I tend to agree with LVLAaron. That seems like a pretty stout load of Varget for .308 Win setup [NOTE: I'm assuming a .308 Win here, but if you're using one of the larger cartridge .30 cal RPR rifles, those charge weights would be way off on the low side and I'm not sure Varget would be the best powder choice, anyhow]. What have you done previously with regard to optimizing charge weight? If you're running at or over MAX pressure, seating depth testing can be misleading as groups can sometimes be very erratic.

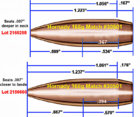

The second question I have is with regard to your seating depth measurements. Again, I'm assuming a .308 Win here, so if I'm incorrect on that, please give us a little more info on your setup. Presumably, you using COAL measurements for your seating depths, not CBTO. Regardless, something doesn't seem right. By my calculations, the shank of a 185 Juggernaut seated in a .308 Win case at a COAL of 3.260" would actually be out of the neck, or very close to it. Are you actually using COAL measurements for your seating depth? Or CBTO? I'm just trying to figure out exactly what you're doing here so as to possibly provide better feedback on your seating depth testing.

On a more general note, your approach to seating depth testing appears to have been using a very coarse increment test first, to find a narrower region in which to test further. You selected the region around 3.250", which looks like the place to be. However, in your fine increment test, you are using .005" test increments. In my experience, .005" increments are still pretty coarse, especially for a .308 Win. I would suggest using .003" increments.

The whole point of doing a fine increment seating depth test is to identify an "optimal window" where precision is the best, and then load to somewhere between the leading edge and the middle of that window (i.e. choose a seating depth from somewhere between the longest seated rounds to the middle length rounds in the optimal window, not the shortest). That will give you the most headroom for land erosion before you will need to re-visit seating depth again. What you're looking for in the "optimal window" is at least two to three successive .003" increments that all give the best/tightest grouping. That way, you have defined both the leading and trailing edges of the "optimal window", as well as the middle. If you test in larger increments, such as .005", it is not uncommon to see what appears to be a single tight group at one seating depth increment, that opens up in the seating depth increments to either side. In other words, it's easy to miss the the optimal window if you test in increments that are too coarse.

With that idea in mind, I'd suggest testing between 3.240" and 3.255" using .003" increments (i.e. 3.240", 3.243", 3.246", 3.249", 3.252", 3.255"). This is only a guess, but I wouldn't be surprised if the groups tightened up from 3.243" to 3.246"/3.249". That would then be your "optimal window", and I'd would probably load to 3.243" or 3.246". In any event, I think you see where I'm going with the finer increment testing idea. When you only see one seating depth that groups well, and the groups to either side open up, it can be very difficult to make an informed choice.