Has anyone found a method to tune Quickload for gas guns such as AR15s? I am thinking of the effect of gas bleed to operate the bolt on chamber pressure and muzzle velocity.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quickload and Gas Guns?

- Thread starter 243Mendoza

- Start date

I've been using QuickLoad for over a decade on my M1A rifles and now my AR .308. I don't understand what your remark about the effect of gas bleed means. The gas system uses such a small amount of the total gas (and it's not even diverted until the bullet is within a few microseconds of exiting the muzzle) that there is very little effect on the muzzle velocity.Has anyone found a method to tune Quickload for gas guns such as AR15s? I am thinking of the effect of gas bleed to operate the bolt on chamber pressure and muzzle velocity.

I don't remember exactly the velocity differences (I need to look at the Labradar records) but the difference is around 100fps between Quickload and Labradar readings for the 77gr bullets and H335 for 18" barrel.

I don't remember exactly the velocity differences (I need to look at the Labradar records) but the difference is around 100fps between Quickload and Labradar readings for the 77gr bullets and H335 for 18" barrel.

Are you just using QuickLoad's default burn rate?

Or have you made adjustments for differences in burn rate as one might get from lot to lot?

Ned Ludd

Silver $$ Contributor

The powder burn rate (Ba) files in Quickload are generic values, typically determined in an enclosed system that may have a very limited relationship to what actually occurs during combustion in a cartridge/rifle chamber. In actual use, powder burn rates are dependent on temperature, pressure, priming source, and to a lesser extent, the shape of the cartridge. Thus, powder burn rates can vary between loadings in different cartridges, when using different bullets, when using different primers, or even between different Lots of the same powder. Occasionally, the variance between the powder burn rate observed by the reloader and the value provided in the Quickload pull-down menu can vary substantially. Quickload cannot feasibly provide accurate burn rates for every possible scenario in which a reloader might use a given powder. So they include a generic measured value for a fairly wide range of commonly-used powders, then provide the user with the tools to modify the burn rate value in accordance with their own direct measurements.I don't remember exactly the velocity differences (I need to look at the Labradar records) but the difference is around 100fps between Quickload and Labradar readings for the 77gr bullets and H335 for 18" barrel.

A relatively simple way to "calibrate" Quickload to your specific setup is to load about 10 rounds using a slightly reduced powder charge for safety reasons. There are different ways to ensure using a safe charge such as picking a charge weight at the low end of the range from a reloading manual, or by using the factory preset burn rate in Quickload to estimate a charge weight that predicts a safe pressure and velocity, then decreasing that estimated charge weight by an additional 2 to 3%. You then determine the actual average velocity of those loaded rounds (i.e. measure velocity for a known charge weight, at a defined ambient temperature).

Once home, you plug in all the appropriate measurements (barrel length, bullet OAL, COAL, case length, case volume, charge weight, temperature) into the Quickload file. These are all values that you should be able to measure directly and accurately, and it is essential that these inputs are accurate in order to obtain reliable predictions from the software. If the predicted velocity does not exactly match your measured average velocity, activate the burn rate "write" feature that will allow you to adjust the preset burn rate (Ba) up or down until the predicted velocity exactly matches your average measured velocity.

Once this is done, you have "calibrated" the program to your specific setup and within a certain charge weight range, the predictions should be reasonably accurate. It is important to note that the farther you have to adjust the charge weight from the "calibration" value to the charge weight used in a final optimized load, the farther off the pressure/velocity predictions are likely to be. This is because the program treats certain responses as being essentially linear, when in reality they are not linear. For that reason, I adjust the burn rate value in Quickload every time I test, including any changes to the inputs such as temperature, COAL, measured average velocity etc., and save it as a new file so the original "calibration" file is not overwritten. Usually, just changing the date in the original filename is sufficient. Then you will always have, in effect, a timeline of the load development process in the form of successive Quickload files. This process is also useful for recording and assessing routine and expected load changes, such as a brand new barrel "speeding up" over the first couple hundred rounds or the effect of temperature on pressure/velocity with a given powder as the seasons change. It can also be very useful for identifying potential problems, such as excessive carbon fouling in the throat, which tends to increase pressure over time, or anything else that may unexpectedly cause the characteristics of the load to deviate unexpectedly. Because you have the program, routine recording and updating of files can be a useful habit to develop. As I have learned the hard way, the one piece of data you are almost guaranteed to want or need at some future date is the one you didn't record. Good luck with it!

