This is a heck of a rabbit hole.

My 2 regularly-shot rifles are in 6.5 CM and 223 Rem.

The 6.5 with annealed-on-every-firing Lapua brass is boringly consistent, SD under 10 fps is easy to get. Very low neck tension judging by the effort required at the press handle.

The 223 needs more neck tension, and even then it's a struggle.

My experience has been that as the brass ages and hardens, you need less neck tension. The harder brass grips the bullet more tightly than when it was new. This becomes problematic, since you can't be sure how much tension you'll have til you seat the bullet.

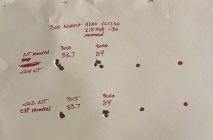

Even then, let's say you can quantify how much pressure it took to seat 25 rounds. If you have any significant difference between them, what do you do? Sort them into 3 groups? "Probably slower", "average", and "probably faster"?

At short range, it's not as critical. As you stretch things out, if your neck tension is inconsistent enough to affect combustion you're going to get vertical stringing. I know this from experience.

Neck tension can be measured 2 ways. The first is as a purely static physical dimension, 2 thou for example. This isn't a great way to operate, because it doesn't take into account brass condition, such as hardness, inside neck surface finish, etc.

The second way is much more relevant. It is a measure of how much pressure is required inside the case before the bullet starts to move. Realistically, you can only measure that by knowing how much force it took to seat the bullet, and that's assuming you don't have any cold welding between the bullet and the brass.

This all assumes your primer strength and powder charges are identical, etc.

I believe the reason a lightly jammed bullet in a low neck tension load leads to very consistent velocities is because pressure has a chance to build before the bullet can move, and it's the same every time.

That approach isn't everyone's cup of tea, including me. I want to be sure I can eject a loaded round without leaving a bullet stuck in the lands.

Like I said earlier, a rabbit hole. If you have a cartridge that's tolerant of annealing, there's a good reason annealing is so popular. You can "reset" your neck condition to zero at every firing.

If you have a cartridge that needs more neck tension to operate well, then you might have to get creative to achieve that goal.