One big thing a CNC can do that you can't easly do on a manual lathe is transition from the bore part of the chanber to the lead with out a pause.More involved than most are doing is a big statement to make. Especially if you haven't spoke to most about the process as well.

Finishing with a boring bar, quite a few are doing them start to finish that way. I thought that his finish machining where it counted (leade) was with a Henrickson (probably spelled wrong there) reamer after he done all the work with the boring bar.

As far as CNC lathe? The two other people that own one are using it. CNC does not mean its going to be the greatest thing ever like a bunch of people think. Really all the CNC is going to produce over a guy with a good manual machine and machining practices is maybe faster production volume and maybe easier to do the feed rate variations for finish he talks about. Don't get me wrong, Jerry does quality work and uses the machines he has to do it with, but I would say he could do just as quality work with a manual machine too. I would bet his process for that manual machine would be different from the CNC/very similar to a lot of other guys on manual machines as well. May be wrong on that but I suspect. I doubt his expectations for finish product would change from a barrel done in the CNC vs done on a manual machine too. He would still expect his work to be competitive and capable of winning.

Tad

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What 22LR Reamer & Barrel

- Thread starter Edward Manning

- Start date

-

- Tags

- 22lr match

Greg@wfcustom

Gold $$ Contributor

They don’t, that’s the point!Greg,

Could you please explain what barrels have to do with ignition.

TKH

G

Last edited:

gunsandgunsmithing

M.Ezell

Exactly right. In truth, it's really hard to beat a reamer for this job, with any other process. Generally speaking, it's just the right tool for the job. Yes, I'm sure Jerry does a great job by whatever means he does it but using a boring bar to chamber is fraught with perils that are not so with a reamer. If I were gonna use a similar process, I'd try to rig a small ID grinder to the tool post and grind the last bit rather than cutting it. Just my 2 cents though.More involved than most are doing is a big statement to make. Especially if you haven't spoke to most about the process as well.

Finishing with a boring bar, quite a few are doing them start to finish that way. I thought that his finish machining where it counted (leade) was with a Henrickson (probably spelled wrong there) reamer after he done all the work with the boring bar.

As far as CNC lathe? The two other people that own one are using it. CNC does not mean its going to be the greatest thing ever like a bunch of people think. Really all the CNC is going to produce over a guy with a good manual machine and machining practices is maybe faster production volume and maybe easier to do the feed rate variations for finish he talks about. Don't get me wrong, Jerry does quality work and uses the machines he has to do it with, but I would say he could do just as quality work with a manual machine too. I would bet his process for that manual machine would be different from the CNC/very similar to a lot of other guys on manual machines as well. May be wrong on that but I suspect. I doubt his expectations for finish product would change from a barrel done in the CNC vs done on a manual machine too. He would still expect his work to be competitive and capable of winning.

Tad

G,They don’t, that’s the point!

G

You lost me with this statement. "Attention to detail and best practices don't care about the ignition system."

Please clarify your statement because it sounds like you are saying attention to detail and best practices aren't needed for the ignition system.

TKH

Didn't mean to get you worked up there Tad. My apoligies if I did. Do you recall the thread I mentioned over on RA? He mentioned you in the first sentenceMore involved than most are doing is a big statement to make. Especially if you haven't spoke to most about the process as well.

Finishing with a boring bar, quite a few are doing them start to finish that way. I thought that his finish machining where it counted (leade) was with a Henrickson (probably spelled wrong there) reamer after he done all the work with the boring bar.

As far as CNC lathe? The two other people that own one are using it. CNC does not mean its going to be the greatest thing ever like a bunch of people think. Really all the CNC is going to produce over a guy with a good manual machine and machining practices is maybe faster production volume and maybe easier to do the feed rate variations for finish he talks about. Don't get me wrong, Jerry does quality work and uses the machines he has to do it with, but I would say he could do just as quality work with a manual machine too. I would bet his process for that manual machine would be different from the CNC/very similar to a lot of other guys on manual machines as well. May be wrong on that but I suspect. I doubt his expectations for finish product would change from a barrel done in the CNC vs done on a manual machine too. He would still expect his work to be competitive and capable of winning.