Last edited:

Thanks for taking the time for a comprehensive response.The powder burn rate (Ba) files in Quickload are generic values, typically determined in an enclosed system that may have a very limited relationship to what actually occurs during combustion in a cartridge/rifle chamber. In actual use, powder burn rates are dependent on temperature, pressure, priming source, and to a lesser extent, the shape of the cartridge. Thus, powder burn rates can vary between loadings in different cartridges, when using different bullets, when using different primers, or even between different Lots of the same powder. Occasionally, the variance between the powder burn rate observed by the reloader and the value provided in the Quickload pull-down menu can vary substantially. Quickload cannot feasibly provide accurate burn rates for every possible scenario in which a reloader might use a given powder. So they include a generic measured value for a fairly wide range of commonly-used powders, then provide the user with the tools to modify the burn rate value in accordance with their own direct measurements.

A relatively simple way to "calibrate" Quickload to your specific setup is to load about 10 rounds using a slightly reduced powder charge for safety reasons. There are different ways to ensure using a safe charge such as picking a charge weight at the low end of the range from a reloading manual, or by using the factory preset burn rate in Quickload to estimate a charge weight that predicts a safe pressure and velocity, then decreasing that estimated charge weight by an additional 2 to 3%. You then determine the actual average velocity of those loaded rounds (i.e. measure velocity for a known charge weight, at a defined ambient temperature).

Once home, you plug in all the appropriate measurements (barrel length, bullet OAL, COAL, case length, case volume, charge weight, temperature) into the Quickload file. These are all values that you should be able to measure directly and accurately, and it is essential that these inputs are accurate in order to obtain reliable predictions from the software. If the predicted velocity does not exactly match your measured average velocity, activate the burn rate "write" feature that will allow you to adjust the preset burn rate (Ba) up or down until the predicted velocity exactly matches your average measured velocity.

Once this is done, you have "calibrated" the program to your specific setup and within a certain charge weight range, the predictions should be reasonably accurate. It is important to note that the farther you have to adjust the charge weight from the "calibration" value to the charge weight used in a final optimized load, the farther off the pressure/velocity predictions are likely to be. This is because the program treats certain responses as being essentially linear, when in reality they are not linear. For that reason, I adjust the burn rate value in Quickload every time I test, including any changes to the inputs such as temperature, COAL, measured average velocity etc., and save it as a new file so the original "calibration" file is not overwritten. Usually, just changing the date in the original filename is sufficient. Then you will always have, in effect, a timeline of the load development process in the form of successive Quickload files. This process is also useful for recording and assessing routine and expected load changes, such as a brand new barrel "speeding up" over the first couple hundred rounds or the effect of temperature on pressure/velocity with a given powder as the seasons change. It can also be very useful for identifying potential problems, such as excessive carbon fouling in the throat, which tends to increase pressure over time, or anything else that may unexpectedly cause the characteristics of the load to deviate unexpectedly. Because you have the program, routine recording and updating of files can be a useful habit to develop. As I have learned the hard way, the one piece of data you are almost guaranteed to want or need at some future date is the one you didn't record. Good luck with it!

I am hesitant to change Ba since I do not know the maximum amount of change that is reasonable.

Also I am unaware that temperature is an input! Is is ambient air temp or chamber temp?

