I depends on how you dial a barrel in.

If you only dial in the first few inches you may not have any problem but if the bore is slightly out at some point the pilot will follow that curve and whatever it is out it will be doubled by the reamer at some point.

if it only drifts .0005 then the pilot fitment will probably accommodate if it drifts. 001 you will get an enlarged chamber by .001 if it drifts .002 the reamer will be forced off target by .0015 wich turns into .003 if your pilot fit the reamer with a .0005 slip fit.

This can happen. it may not depending on fitment and other factors affecting you tools,lathe,reamer holder/pusher.

I've seen all kinds of thing happen when we dont see all things affecting our work.

Experience a being a big one or lack of.

youre right its all up to your pusher. but when you can have multiple chambers exactly the same then you know youre doing right- doesnt matter how you get there but you need to be able to check your work

I’m gonna bring an old thread to the top, as a lot can be learned from this.

Does anyone worry about work hardening the stainless barrels with the drilling and boring process?

I’ve chambered using a prebore, and I feel like the throats come out looking better on the barrels I’ve done with just using the finish reamer the entire way with a pressure oil flush.

Im curious if anyone else is using piloted core drills from JGS and how you are liking them?

I've never experienced it. I use core drills but not piloted.

Dave Why do you like a core drill better than a regular drill bit to pre drill with ?

Thanks

Hal

Here's what I did with AI 40' chambers. Start by running the finish reamer in until you have about .050" of the body in. Then rough it out whatever way you feel comfortable with. I never bored on a taper after that.

I like that. I pre-drill/bore. I don't have a chatter problem with steel cutters, but I have a carbide reamer that is SUPER unhappy about the shoulder meeting the sharp corner of the pre-bore. I reckon that you're describing would be an easy way to soften the start a little bit.

It swung around and gouged a piece out

View attachment 1092648

View attachment 1092648

I wouldn't hold a reamer in my hand on a bet.

I am astounded people do it.

I tried it ONCE. JGS reamer holder for me. I like my fingers right where they are...

Dave Why do you like a core drill better than a regular drill bit to pre drill with ?

Thanks

Hal

Faster. Removes more material.

I make sure the muzzle and throat a running dead nuts.tail stock alignment perfect also.drill,prebore.now the reamer is starting perfect.smooth feed on tail stock with oil flushing system .no chatter and Chambers come out excellent.people set up and chamber differently but this works great for me.

I use a number of the JGS piloted core drills and they are great! I can get 20 chambers done just using the finish reamer. 100 if I use a rougher or a core drill. Doing a Norma Mag chamber only takes about 15 minutes with the core drill and finish reamer.

I use a number of the JGS piloted core drills and they are great! I can get 20 chambers done just using the finish reamer. 100 if I use a rougher or a core drill. Doing a Norma Mag chamber only takes about 15 minutes with the core drill and finish reamer.

Do you prefer spiral or straight flute roughers?

Dave Why do you like a core drill better than a regular drill bit to pre drill with ?

Thanks

Hal

I'm of the school that a true, concentric bore/roughed in chamber is the ONLY way to guarantee a concentric chamber. Bushings and floating reamer holders just provide false hope things will turn out well. I have the advantage of chambering on a Haas TL-1 with a tool post. All tooling is held rigid except when I push the finish reamer in. Is everything in perfect alignment? Of course not. I hold my core drills in a drill chuck. I dial in the neck/pilot area to +/- .0005". The body on the rear is usually within a couple of thou. The neck/shoulder area, even if it's out of alignment slightly will follow the bore. Tools flex. The rear, which is much more rigid, acts like a single point tool and cuts a very concentric hole. I then have a concentric hole for the finish reamer to follow. The same concentric hole can be attained with a twist drill and preboring. Just more work and more wear on the finish reamer. For me, a core drill is the quickest and best way to rough in a chamber. I've used a core drill on a manual machine a few times and the only compromise is the lose of rigidity on the rear.

Do you prefer spiral or straight flute roughers?

The JGS core drills are spiral. I no longer spend the money for a rougher, I buy the core drill instead. If it is a low volume cartridge (<20 barrels) I just use the finish reamer. No predrilling or boring.

So...40 years as a contractor and a core drill has always been what's essentially a hole saw...usually diamond to cut holes in concrete.

They're not on JGS's price sheet- what is, what you guys are referring to as a core drill?

Since we're on the subject, I've always wondered about optimum drill type- my concern is the angle of the drill point. When boring after drilling, the "point" isn't touched. 135 degree is best for hard materials (steel), but my thinking is that a more gradual angle/ transition for the finishing reamer to engage is better and use a 118 degree. If anyone cares to opine on this...

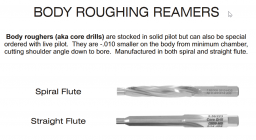

Body reamers "AKA core drills" in the catalog.

^^^

Thanks. Dunno 'bout that one, for me. I just don't see the cost/benefit being there for $270 given they're chamber specific, JMO and I may still be missing something.

Might make more sense for high-volume work to spread that cost over many chambers.

.010 under seems to be cutting it really close- too close for my own taste. Anything more than the skinniest of passes with the boring bar after it's drilled, and the chamber's trashed.

I don't know why you would want to bore it if you are using one of these.

^^^

Thanks. Dunno 'bout that one, for me. I just don't see the cost/benefit being there for $270 given they're chamber specific, JMO and I may still be missing something.

Might make more sense for high-volume work to spread that cost over many chambers.

.010 under seems to be cutting it really close- too close for my own taste. Anything more than the skinniest of passes with the boring bar after it's drilled, and the chamber's trashed.

They're made semi production work. I can rough 300+ chamber with HSS. I haven't tried them in carbide. Besides getting great results I can rough out a chamber in a about 1 1/2 minutes run time.

^^^

Thanks. Dunno 'bout that one, for me. I just don't see the cost/benefit being there for $270 given they're chamber specific, JMO and I may still be missing something.

Might make more sense for high-volume work to spread that cost over many chambers.

.010 under seems to be cutting it really close- too close for my own taste. Anything more than the skinniest of passes with the boring bar after it's drilled, and the chamber's trashed.

You wouldn't use a boring bar. You'd go in with the core drill and then the finish reamer.

You wouldn't use a boring bar. You'd go in with the core drill and then the finish reamer.

why wouldn’t the core drill have the same problem as wander/flex as any normal spiral stub drill? Even carbide and colbalt drill bits flex