Tad

Barrel chambering

I am responding to Tad's request on some discussion on this subject, specifically boring vs reaming. In the future, I am going to make a series of 3 to 5 minute videos showing the steps that I use to chamber a barrel. There will probably be 5 to 10 total videos showing each step. If they...

www.rimfireaccuracy.com

www.rimfireaccuracy.com

Maybe I should've clariified my statement when I said more than most. I wasn't referring to the Gorhams, Penrods, Davis, Langleys, etc. I was referring to the guys working on the old Southbend in their garage. Not trying to put the guys doing their own work down but I stand by my statement. Heck even I re-chambered a barrel on the lathe in our gunsmithing shop after my brother moved on to S. CO to teach gunsmithing. I think i did a pretty good job for a amateur messing around with no supervision but it was nothing like Stiller describes. Probably didn't look anything like it either. I guess I should've realized those who were describing chambering in posts above were over-simplifying their process

And I probably did misunderstand Jerry when he described his process. He did mention a Hendrickson reamer. After reading the thread I linked above it makes more sense now.

Last edited:

One thing I've learned is to have an open mind. Depending on equipment used and skillset there are a lot of different ways that work. I've been very fortunate to have a lot of great shooters put their trust in me and am extremely grateful to some of the guys I consider legends in the sport share with me the things they do.

To me the machining is fundamental. It's the rest of it that creates the separation. It doesn't matter what anybody tells you either of their methods if the equipment or you aren't up to the task.

I use a Hardinge HLV-H and a Mazak QT10 for barrel work. I now chamber most everything by boring on the Mazak. That means different things for different purposes though. There are no absolutes with it other than you better be confident in your setup.. There are things I do differently with bench guns vs precision field guns. What it does for me is it gets me a good starting point quickly and a really good finish on the leade. Shooting and inspecting the barrel tells whether it's right and what else may need to be done. Sometimes I use a reamer to make changes and sometimes it's rebored. I put a lot of emphasis on the shooting aspect of chambering. Some do and some don't but I feel it's of extreme importance. As Tad mentioned about the methods, I know I have expectations with either method of the same outcome. One just gets me there quicker.

I have been intentionally vague on some points but don't think that spending 120k on a machine and doing chambers with it is going to be all unicorns and rainbows. There are challenges to it you never see with a reamer. You better keep check of all those dimensions you have control over and must be confident in the setup or things can go south quickly. It was a long transition for me to switch and a lot of testing but I'd now have a hard time going back.

To directly give my opinion of the OP's question, Pick a reamer as Tad or Tony previously suggested and do it correctly and good ammo of either kind will shoot.

To me the machining is fundamental. It's the rest of it that creates the separation. It doesn't matter what anybody tells you either of their methods if the equipment or you aren't up to the task.

I use a Hardinge HLV-H and a Mazak QT10 for barrel work. I now chamber most everything by boring on the Mazak. That means different things for different purposes though. There are no absolutes with it other than you better be confident in your setup.. There are things I do differently with bench guns vs precision field guns. What it does for me is it gets me a good starting point quickly and a really good finish on the leade. Shooting and inspecting the barrel tells whether it's right and what else may need to be done. Sometimes I use a reamer to make changes and sometimes it's rebored. I put a lot of emphasis on the shooting aspect of chambering. Some do and some don't but I feel it's of extreme importance. As Tad mentioned about the methods, I know I have expectations with either method of the same outcome. One just gets me there quicker.

I have been intentionally vague on some points but don't think that spending 120k on a machine and doing chambers with it is going to be all unicorns and rainbows. There are challenges to it you never see with a reamer. You better keep check of all those dimensions you have control over and must be confident in the setup or things can go south quickly. It was a long transition for me to switch and a lot of testing but I'd now have a hard time going back.

To directly give my opinion of the OP's question, Pick a reamer as Tad or Tony previously suggested and do it correctly and good ammo of either kind will shoot.

Last edited:

Greg@wfcustom

Gold $$ Contributor

I’ll try this slowly…G,

You lost me with this statement. "Attention to detail and best practices don't care about the ignition system."

Please clarify your statement because it sounds like you are saying attention to detail and best practices aren't needed for the ignition system.