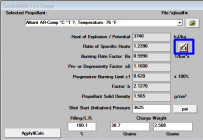

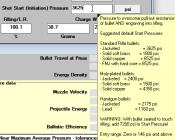

Reading the instructions that comes with the software will probably help. You can change several inputs to help adjust the predicted velocity to match the measured velocity.

Case capacity

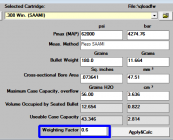

Weighting factor

Powder burning rate factor

Shot start pressure

Ambient temperature

All of these factors can be adjusted and if you read the manual you will find recommendations of what to adjust first.

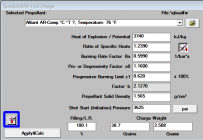

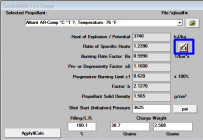

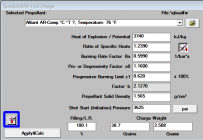

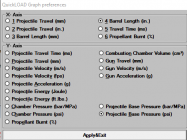

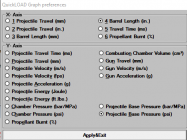

The temperature adjustment is enabled when you click on the small icon to the right of the Ratio of specific heats.

After you click the icon a temperature adjustment icon will appear above the Apply&Calc button

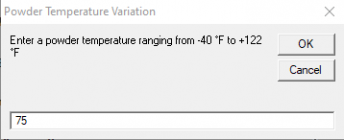

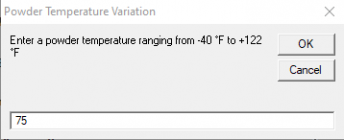

After you click on the Temperature icon this window will appear

It's entitled Powder Temperature Variation so the software expects you use the powder temperature but in most situations your powder will be the same temperature as the ambient temperature and it's pretty hard to actually measure the temperature of the powder.

There is no information that I've found that defines a limit to the Ba adjustment but I don't like to change my numbers by more than .1, most often I can get good results with far less of a change, more like plus or minus .02.

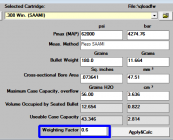

Before I start changing the Ba value (which can vary from lot to lot of the same powder) I make sure that I use the proper Shot Start Pressure value based on the recommendations that the software displays in a popup if you hold the your cursor over the value for a second or two.

The Weighting Factor is another value that I change before I start adjusting the Ba value. This represents the amount of powder that follows the base of the bullet. Most ballisticians use .5 (50% of the powder charge) as the standard value. You can change this up or down a couple tenths (.4 to .6). This value is just a guess and it is controlled by the case shape and powder characteristics, I don't know of any standard that specifies what this value should be in relation to the case or powder so it's just a guess.

When you decide to change the Ba value some people recommend changing the case capacity instead. I wont change the case capacity by more than half a grain if I've measured it.

A lot of these adjustments are going to be based on what input data you feel has a better chance of being correct. For example, if you have to choose whether to change the Ba value or the case capacity I'd base it on whether I know one or the other for a fact. If I've actually measured the case capacity (in accordance with the software manual's instructions) the I'd probably change the Ba value since I couldn't measure it.

Case capacity

Weighting factor

Powder burning rate factor

Shot start pressure

Ambient temperature

All of these factors can be adjusted and if you read the manual you will find recommendations of what to adjust first.

The temperature adjustment is enabled when you click on the small icon to the right of the Ratio of specific heats.

After you click the icon a temperature adjustment icon will appear above the Apply&Calc button

After you click on the Temperature icon this window will appear

It's entitled Powder Temperature Variation so the software expects you use the powder temperature but in most situations your powder will be the same temperature as the ambient temperature and it's pretty hard to actually measure the temperature of the powder.

There is no information that I've found that defines a limit to the Ba adjustment but I don't like to change my numbers by more than .1, most often I can get good results with far less of a change, more like plus or minus .02.

