So I'm about to chamber up a new 7mm brux barrel and I'm a little stumped. Normally I just use a range rod with the proper fit bushing and dial in the barrel on the chamber/breech end with my mitutoyo .0001" Indicator to as close to zero run-out as I can get and don't worry about the muzzle runout. this was my normal way of chambering and I index the muzzle to 12oclock.

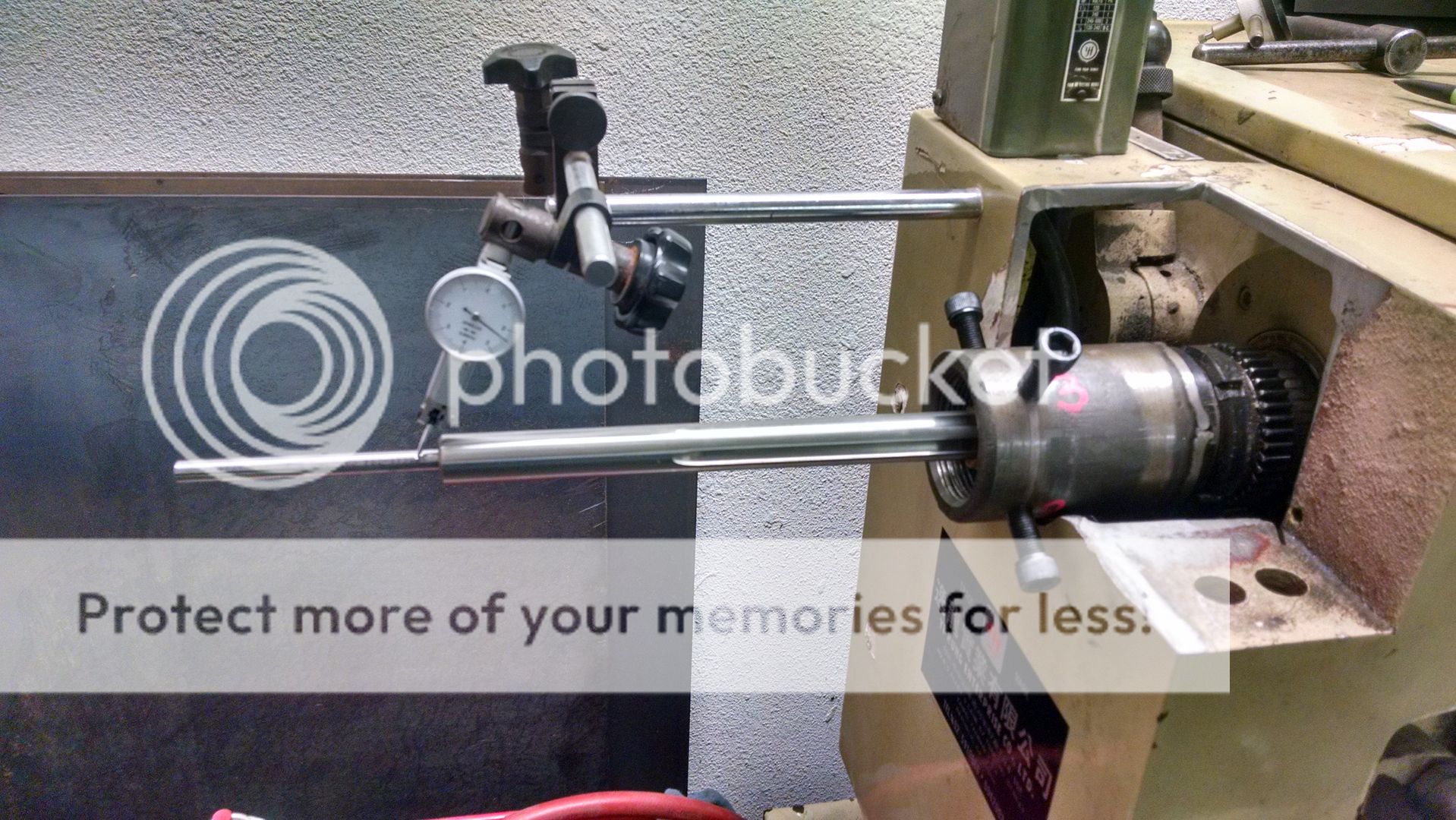

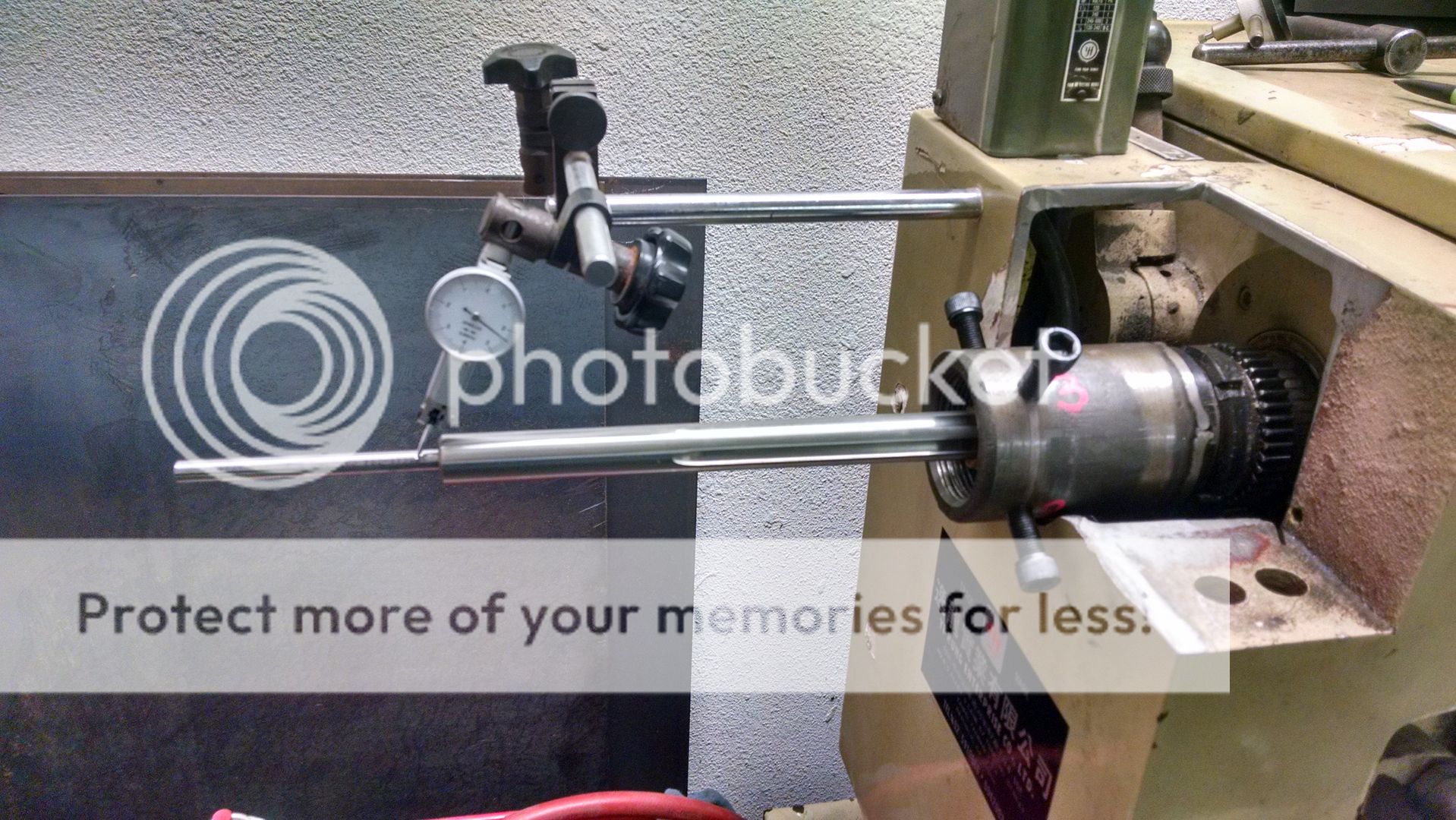

This time I used my mitutoyo .0001" dial with a 2.8" long tip. I dialed in the bored at the breech and then about 2.6" in to the barrel. I was dialing in on the groove and got it running damn near zero runout at both spots.

the muzzle end of the barrel was running about .050" out of round and you could visibly see the barrel was way out of being concentric at the muzzle end.

so I grabbed my range rod and .0001 indicator and dialed the muzzle end into about .0001" runout

I then went back and checked the far chamber end and it was still running almost zero run-out. I then ran the long indicator into the bore about 2.6" and it had a measured run-out of +.0005" now.

SO what is the best way to go about this? I'm still learning and I'm not sure if I should chamber it with zero runout at the breech and 2.6" in or should I get the muzzle dialed in and the breech and don't worry about the run-out 2.6" in from there?

This time I used my mitutoyo .0001" dial with a 2.8" long tip. I dialed in the bored at the breech and then about 2.6" in to the barrel. I was dialing in on the groove and got it running damn near zero runout at both spots.

the muzzle end of the barrel was running about .050" out of round and you could visibly see the barrel was way out of being concentric at the muzzle end.

so I grabbed my range rod and .0001 indicator and dialed the muzzle end into about .0001" runout

I then went back and checked the far chamber end and it was still running almost zero run-out. I then ran the long indicator into the bore about 2.6" and it had a measured run-out of +.0005" now.

SO what is the best way to go about this? I'm still learning and I'm not sure if I should chamber it with zero runout at the breech and 2.6" in or should I get the muzzle dialed in and the breech and don't worry about the run-out 2.6" in from there?