TKH

The piece of steel doesn’t care what type of ignition the cartridge uses. The point I was trying to make is the process is essentially the same.

As I also tried to point out, there is a different finish required for lead vs jacketed.

I’m out now you, you guys can carry on with the Voodo and Black Magic.

G

G,I’ll try this slowly…

The piece of steel doesn’t care what type of ignition the cartridge uses. The point I was trying to make is the process is essentially the same.

As I also tried to point out, there is a different finish required for lead vs jacketed.

I’m out now you, you guys can carry on with the Voodo and Black Magic.

G

I don’t believe any innate object cares about anything.

If English is your second language I understand your problem conveying your ideas. Even your slow post makes little sense. With this being a shooters forum and a lot of information is technical in nature, perhaps you have made the best decision.

Good bye.

TKH

TRSR8

Silver $$ Contributor

Friend Ezell, I truly love some of your comments, such an air of authority.Exactly right. In truth, it's really hard to beat a reamer for this job, with any other process. Generally speaking, it's just the right tool for the job. Yes, I'm sure Jerry does a great job by whatever means he does it but using a boring bar to chamber is fraught with perils that are not so with a reamer. If I were gonna use a similar process, I'd try to rig a small ID grinder to the tool post and grind the last bit rather than cutting it. Just my 2 cents though.

I’ve only been following the sport for 30 odd years, but it begs the question given all the expert advice.

Have you ever built a RFBR rifle for anybody that ever won anything to speak of, that would include yourself of course?

Thanks in advance for any input.

Last edited:

Slow night of pot-stirring, and impressing yourself?G,

You lost me with this statement. "Attention to detail and best practices don't care about the ignition system."

Please clarify your statement because it sounds like you are saying attention to detail and best practices aren't needed for the ignition system.

TKH

Hi-NV Shooter

Gold $$ Contributor

Hi Tad,It really is not anything special. Dial it in by one of the accepted methods, pick a pilot, and float the reamer in to desired depth. Double check your work and move on to the finishing if desired. It is more attention to detail than the average high volume job shop guy normally has to deal with but nothing that anyone that has the right equipment and a little patients can't handle. The straightness to the bore is much more important than anything else.

To the OP, I prefer a 2.0 degree leade and a 0.2250" straight body but its not the end all be all. In reality a reamer between 1.5 to 2.0 degree leade with a body diameter between 0.2250" - 0.2260" will put you in a good place. There are winning examples outside of these dimensions but the vast majority will fall in that range for RFBR. The biggest decision you will have to make is in how much engraving you want to use.

Tad

How much engraving do you like to see? do you use a different amount depending on the ammo or you use a constant regardless.

Lee

Perhaps you can impress me even more by explaining what that gibberish was suppose to mean.Slow night of pot-stirring, and impressing yourself?

TKH

What part of what I stated can't you quite understand?Perhaps you can impress me even more by explaining what that gibberish was suppose to mean.

TKH

Your condescention and feeble criticism of other members is boring and contrived.

Is that clear enough?

What part of what I stated can't you quite understand?

Your condescention and feeble criticism of other members is boring and contrived.

Is that clear enough?

I certainly understood your belittling and derogatory comment.

What I didn't understand was in my first post.

"Attention to detail and best practices don't care about the ignition system."

It is my belief ignition is dependent upon attention to detail and best practices, so I asked for clarification.

If you or G sees it differently, we can debate it.

But here is the follow up from G.

"The piece of steel doesn’t care what type of ignition the cartridge uses". I took this as a flippant response.

I was challenging his comment not belittling his thoughts. If you feel I was being condescending, so be it.

TKH

What I didn't understand was in my first post.

"Attention to detail and best practices don't care about the ignition system."

It is my belief ignition is dependent upon attention to detail and best practices, so I asked for clarification.

If you or G sees it differently, we can debate it.

But here is the follow up from G.

"The piece of steel doesn’t care what type of ignition the cartridge uses". I took this as a flippant response.

I was challenging his comment not belittling his thoughts. If you feel I was being condescending, so be it.