Before I start changing the Ba value (which can vary from lot to lot of the same powder) I make sure that I use the proper Shot Start Pressure value based on the recommendations that the software displays in a popup if you hold the your cursor over the value for a second or two.

The Weighting Factor is another value that I change before I start adjusting the Ba value. This represents the amount of powder that follows the base of the bullet. Most ballisticians use .5 (50% of the powder charge) as the standard value. You can change this up or down a couple tenths (.4 to .6). This value is just a guess and it is controlled by the case shape and powder characteristics, I don't know of any standard that specifies what this value should be in relation to the case or powder so it's just a guess.

When you decide to change the Ba value some people recommend changing the case capacity instead. I wont change the case capacity by more than half a grain if I've measured it.

A lot of these adjustments are going to be based on what input data you feel has a better chance of being correct. For example, if you have to choose whether to change the Ba value or the case capacity I'd base it on whether I know one or the other for a fact. If I've actually measured the case capacity (in accordance with the software manual's instructions) the I'd probably change the Ba value since I couldn't measure it.

Ned Ludd

Silver $$ Contributor

I use ambient temp, but am careful not to let the barrel heat up too much while measuring velocity. Measuring ambient temperature may not be perfect, but it is much simpler than trying to accurately measure barrel temperature, something many shooters are not equipped to do properly. I do use temperature strips on the side of the barrel near the action (https://www.mcmaster.com/temperature-strips/, Cat. #59535K13). These are not at all what I would call accurate, but they are an acceptable indication of when the barrel is sufficiently cooled to continue shooting. You can also simply place your hand on the barrel 2 to 4 inches in front of the action before you start shooting, then again while you fire a string, just to ensure the barrel isn't becoming noticeably warm to the touch. None of these methods is perfect, but they suffice for most people's needs. As with many things, I generally view simpler as better, even though the software is capable of far more than I actually use it for. Certainly for someone just learning to use the software, it may not be necessary to attempt to incorporate the most sophisticated capabilities at the very beginning.Thanks for taking the time for a comprehensive response.

I am hesitant to change Ba since I do not know the maximum amount of change that is reasonable.

Also I am unaware that temperature is an input! Is is ambient air temp or chamber temp?

As @rammac noted, the manual is a good place to start learning about the software and how to use it more proficiently. It can sometimes be a bit difficult to find a very specific piece of information, but it's a good resource nonetheless. It has a procedure for "calibrating" the software not too dissimilar from the rather simplistic method I described. It also provides estimates for the maximum adjustments to Ba that are advisable. The more you use the software, the better feel you will develop for making the appropriate adjustments, and the manual can be a big help in that process.

Last edited:

dellet

Gold $$ Contributor

I have checked velocity difference of gas/no gas by shooting with an adjustable block wide open and completely closed on multiple barrels of different lengths and gas tube lengths, The difference was less than shooting the same load in a bolt action. The variation was less than the same load used in two different rifles with the same barrel length, 20-30 fps.

fatelvis

Silver $$ Contributor

Where can you find the manual for Quickload? My program didn't come with one.The more you use the software, the better feel you will develop for making the appropriate adjustments, and the manual can be a big help in that process

I use ambient temp, but am careful not to let the barrel heat up too much while measuring velocity. Measuring ambient temperature may not be perfect, but it is much simpler than trying to accurately measure barrel temperature, something many shooters are not equipped to do properly. I do use temperature strips on the side of the barrel near the action (https://www.mcmaster.com/temperature-strips/, Cat. #59535K13). These are not at all what I would call accurate, but they are an acceptable indication of when the barrel is sufficiently cooled to continue shooting. You can also simply place your hand on the barrel 2 to 4 inches in front of the action before you start shooting, then again while you fire a string, just to ensure the barrel isn't becoming noticeably warm to the touch. None of these methods is perfect, but they suffice for most people's needs. As with many things, I generally view simpler as better, even though the software is capable of far more than I actually use it for. Certainly for someone just learning to use the software, it may not be necessary to attempt to incorporate the most sophisticated capabilities at the very beginning.

