You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

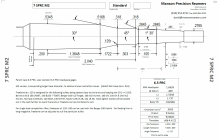

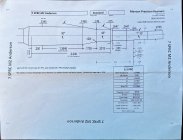

Reading manson prints... dumb question 7-6.5 PRC

- Thread starter LVLAaron

- Start date

LVLAaron

Gold $$ Contributor

.5345 is the .200 line

Thanks. I kind of interpreted that from their notes compared to the saami drawing but the nomenclature was confusing. Appreciate the sanity check.

LVLAaron

Gold $$ Contributor

The print was just a starting point. There will be enough freebore for everyone to have a good time. I'm altering the freebore and neck dimensions.Don't seem to be enough freebore.

Dusty Stevens

Shiner

Put that freebore in last. Then everybody can be happyThe print was just a starting point. There will be enough freebore for everyone to have a good time. I'm altering the freebore and neck dimensions.

DaveTooley

Gold $$ Contributor

I'd spec FB diameter @ .2847" -.0000" +.0002"

YMMV

YMMV

LVLAaron

Gold $$ Contributor

I'd spec FB diameter @ .2847" -.0000" +.0002"

YMMV

Why? cartridge design isn't my strong point, unless it's an FTR reamer.

DaveTooley

Gold $$ Contributor

I have never been a fan of overly tight FB on larger cases. Carbon can and will build up. Barrels are not always on size leading to very shallow lands coming back to the neck. That's assuming you have a perfectly concentric chamber with no reamer wear and with a reamer that is not undersize. And the bottom line is it doesn't hurt accuracy but can add variables. I designed the reamers for USSOCOM for the new sniper rifle. I put in larger FB diameters for obvious reasons. Lack of maintenance mainly. There was an uproar as it went against conventional wisdom. The accuracy barrels I did for ammo development averaged 1/2MOA at 1K yards. Nuff said.

I have never been a fan of overly tight FB on larger cases. Carbon can and will build up. Barrels are not always on size leading to very shallow lands coming back to the neck. That's assuming you have a perfectly concentric chamber with no reamer wear and with a reamer that is not undersize. And the bottom line is it doesn't hurt accuracy but can add variables. I designed the reamers for USSOCOM for the new sniper rifle. I put in larger FB diameters for obvious reasons. Lack of maintenance mainly. There was an uproar as it went against conventional wisdom. The accuracy barrels I did for ammo development averaged 1/2MOA at 1K yards. Nuff said.

Come on Dave, you and I both know that no one that shoots our favorite discipline--the one you designed the MBR for--is happy with 1/2 MOA groups at 1k........unless we are talking 10-shot groups. And all rifles spoken of on the internet have to be LRBR accurate at 1k...................

DaveTooley

Gold $$ Contributor

They were 10 shot groups in the testing. As one gentleman said. "It didn't hurt anything"Come on Dave, you and I both know that no one that shoots our favorite discipline--the one you designed the MBR for--is happy with 1/2 MOA groups at 1k........unless we are talking 10-shot groups. And all rifles spoken of on the internet have to be LRBR accurate at 1k...................

Alex Wheeler

Site $$ Sponsor

Dave, it helped accuracy whether they know it or not.

DaveTooley

Gold $$ Contributor

Be sure to spell out the tolerances of the FB -.0000" +.0002"

Mark out Dim A and all those other pesky little numbers. They're for the CNC grinder doing SAAMI stuff.

Freebore of .240 is fine.

LVLAaron

Gold $$ Contributor

Be sure to spell out the tolerances of the FB -.0000" +.0002"

Mark out Dim A and all those other pesky little numbers. They're for the CNC grinder doing SAAMI stuff.

Will do. I'll add the tolerance and finalize the other stuff on the phone with them!

Similar threads

- Replies

- 2

- Views

- 1,661

- Replies

- 2

- Views

- 1,832

- Replies

- 4

- Views

- 429

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.