I had a skinny carbon barrel give me fits a few weeks ago. I don't remember the brand, but it was .750 at the muzzle--often a recipe for disaster. Wasn't all that straight when I dialed it in, but the big problem was the bore size at the breech.

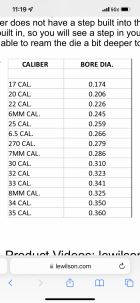

I use Grizzly rods with bushings to figure out what size to use on the reamer. Most barrels are larger at the breech then tighten a little around an inch in or so. This one, a 30 cal, was .2998 for the first half inch, then slowly jjjjopened up to .3004 at about 2".

I started chambering and checked after a half inch or so. Chatter all over the place. I went with a larger bushing which helped a little, but still had chatter. Went larger with the bushing again but still chatter.

We happened to have a second JGS 300 Norma reamer--ordered by mistake, so I grabbed that reamer and put the largest bushing I could--IIRC it was a .3004. That fixed it.

I threaded the muzzle and timed the brake, then sent the rifle over to be bedded, engraved, and cerakoted--I don't have to do that part. My boss--not knowing the troubles I'd had--took it out for load development. He shot it one time and decided he didn't have time to work on it any more--too much time out of the shop hunting I guess.

So I took it to the range for the next set of loads last Friday. I shoot better than my young boss anyway--as he admits. With the next loads he wanted to try, two different bullets, wound up shooting what look to be .3s. 3120ish with 212 ELDXs and 3040ish with 225 ELDMs. Both of those groups in obvious nodes.

That was out of a chassis, and I hate chassis. Chassis, heavier recoiling rifles, and light contour carbon barrels often don't work well together. Add to that all the chambering troubles and I was sure I was going to have to spin up another barrel. This one shoots great. Go figure......

I use Grizzly rods with bushings to figure out what size to use on the reamer. Most barrels are larger at the breech then tighten a little around an inch in or so. This one, a 30 cal, was .2998 for the first half inch, then slowly jjjjopened up to .3004 at about 2".

I started chambering and checked after a half inch or so. Chatter all over the place. I went with a larger bushing which helped a little, but still had chatter. Went larger with the bushing again but still chatter.

We happened to have a second JGS 300 Norma reamer--ordered by mistake, so I grabbed that reamer and put the largest bushing I could--IIRC it was a .3004. That fixed it.

I threaded the muzzle and timed the brake, then sent the rifle over to be bedded, engraved, and cerakoted--I don't have to do that part. My boss--not knowing the troubles I'd had--took it out for load development. He shot it one time and decided he didn't have time to work on it any more--too much time out of the shop hunting I guess.

So I took it to the range for the next set of loads last Friday. I shoot better than my young boss anyway--as he admits. With the next loads he wanted to try, two different bullets, wound up shooting what look to be .3s. 3120ish with 212 ELDXs and 3040ish with 225 ELDMs. Both of those groups in obvious nodes.

That was out of a chassis, and I hate chassis. Chassis, heavier recoiling rifles, and light contour carbon barrels often don't work well together. Add to that all the chambering troubles and I was sure I was going to have to spin up another barrel. This one shoots great. Go figure......