Alexander-M

Gold $$ Contributor

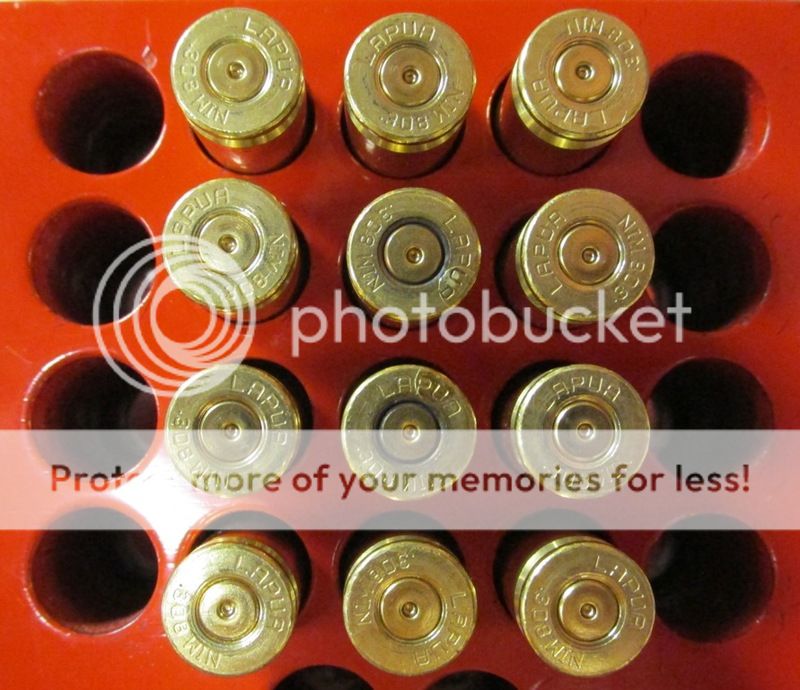

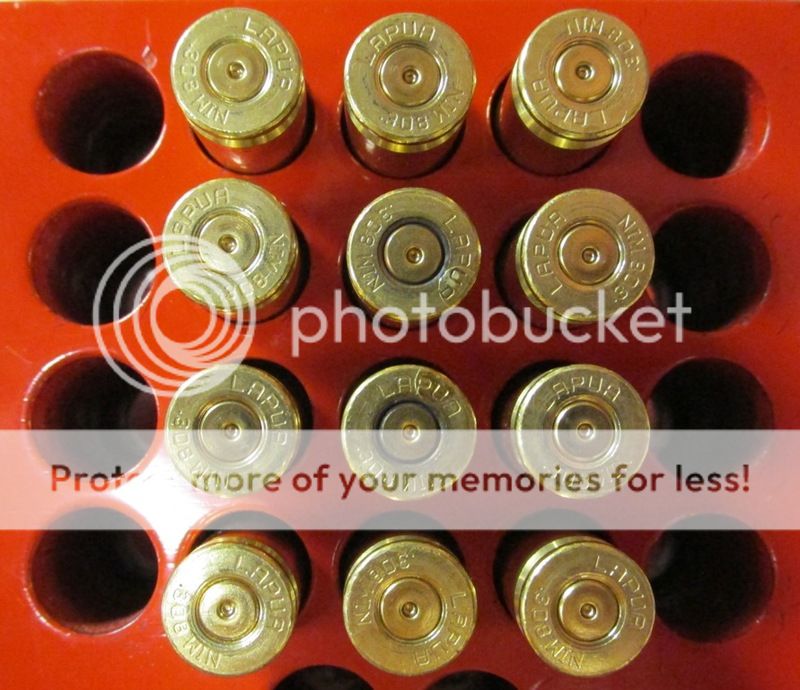

After shooting 184 rounds of 308 Win consisting of 2X Fired Lapua brass with 185gr Juggernauts, 44.40 gr Varget and KVB-7's in a match, I found two cases that had a black ring around the primer. At first, this black ring was all I saw, and suspected over sized primer pockets. But after taking the picture, below, the ejector marks became obvious, which would indicate an over pressure condition.

In the picture, the two spent cases in questions are in the middle, surrounded by 10 other cases that looks just like the all the other spent cases; i.e., no black ring and no ejector mark.

What could have caused this over pressure?

Powder Charge: I trickle every charge using an FX-120i scale, and while the great majority register 44.40 when I fill the case, I occasionally use a 44.42 gr charge instead of removing one kernel, or starting from scratch. Even if the charge were as high as 44.40 gr, I doubt if it would be enough to cause the signs of over pressure.

Heat: Yes, it was hot, and the barrel was sizzling. However, although I do drop the rounds in the chamber as soon as I eject the spent cases, I make a point of not closing the bolt until I am ready to shoot; I may shoot two to three seconds after I close the bolt. There were occasions when I had to stop to readjust the bipod, or in many more cases, to wipe the sweat off my eyes. But when I did this, I opened the bolt. Perhaps I should have removed the rounds from the chamber in these circumstances?

What is your opinion?

Thanks!

Alex

In the picture, the two spent cases in questions are in the middle, surrounded by 10 other cases that looks just like the all the other spent cases; i.e., no black ring and no ejector mark.

What could have caused this over pressure?

Powder Charge: I trickle every charge using an FX-120i scale, and while the great majority register 44.40 when I fill the case, I occasionally use a 44.42 gr charge instead of removing one kernel, or starting from scratch. Even if the charge were as high as 44.40 gr, I doubt if it would be enough to cause the signs of over pressure.

Heat: Yes, it was hot, and the barrel was sizzling. However, although I do drop the rounds in the chamber as soon as I eject the spent cases, I make a point of not closing the bolt until I am ready to shoot; I may shoot two to three seconds after I close the bolt. There were occasions when I had to stop to readjust the bipod, or in many more cases, to wipe the sweat off my eyes. But when I did this, I opened the bolt. Perhaps I should have removed the rounds from the chamber in these circumstances?

What is your opinion?

Thanks!

Alex