As @rammac noted, the manual is a good place to start learning about the software and how to use it more proficiently. It can sometimes be a bit difficult to find a very specific piece of information, but it's a good resource nonetheless. It has a procedure for "calibrating" the software not too dissimilar from the rather simplistic method I described. It also provides estimates for the maximum adjustments to Ba that are advisable. The more you use the software, the better feel you will develop for making the appropriate adjustments, and the manual can be a big help in that process.

Another temp collection method is an IR thermometer; however many don't know that surface emissivity (think reflection) affects accuracy of the measurement. A piece of black electrical tape will do.

-Mac

PS. I love quickload for my gas guns. Allows me to estimate port pressure when trying to load for an over or under gasses rifle or calculate a powder change for something like an M1 garand to not have op rod damage.

I recall a few years ago several experiments done to see velocity effect of gas port; I believe the result was that the gas port effect is less than barrel to barrel variation on muzzle velocity; and any other effects are seen in best up brass if timing of system is off.

The manual is a pdf file in the directory where the program was installed.Where can you find the manual for Quickload? My program didn't come with one.

I have to concur. There is not much increase in projectile velocity from the gas-bleed to the muzzle and the reduction due to the fact there is a gas-bleed will be within the error of QL anyhow.....there is very little effect on the muzzle velocity.

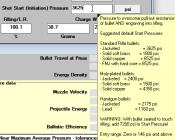

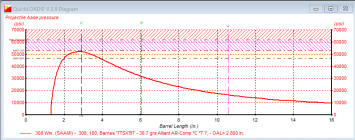

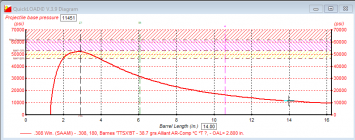

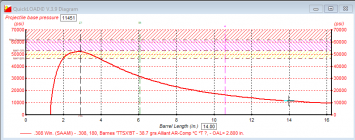

For those who want to estimate gas port pressure (the pressure at the barrel's gas port) take note that you can create a pressure curve that indicates pressure at the base of the bullet rather than chamber pressure (the default pressure).

After you have entered your load data and the software is displaying the results, select the menu item labeled

Change Diagram

For port pressure estimates I select

X Axis - Barrel Length (in)

Y Axis - Projectile Base Pressure (psi)

Apply and Exit

The graph will look something like this

This is a load I use in my short barreled rifles for hunting elk

If you drag your cursor along the pressure line, you will see the values appear and change as you drag the cursor.

In this case, if my gas port was positioned 2.25 inches short of the muzzle (on a 16.25 inch barrel) I'd have about 11,451 PSI of gas pressure at the port. In my M1A SOCOM you can have a port pressure of about 10,000 PSI plus or minus 2,000 PSI so this is close to the maximum but I've had no problems with the load so far and it works well out of my AR .308 which I use for hunting more often than the SOCOM.

Most people refer to the muzzle pressure as a general guideline for the port pressure but in this case the muzzle pressure is estimated to be around 9,471 PSI, lower than the low end of the port pressure range so you might be tempted to increase the load pressure which would result in even higher port pressure.

P.S. I made several mistakes trying to explain this and this is the correct edited version of my post. The second image shows a 16.25 inch barrel and the proper port position is 2.25 inches from the muzzle. The pressures are the correct values.

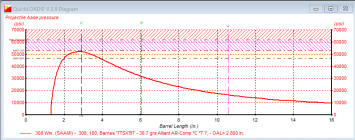

After you have entered your load data and the software is displaying the results, select the menu item labeled

Change Diagram

Select Optional diagrams

A window opens that allows you to select all kinds of options for the graphical display.

