies

- 2

- Views

- 1,105

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.