You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Resizing Brass for 35 Rem?

- Thread starter Soloshotfirst

- Start date

joshb

Gold $$ Contributor

Ok! Just PM me your address and I’ll send them when your Gold Contributor banner goes up.Yes, just joined, funny enough, it was because I saw another member on here selling the Lee Loader for 35 Rem, (which I am so happy they sold to a fresh new account such as myself haha) which I had been looking for, for awhile now, for quick reloads to test out different recipes, instead of setting up my press.

That sounds like a good deal to me! I just got my first Marlin 336 in .35 Rem in February, which also was kind of an accident, as I initially bid on it thinking it was a 30-30, ended up winning, not expecting to, then they ended up telling me they had labeled it wrong and it was actually a .35 Rem, which I was happy to have as well, love me some lever action!

Josh

Last edited:

jackieschmidt

Gold $$ Contributor

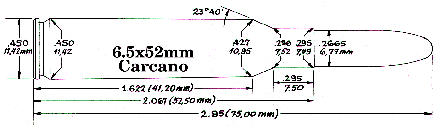

Just going by the print dimensions at the Web, you would get a pretty severe case expansion with the Carcano.View attachment 1387801

Here is a dimension drawing of the Carcano for reference and comparison to the .35 Remington.

PM incoming! I'm glad to have stumbled upon this community! From what I've been reading, it seems like resizing brass is beyond my capabilities at this point haha.Ok! Just PM me your address and I’ll send them when your Gold Contributor banner goes up.

Josh

I knew a old guy that had a model 8 with a pocket knife tied with string to the barrel to dig cases out of the chamber. Doug

Primer would probably have severe blow by and fall right out onJust going by the print dimensions at the Web, you would get a pretty severe case expansion with the Carcano.

opening the bolt.

I know it's been done by squeezing down .308 brass, but besides

having to machine the rim, the primer pocket would be in question.

There are sites that sell once fired range brass. Put google to work.

Probably had a broken extractor. One of the Model 8 or 81 Remington's we have/had broken an extractor.I knew a old guy that had a model 8 with a pocket knife tied with string to the barrel to dig cases out of the chamber. Doug

Because the Remington Model 8 has a box magazine I use a pointed bullet. I bought a bag of 500 Remington 200 grain bullets from Midway.

We've found the Model 8 35 Remington to be quite accurate, considering the two-piece stock and the fact that everything moves once it goes off.

butchlambert

Site $$ Sponsor

I just looked in my old cartridge drawer and found an old Peters box with 18 factory 30Rem rounds with 170gr. hollow points and a box with 14 or so pieces of 25 Rem brass.

If ya have a lathe and collets 35 Rem are fairly easy to make out of 308...I just did it. Mill to length in your Bridgeport. In your lathe with collets Cut the solid head down to print deepen the extractor groove..

Blend and FL size in your 35 Remington die perfect. Made 30 Remington out of 30-30 for a friend turn rimed to rimless with an extractor groove. 8.6 blackout out of 30-06, 308, 25-06, 270, etc. And the larger challenge make 308 into 6mm ARC. And for kicks I have 308 win cases that will take shotgun primers ...so in light loads...a 308 will take any primer available...rifle, pistol, large or small and now your shotgun primers too, and accurate with subs and Trailboss.

Almost no limit as to what you can do...like machine your own subsonic copper bullets, slit the hollow point with a slitting saw...and test results. Too much fun... 30 mauser pistol bullets totally expand in 300 Blackout at 1000 fps when you deep hollow point them in the lathe.

Blend and FL size in your 35 Remington die perfect. Made 30 Remington out of 30-30 for a friend turn rimed to rimless with an extractor groove. 8.6 blackout out of 30-06, 308, 25-06, 270, etc. And the larger challenge make 308 into 6mm ARC. And for kicks I have 308 win cases that will take shotgun primers ...so in light loads...a 308 will take any primer available...rifle, pistol, large or small and now your shotgun primers too, and accurate with subs and Trailboss.