TKH

My "derogatory comment" is a standard retort to self-impressed people that already know the answers to their thinly veiled questions.I certainly understood your belittling and derogatory comment.

What I didn't understand was in my first post.

"Attention to detail and best practices don't care about the ignition system."

It is my belief ignition is dependent upon attention to detail and best practices, so I asked for clarification.

If you or G sees it differently, we can debate it.

But here is the follow up from G.

"The piece of steel doesn’t care what type of ignition the cartridge uses". I took this as a flippant response.

I was challenging his comment not belittling his thoughts. If you feel I was being condescending, so be it.

TKH

What you consider "belittling", most members consider exactly what you deserve.

Alex Wheeler

Site $$ Sponsor

Having not used 1000s of rf barrels like I have cf barrels I dont have strong opions yet. But I am starting to gain a preference for the 8 groove Mullerworks because of how they have been slugging. Just like with cf my preferences can and will if I see changes in the products.what 22LR reamer would you choose for Lapua and also what one for Eley and which Barrel manufacturer. I have a 2500X action

Thanks

linekin

Silver $$ Contributor

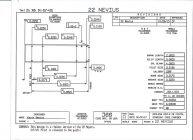

Below are some reamer specs you've likely seen. Of these I've used/tried the Freeland, Lilja, & PTG Match.. They all had solid pilots & a belt/stop so was limited to how deep I could go. Of which I felt the PTG shot the best, for whatever reason.what 22LR reamer would you choose for Lapua and also what one for Eley and which Barrel manufacturer. I have a 2500X action

Thanks

I've also attached the Nevius but cannot find a Calfee reamer print but believe its straight sided .225 or .2255

Since I've sourced a JGS Nevius, no belt, live pilot & Calfee spiral fluted, no belt, live pilot. Reason for both is to prove to myself if the different leade angles or chamber depths made a significant difference. I can not see any personally.

The latter 2 I feel like shoot the best, albeit with the Nevius I'm chambered deep(.035 engraving) & the Calfee I have .090 I can not prove to myself either is better than tthe other for either ammo. They both seem to shoot both very well.

I would recommend getting a non belted, live pilot reamer of your choice & & set of bushings for same.

The Nevius print

Last edited:

0.135" - 0.145" stick out dependent on rifiling pattern, bore dimensions, and leade angle. I do not change this based on ammo brand. I want all I can get without running into issues late into a card with pretty much any lot. A person may get away with as much as 0.150" stick out or a tick more at times with certain combinations but it typically turns into to much from what I have seen. People like you have success with minimal engraving but it is just not what I found to work best for our program.Hi Tad,

How much engraving do you like to see? do you use a different amount depending on the ammo or you use a constant regardless.

Lee

Maybe I should've clariified my statement when I said more than most. I wasn't referring to the Gorhams, Penrods, Davis, Langleys, etc. I was referring to the guys working on the old Southbend in their garage. Not trying to put the guys doing their own work down but I stand by my statement. Heck even I re-chambered a barrel on the lathe in our gunsmithing shop after my brother moved on to S. CO to teach gunsmithing. I think i did a pretty good job for a amateur messing around with no supervision but it was nothing like Stiller describes. Probably didn't look anything like it either. I guess I should've realized those who were describing chambering in posts above were over-simplifying their process

I have had the pleasure to do work behind Gorham, Davis, Langley, Wilkinson, and a few others where I was able to look at their work and been around plenty of Penrod's. They do fine work but they are far from the only people capable of competitive work. They would tell you this themselves. I have also had the pleasure of seeing work first hand from less cited smiths such as Kerley, Halcomb, James Carroll, and others with their work being just as fine using those old south bends or similar in their garage. Matter of fact, I do not think it would be a stretch to say that its probably been just as many or more competitive barrels spun up on a south bend or similar such as the old stand by Heavy 10. This business that a certain smith must be anointed to do competitive work is perpetuated way to often and usually comes from people that have no experience in the work. Pride in your smith is a great thing and something that should be shown, but claiming they are the only place to get competitive equipment is not so great. Good machine work comes down to the person knowing their machine and how to operate it with the appropriate goals and targets in mind.

Tad

Similar threads

- Replies

- 4

- Views

- 487

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.