For port pressure estimates I select

X Axis - Barrel Length (in)

Y Axis - Projectile Base Pressure (psi)

Apply and Exit

The graph will look something like this

This is a load I use in my short barreled rifles for hunting elk

If you drag your cursor along the pressure line, you will see the values appear and change as you drag the cursor.

In this case, if my gas port was positioned 2.25 inches short of the muzzle (on a 16.25 inch barrel) I'd have about 11,451 PSI of gas pressure at the port. In my M1A SOCOM you can have a port pressure of about 10,000 PSI plus or minus 2,000 PSI so this is close to the maximum but I've had no problems with the load so far and it works well out of my AR .308 which I use for hunting more often than the SOCOM.

Most people refer to the muzzle pressure as a general guideline for the port pressure but in this case the muzzle pressure is estimated to be around 9,471 PSI, lower than the low end of the port pressure range so you might be tempted to increase the load pressure which would result in even higher port pressure.

P.S. I made several mistakes trying to explain this and this is the correct edited version of my post. The second image shows a 16.25 inch barrel and the proper port position is 2.25 inches from the muzzle. The pressures are the correct values.

Last edited:

I am hesitant to change Ba since I do not know the maximum amount of change that is reasonable.

If you simply use you MV numbers from your chrono as a guide, that helps you make the adjustment. The result may not be consistent with other loads where you've made changes in the cartridge specs (like seating depth), but as you collect more data and make some other adjustments (like temperature, weighting factor, or even the actual case volume of a fired case you've measured) you'll get more consistency. But, just remember, the results in QuickLoad is not very precise and does help you stay in the ball park.

Also I am unaware that temperature is an input! Is is ambient air temp or chamber temp?

I've used my infrared thermometer to measure the temperature of my cases, but for the most part (if the cases are not just sitting in the direct hot sunlight) the ambient air temp works just fine.

Of course, if you happen to leave cartridge in a hot chamber for very long before firing, that case and powder is going to heat up. A gas gun makes this issue a little more difficult to manage than for a bolt gun. So, just be aware of that time the cartridge is sitting in the chamber as you're prepare to fire a shot.

Last edited:

But, just remember, the results in QuickLoad is not very precise and does help you stay in the ball park

I disagree and so do several reloading manual authors. Quickload is as precise as you are, garbage in - garbage out. My adjusted numbers will hold to within 30 FPS of actual measured velocities over a couple of grains of powder charge change. That's within the margin or error for most of the common chronographs on the market so you can't really expect any better results unless you've got access to a very precise chronograph. To get any better pressure numbers you'd have to use a pressure transducer and that would only help provide numbers for the pressure at one location along the barrel ( as long as you calibrated the system properly). RSI actually uses Quickload in conjunction with their equipment and software to help find accuracy nodes and pressure data.

I disagree and so do several reloading manual authors. Quickload is as precise as you are, garbage in - garbage out.

You're absolutely right about that.

My adjusted numbers will hold to within 30 FPS of actual measured velocities over a couple of grains of powder charge change.

I guess we have a different idea of what "precise" is.

You're absolutely right about that.

I guess we have a different idea of what "precise" is.

I wouldn't know, what do you consider precise?

By the way, if we are talking about muzzle velocities then we are discussing accuracy, not precision (I figured I'd better be more careful with the words I use).

Since I only own an cheap chronograph (I'm not very wealthy) I can only expect that my muzzle velocities may be off by about 1% or so (20 to 30 FPS) from the true average muzzle velocity. So I can't really expect any better accuracy from Quickload since I can't verify it any closer to the actual muzzle velocity anyways.

Since I only own an cheap chronograph (I'm not very wealthy) I can only expect that my muzzle velocities may be off by about 1% or so (20 to 30 FPS) from the true average muzzle velocity. So I can't really expect any better accuracy from Quickload since I can't verify it any closer to the actual muzzle velocity anyways.

Similar threads

- Replies

- 2

- Views

- 492

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.