Almost no limit as to what you can do...like machine your own subsonic copper bullets, slit the hollow point with a slitting saw...and test results. Too much fun... 30 mauser pistol bullets totally expand in 300 Blackout at 1000 fps when you deep hollow point them in the lathe.

Tried to improve the 308Win to 35 Remington for the average guy...

Came up with this, ...trim 308 to 35 Rem length, deburr, expand 308 neck to 33Cal, then 35 Cal.

Lube cases with Lee Resizing lube. Apply a dab of lube in the hand rub palms together, grab 5 cases roll in hands the lube is applied evenly rather quickly. Next you have 2 Full Length dies a Lee 7X64 Brenneke, & 44 Mag "carbide" pistol die You can go either to the Lee 44 Mag pistol carbide all the way down to the shell holder with the Lee Resizing lube applied or the FL 7X64 Brenneke die..either one first seems work. The lubed 44 Mag die works slick...but to get all the way down the head I had to take .020" off the shell holder and take the carbide ring out of the Lee die and face turn some the steel off about 0.060" then use the diamond wheel to grind off most of the large champher on the carbide sizing ring...reinstall inside the die recess with red loctite. Becarefull not to bump the carbide with the shell holder...it's brittle...the exposed carbide ring in the die will now fully bring the case head into print with out leaving the small oversized ring on the case head (and looks perfect) ...which can be easily filed in without messing with the carbide ring....because the .470" 308 case head rim has to be turned or filled down slightly to .460" & file a slight 45° champher on the rim while your at it ..trim to length again...then lube and run through your 35 Remington FL die to fit your chamber...or the Wilson case gauge.

You may not have to recut the extractor groove as most 308s seem to be on the deep side, coming within .002" (some) (to mostly) .004" oversize for the 35 Remington extractor groove diameter. Making the extractor slightly proud, out of position...will it cause any interferences...You'll have to check..to see if the extractor grove must be machined or filed deeper for your rifle...but its very close, as is.

These cases will have 1.5 gr less capacity than factory 35 Remington cases so adjust the maximim charges down slightly.

This goes faster than explaining it, once setup, but in case you can't find any 35 Remington brass, you can make it from 308 Win...if necessary.

Came up with this, ...trim 308 to 35 Rem length, deburr, expand 308 neck to 33Cal, then 35 Cal.

Lube cases with Lee Resizing lube. Apply a dab of lube in the hand rub palms together, grab 5 cases roll in hands the lube is applied evenly rather quickly. Next you have 2 Full Length dies a Lee 7X64 Brenneke, & 44 Mag "carbide" pistol die You can go either to the Lee 44 Mag pistol carbide all the way down to the shell holder with the Lee Resizing lube applied or the FL 7X64 Brenneke die..either one first seems work. The lubed 44 Mag die works slick...but to get all the way down the head I had to take .020" off the shell holder and take the carbide ring out of the Lee die and face turn some the steel off about 0.060" then use the diamond wheel to grind off most of the large champher on the carbide sizing ring...reinstall inside the die recess with red loctite. Becarefull not to bump the carbide with the shell holder...it's brittle...the exposed carbide ring in the die will now fully bring the case head into print with out leaving the small oversized ring on the case head (and looks perfect) ...which can be easily filed in without messing with the carbide ring....because the .470" 308 case head rim has to be turned or filled down slightly to .460" & file a slight 45° champher on the rim while your at it ..trim to length again...then lube and run through your 35 Remington FL die to fit your chamber...or the Wilson case gauge.

You may not have to recut the extractor groove as most 308s seem to be on the deep side, coming within .002" (some) (to mostly) .004" oversize for the 35 Remington extractor groove diameter. Making the extractor slightly proud, out of position...will it cause any interferences...You'll have to check..to see if the extractor grove must be machined or filed deeper for your rifle...but its very close, as is.

These cases will have 1.5 gr less capacity than factory 35 Remington cases so adjust the maximim charges down slightly.

This goes faster than explaining it, once setup, but in case you can't find any 35 Remington brass, you can make it from 308 Win...if necessary.

Similar threads

- Replies

- 52

- Views

- 5,099

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.