TTE

Gold $$ Contributor

Forming 6.5 06AI from Lapua 06 brass.

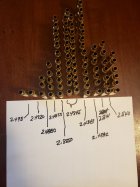

Brass annealed, used 06fl, 280fl, 270fl and 6.5 neck dies. With previous advise, no expanders in dies. All cases had a false shoulder.

Before COW fire forming

After fire forming

Max case length is 2.494.

The majority of the cases are what I assume is trim to length (2.484) or shorter. Is this normal ? Which of these cases are no longer useable ? Am I doing something incorrectly ? Why are the cases so different in length ?

Would appreciate any help and adivse.

Thanks

Brass annealed, used 06fl, 280fl, 270fl and 6.5 neck dies. With previous advise, no expanders in dies. All cases had a false shoulder.

Before COW fire forming

After fire forming

Max case length is 2.494.

The majority of the cases are what I assume is trim to length (2.484) or shorter. Is this normal ? Which of these cases are no longer useable ? Am I doing something incorrectly ? Why are the cases so different in length ?

Would appreciate any help and adivse.

Thanks