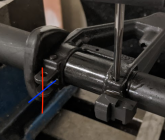

How do you install a new AR front sight on a barrel thats already drilled for taper pins?

The new sight doesn't have the holes so how can you drill and line up the holes? Original sight is not available and used ones may not line up correctly.

The new sight doesn't have the holes so how can you drill and line up the holes? Original sight is not available and used ones may not line up correctly.