Yes changing probe length messes with readings just a question have you or anyone else here after indicating range rod removed it and reinserted it and rechecked t.i.r.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

indicating a barrel for chambering ?

- Thread starter Danny1788

- Start date

Check twice cut one time LarryYes changing probe length messes with readings just a question have you or anyone else here after indicating range rod removed it and reinserted it and rechecked t.i.r.

double check is great but did you remove range rod and reinsert and check at two points or rechecked with an indicater at two points after using range rod which just sits on top of lands and what did you find when checking groove dia.'s

Make sure your not bending the barrel with the outside spiders . LarryCheck twice cut one time Larry

exactly what chuck strain isMake sure your not bending the barrel with the outside spiders . Larry

Correct . Larryexactly what chuck strain is

carlsbad

Lions don't lose sleep over the opinions of sheep.

Your data, as you presented it, says the barrel isn't straight. Bending the barrel occurs when you use a 4 jaw chuck and a spider. since you have point contact at both ends, I wouldn't worry about that.

I would check again 1" 2" and 3" in on both ends. there is a reason you generally cut off a bit of the muzzle end.

--Jerry

I would check again 1" 2" and 3" in on both ends. there is a reason you generally cut off a bit of the muzzle end.

--Jerry

I never have see a straight bore in a barrel . Yes you can bend a barrel with a 4 jaw chuck and spiders . The bore is where you check the Straigness from . LarryYour data, as you presented it, says the barrel isn't straight. Bending the barrel occurs when you use a 4 jaw chuck and a spider. since you have point contact at both ends, I wouldn't worry about that.

I would check again 1" 2" and 3" in on both ends. there is a reason you generally cut off a bit of the muzzle end.

--Jerry

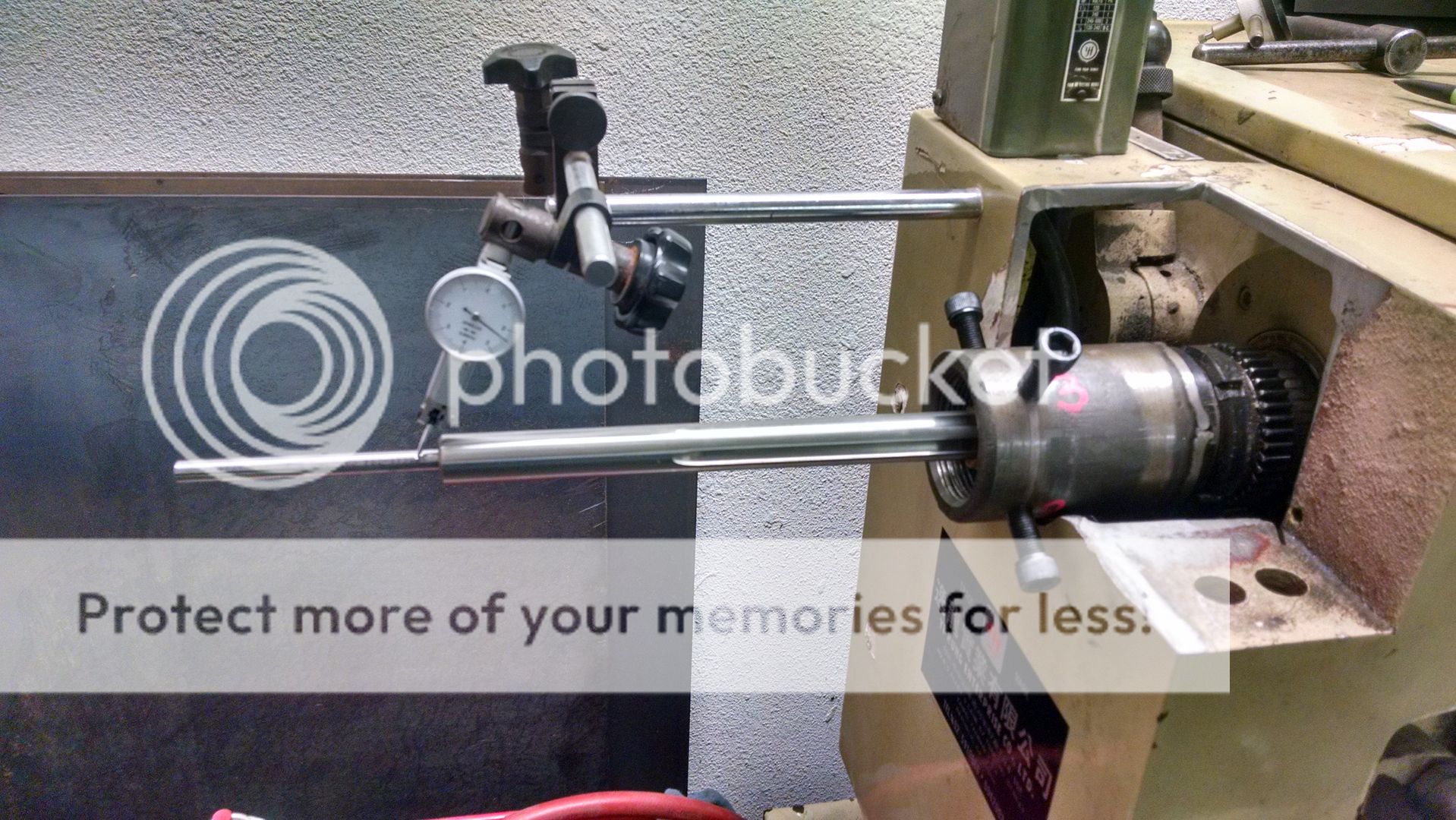

So I'm about to chamber up a new 7mm brux barrel and I'm a little stumped. Normally I just use a range rod with the proper fit bushing and dial in the barrel on the chamber/breech end with my mitutoyo .0001" Indicator to as close to zero run-out as I can get and don't worry about the muzzle runout. this was my normal way of chambering and I index the muzzle to 12oclock.

This time I used my mitutoyo .0001" dial with a 2.8" long tip. I dialed in the bored at the breech and then about 2.6" in to the barrel. I was dialing in on the groove and got it running damn near zero runout at both spots.

the muzzle end of the barrel was running about .050" out of round and you could visibly see the barrel was way out of being concentric at the muzzle end.

so I grabbed my range rod and .0001 indicator and dialed the muzzle end into about .0001" runout

I then went back and checked the far chamber end and it was still running almost zero run-out. I then ran the long indicator into the bore about 2.6" and it had a measured run-out of +.0005" now.

SO what is the best way to go about this? I'm still learning and I'm not sure if I should chamber it with zero runout at the breech and 2.6" in or should I get the muzzle dialed in and the breech and don't worry about the run-out 2.6" in from there?

I found this link quite helpful. Good videos.

http://shortactioncustoms.com/videos-2/

Phil

Mark at Short Action Customs is at the top of his game. Some very informative videos from a very talented Smith.

Regards, Paul

www.boltfluting.com

Regards, Paul

www.boltfluting.com

butchlambert

Site $$ Sponsor

Mark at Short Action Customs is at the top of his game. Some very informative videos from a very talented Smith.

Regards, Paul

www.boltfluting.com

If I measured my reamed chamber and it showed runout. Can you explain to me what could cause this? I think it would be very difficult to produce run out.

butchlambert

Site $$ Sponsor

double check is great but did you remove range rod and reinsert and check at two points or rechecked with an indicater at two points after using range rod which just sits on top of lands and what did you find when checking groove dia.'s

This is why I use Deltronic pins. I never get the same reading after reinserting a range rod.

Why is that?This is why I use Deltronic pins. I never get the same reading after reinserting a range rod.

butchlambert

Site $$ Sponsor

Why is that?

Well the bushing that fits the range rod needs to be .0002" smaller than the bore to to be able to slip it in and the bushing needs to be about .0002 larger than the part of the rod it slides onto. I think that allows error there. Now if the bore isn't straight it will be leaning further. I'm not sure the rods are that straight after a couple uses. Try it as George said. I have and mine just stays in the drawer.

Last edited:

he might be on top of his game but that radius at the end of the chamber is a big no noMark at Short Action Customs is at the top of his game. Some very informative videos from a very talented Smith.

Regards, Paul

www.boltfluting.com

I usually do not double check after chambering but I think I will add this to my protocol and see what shows up. Probably too late to fix anything but it will be interesting to see. Thanks Butch.Well the bushing that fits the range rod needs to be .0002" smaller than the bore to to be able to slip it in and the bushing needs to be about .0002 larger than the part of the rod it slides onto. I think that allows error there. Now if the bore isn't straight it will be leaning further. I'm not sure the rods are that straight after a couple uses. Try it as George said. I have and mine gust stays in the drawer.

If I measured my reamed chamber and it showed runout. Can you explain to me what could cause this? I think it would be very difficult to produce run out.

Butch,

A few things come to mind. Curvature in the bore, tailstock alignment issues, reamer not cutting on all flutes, reamer with build up on the leading edge. Just things that I have experienced personally.

Paul

www.boltfluting.com

butchlambert

Site $$ Sponsor

Butch,

A few things come to mind. Curvature in the bore, tailstock alignment issues, reamer not cutting on all flutes, reamer with build up on the leading edge. Just things that I have experienced personally.

Paul

www.boltfluting.com

Basically you are saying poor machine practice and improper set up would do it? I guess we need to determine what runout that you are speaking of as it can be a couple things. Are you speaking chamber runout to the bore-groove or your chamber has runout itself?

One thing that I did notice on Mark's video is that he is using a rigid setup. If you were slightly off center the reamer would act like a boring bar so to speak. So, with his setup, he should have virtually no run out. Just an observation.

Paul

www.boltfluting.com

Paul

www.boltfluting.com

Similar threads

- Replies

- 52

- Views

- 4,155

- Replies

- 71

- Views

- 4,360

- Replies

- 119

- Views

- 11,922

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.